产品描述

高质量材料构成

本炒菜机器人内部线束产品采用优质材料精心打造。导线选用高纯度铜材,确保优异的导电性,保障电力和信号的高效传输。绝缘材料涵盖聚氯乙烯(PVC)和交联聚乙烯(XLPE)等,它们具有出色的绝缘性能和耐腐蚀性,能有效防止短路,保护线束在复杂的机器人内部环境中安全运行。连接器的金属接触件为优质铜合金,塑料外壳坚固且绝缘性良好。保护套管包括波纹管和编织网管,前者可伸缩、柔韧性佳,后者能抗拉伸且有电磁屏蔽功能,而线束固定材料扎带和固定夹强度可靠、使用便捷。

产品参数

| 规格 | 参数 | 规格 | 参数 |

|---|---|---|---|

| 产品名称 | 炒菜机器人内部线束 | 颜色 | 红,黑,黄 |

| 连接器规格 | Aamss-XT60+XT90+PHD2.0 | 线长 | 400mm 可定制 |

| 线材 | UL2464+UL1007 20AWG | 功能 | 耐折弯,抗摇摆 |

| 数量 | 1000PCS,特殊件请咨询客服 | 所有材料均符合 | UL、ROHS、REACH+NP |

| 主要部件 | UL4478超软多芯排线,UL20276高柔屏蔽线 | 样品 | 常规产品均可免费提供样品,详情请联系客服 |

定制流程

咨询客服

了解制定需要

提供您想要的

数量、规格、材质

提供报价协商

下单付款

我们制版设计

您确认方案

确认无误

投入生产

收到货后

确认收货

工艺种类

导线加工工艺

剥皮:精确控制长度和深度去除导线两端绝缘层。

剪断:按要求剪成特定长度,保证切口整齐。

连接器组装工艺

选择匹配的连接器,注意插入方向和深度,以及固定件的紧固程度。

套管安装工艺

安装合适尺寸的保护或电磁屏蔽套管,保障防护和不影响线束性能。

材料

导线材料

绝缘材料

保护套管材料

线束固定材料

品控

炒菜机器人内部线束品控涵盖原材料检验,包括导线、绝缘材料、连接器等质量把关;生产中对导线加工、连接器组装、套管安装、标识环节严格把控;成品要进行电气性能、机械性能和环境适应性测试,确保线束质量可靠。

加工能力

导线加工能力

具备先进设备和熟练人员,能高精度剥皮(误差 ±0.5mm)、精准剪断(公差 ±1mm)、优质锡焊(焊点好,温度和时间可控)。

连接器组装能力

可适配不同规格连接器与导线组装,插入深度偏差 ±0.3mm 内,且组装高效、质量高。

套管安装能力

掌握多种套管安装技术,覆盖率达 95% 以上,还能定制安装增强耐用性。

线束固定能力

能灵活运用多种固定方式,保障固定牢固、间距合理,线束稳定。

附加工序

清洁工序:在加工环节完成后,用静电除尘枪、清洁毛刷等清洁设备去除线束表面碎屑、灰尘,避免杂质进入连接器导致短路或接触不良,降低炒菜机器人运行时的风险。

防护涂层工序:依据线束在机器人内的位置和环境,选择防潮漆、防腐蚀漆等涂料,通过喷涂或浸涂形成 20 - 50μm 厚的均匀涂层,增强防护性能,延长使用寿命且不影响柔韧性和安装。

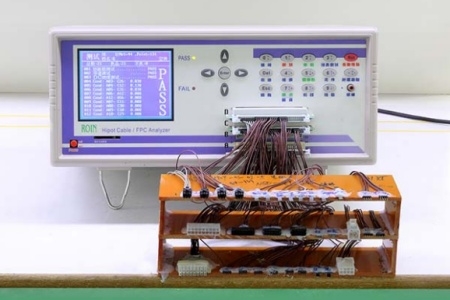

预组装检测工序:完成主要和部分附加工序后,模拟预组装,用导通测试仪、绝缘电阻测试仪等检测电气性能,检查与安装位置的适配性,及时发现并解决问题,减少返工。