产品描述

L 系列智能伺服驱动器是基于直流电源供电的系列高性能有刷或无刷电机驱动器,可以实现位置、速度和力矩控制。驱动器可以通过CANopen

实现分布式控制,也提供了模拟或数字指令接口,以实现单机运行模式。

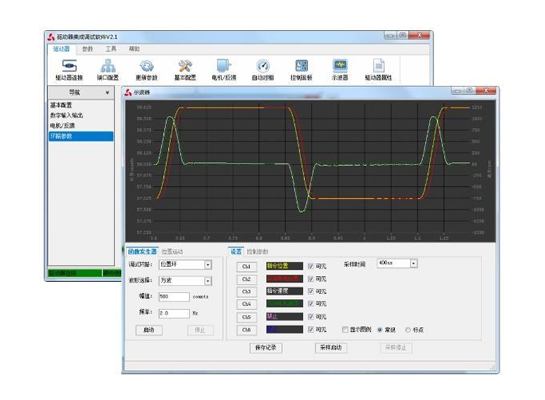

专用的SME集成调试软件,基于Windows环境,简单易用,可以很方便地设置驱动器参数,进行系统调试和性能评估。

产品参数

| 型号 | SDM-4805 | SDC-6005/10-M | SDC-6005/10 | ||

|---|---|---|---|---|---|

| 供电电压Vcc | 12~55VDC | 12~65VDC | 12~65VDC | ||

| 最大输出电压 | 0.9×Vcc | 0.9×Vcc | 0.9×Vcc | ||

| 最大输出电流 | 10A(<1s) | 10A | 20A | 10A | 20A |

| 连续输出电流 | 5A | 5A | 10A 5A | 10A | |

| 控制模式 | 位置/速度/力矩 | 位置/速度/力矩 | 位置/速度/力矩 | ||

| 功率级开关频率 | 50kHz | 50kHz | 50kHz | ||

| 电流环刷新频率 | 25kHz(40μs) | 25kHz(40μs) | 25kHz(40μs) | ||

| 速度环刷新频率 | 2.5kHz(400μs) | 2.5kHz(400μs) | 2.5kHz(400μs) | ||

| 位置环刷新频率 | 2.5kHz(400μs) | 2.5kHz(400μs) | 2.5kHz(400μs) | ||

| 最大速度(1对极) | 60000rpm | 60000rpm | 60000rpm | ||

| 输入信号 | |||||

| 数字霍尔传感器 | H1,H2,H3 | H1,H2,H3 | H1,H2,H3 | ||

| 编码器 | A/B/I差分或单端,最大5MHz | A/B/I差分或单端,最大5MHz; 可选Biss-C/SSI、旋转变压器; | |||

| 数字输入 | 10路(其中5路高速) | 6路 | 6路 | ||

| 模拟输入 | 1路差分或单端,±10V | 1路差分或单端,±10V | 1路差分或单端,±10V | ||

| 输出信号 | |||||

| 数字输出 | 3路 | 4路 | 4路 | ||

| 通讯接口 | |||||

| RS232 | 最大115200bps | TTL,2路,最大115200bps | RS232,最大115200bps, RS485,可选 | ||

| CANopen | 最大1Mbps | 最大1Mbps | 最大1Mbps | ||

| 环境条件 | |||||

| 工作温度 | -40~+55℃ | -40~+55℃ | -40~+55℃ | ||

| 工作湿度 | 5~95%,无凝露 | 5~95%,无凝露 | 5~95%,无凝露 | ||

| 存储温度 | -40~+85℃ | -40~+85℃ | 40~+85℃ | ||

| 结构数据 | |||||

| 重量 | 40g | 75g | 105g | ||

| 尺寸 | 63.5×40.6×21.0mm | 55.0×46.5×22.0mm | 64.0×46.5×37.5mm | ||

| 安装 | 插针式接口,螺钉锁紧 | 插针式接口,螺钉锁紧 | 模块式,螺钉锁紧 | ||

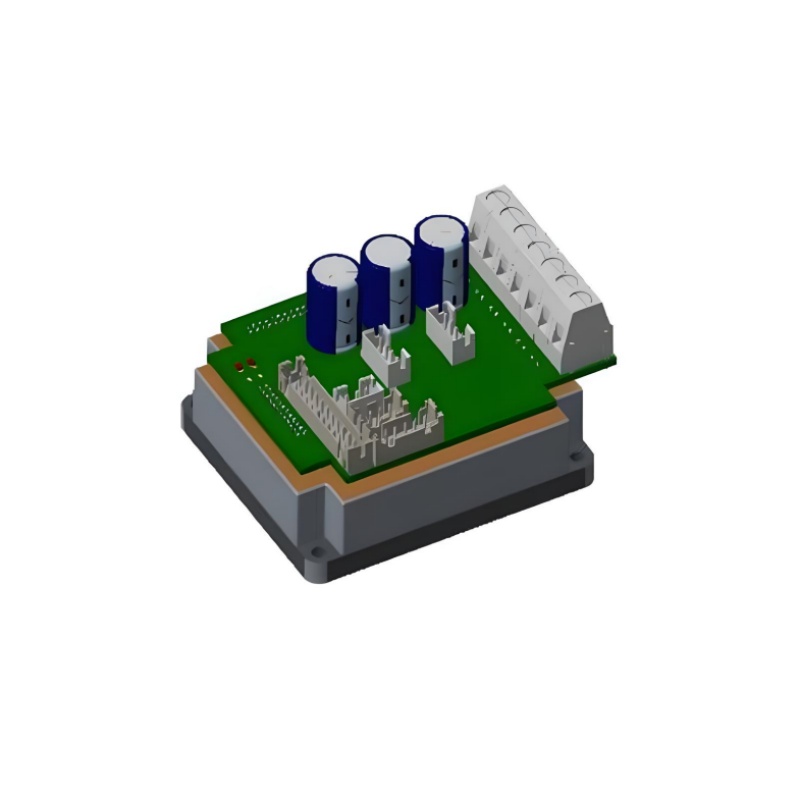

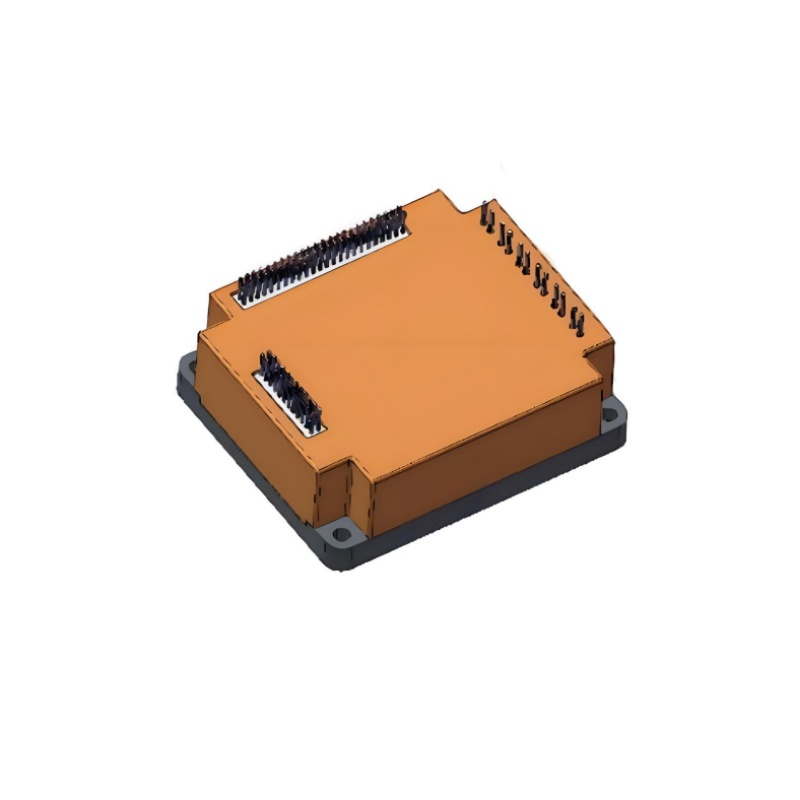

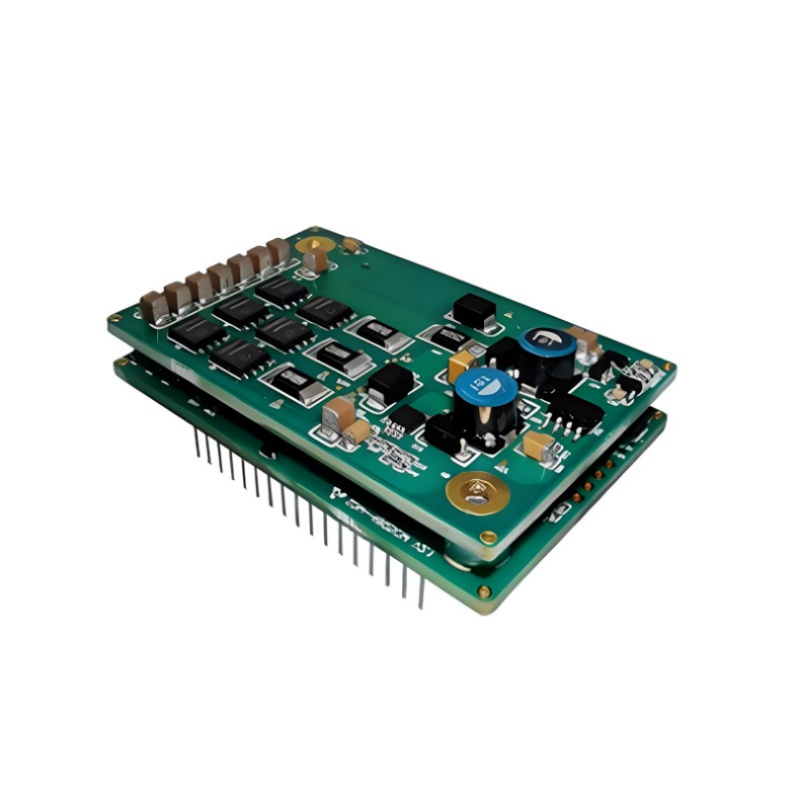

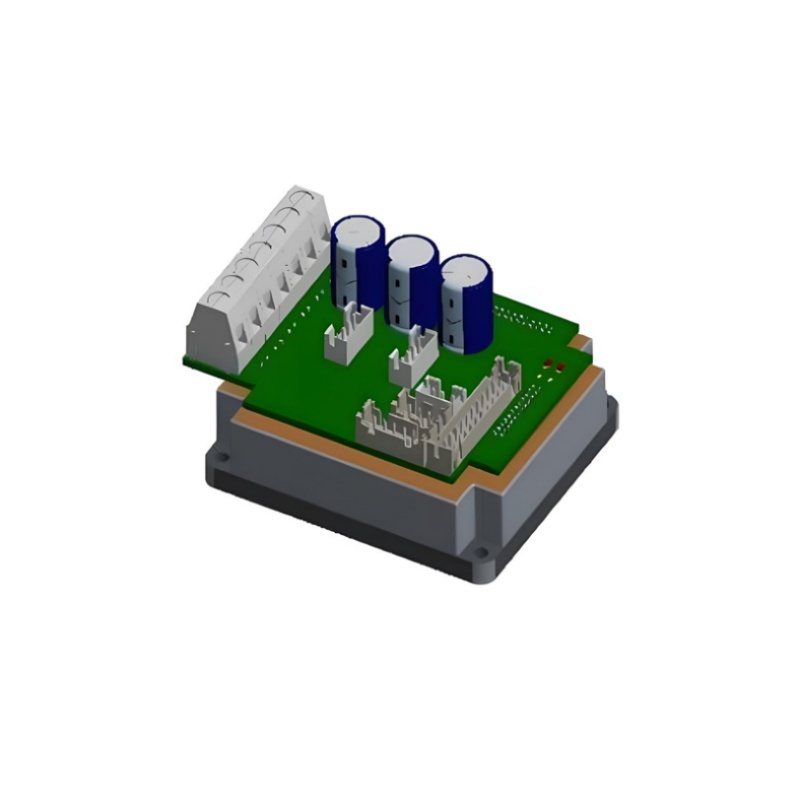

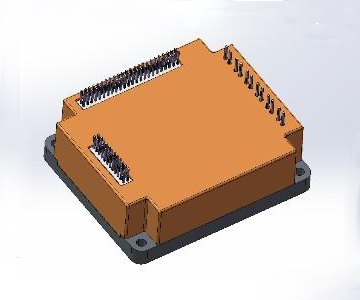

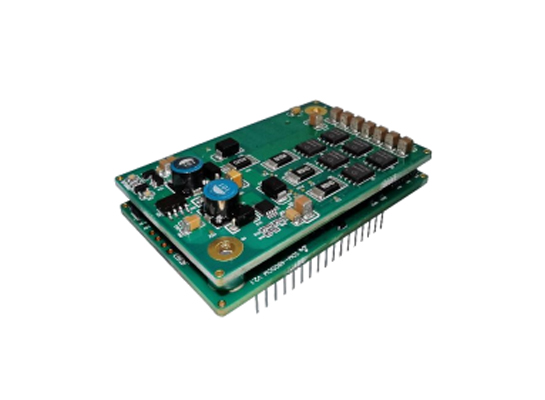

产品展示

指令与通讯

- 步进脉冲;

- 模拟量位置、速度、转矩

- PWM速度、转矩

- CANopen、RS232、RS485

反馈

- 数字霍尔

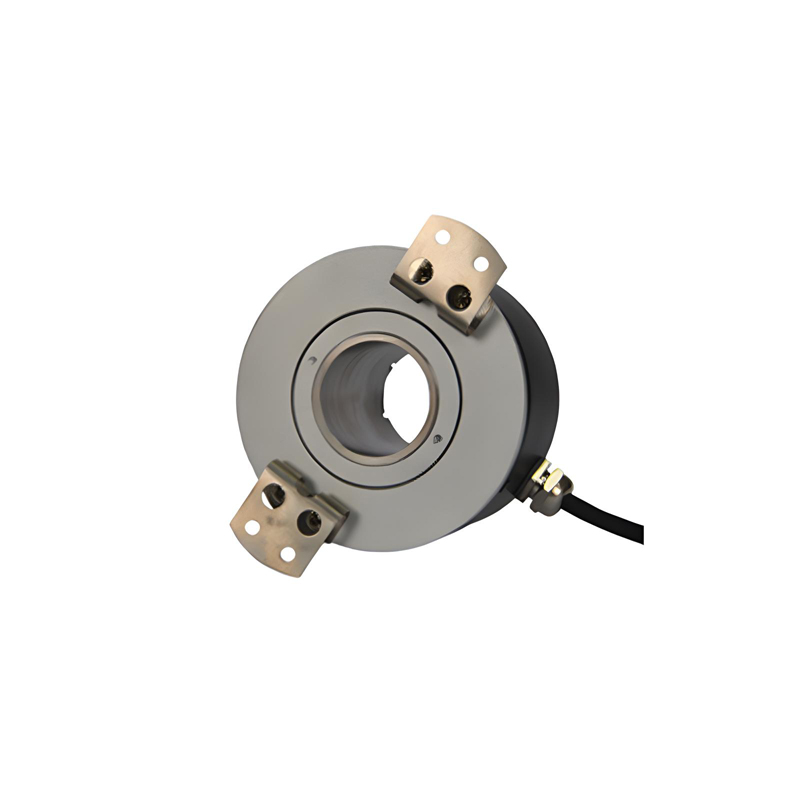

- 正交增量编码器

- Biss-C/SSI 编码器

- 旋转变压器

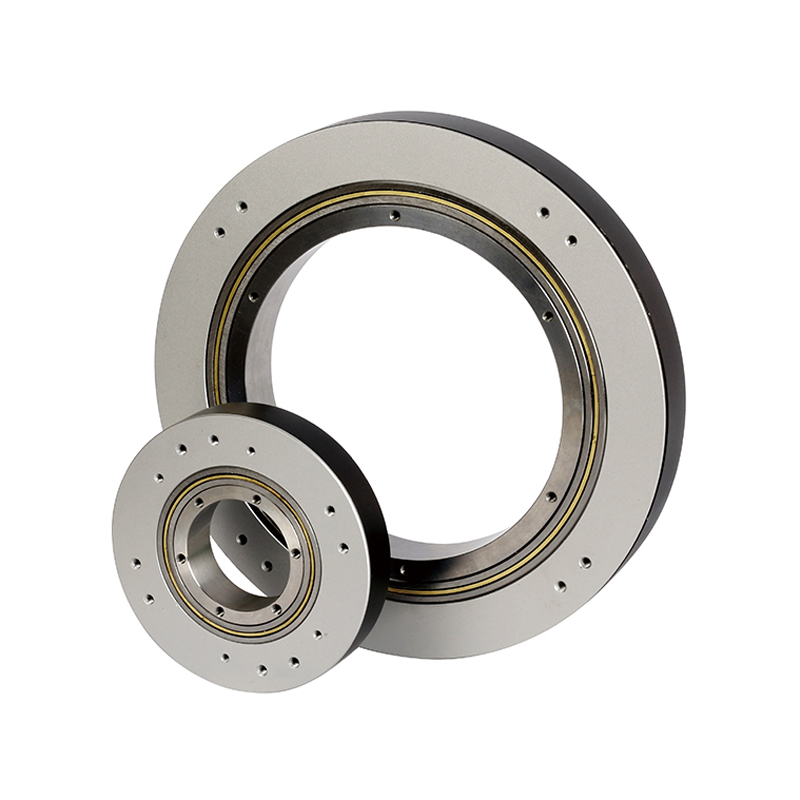

- 控制驱动有刷电机、无刷电机、力矩电机

- 控制模式:位置、速度、转矩

- 集成调试软件,通过串口通信设置调整参数

- 单一直流电源供电

- 保护:过流、过压、欠压、短路、过温、I2T等

输入输出

- ±10V模拟量输入

- 可配置数字量输入

- 可配置数字量输出

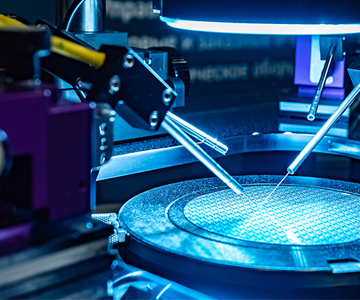

应用案例

主要应用在机器人、AGV小车、贴片机、激光打标机、半导体组装及测试设备、医疗设备、印刷、包装、纺织、激光加工、数控机床、航空、航天等要求高速、高精度、高动态响应、低噪音的中小型自动化设备。