Product Description

Harmonic reducer is a new type of reduction device with the characteristics of simple structure, small size, light weight, high efficiency and high precision. It is mainly composed of three basic components: wave generator, flexible gear (flexible wheel) and rigid gear (rigid wheel).

It is widely used in electronics, aerospace, robotics, machine tools, instruments, medical equipment and other industries1. For example, in the field of robotics, harmonic reducer can provide precise deceleration and transmission for the joints of robots, making their movements more flexible and accurate.

Product parameters

| Model | Reduction ratio | Weight | Starting torque | Rated torque | Peak torque | Allowable speed r/min | Moment of inertia | Backlash |

| Grease lubrication | X10-4kgm2 | |||||||

| WXS14 | 30 | 0.51 | 9 | 6.8 | 17 | 3500 | 0.033 | ≤30 |

| 50 | 23 | 9 | 46 | ≤30 | ||||

| 80 | 30 | 14 | 61 | ≤30 | ||||

| 100 | 36 | 14 | 70 | ≤30 |

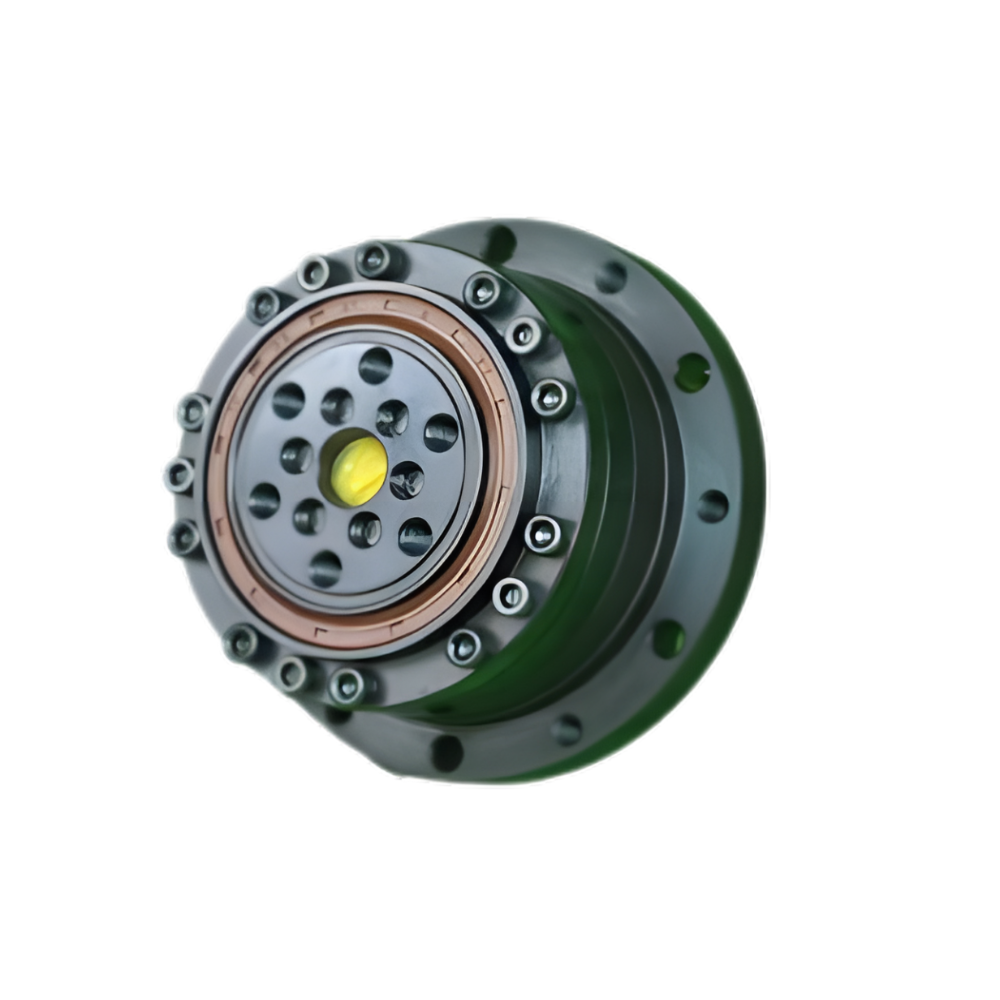

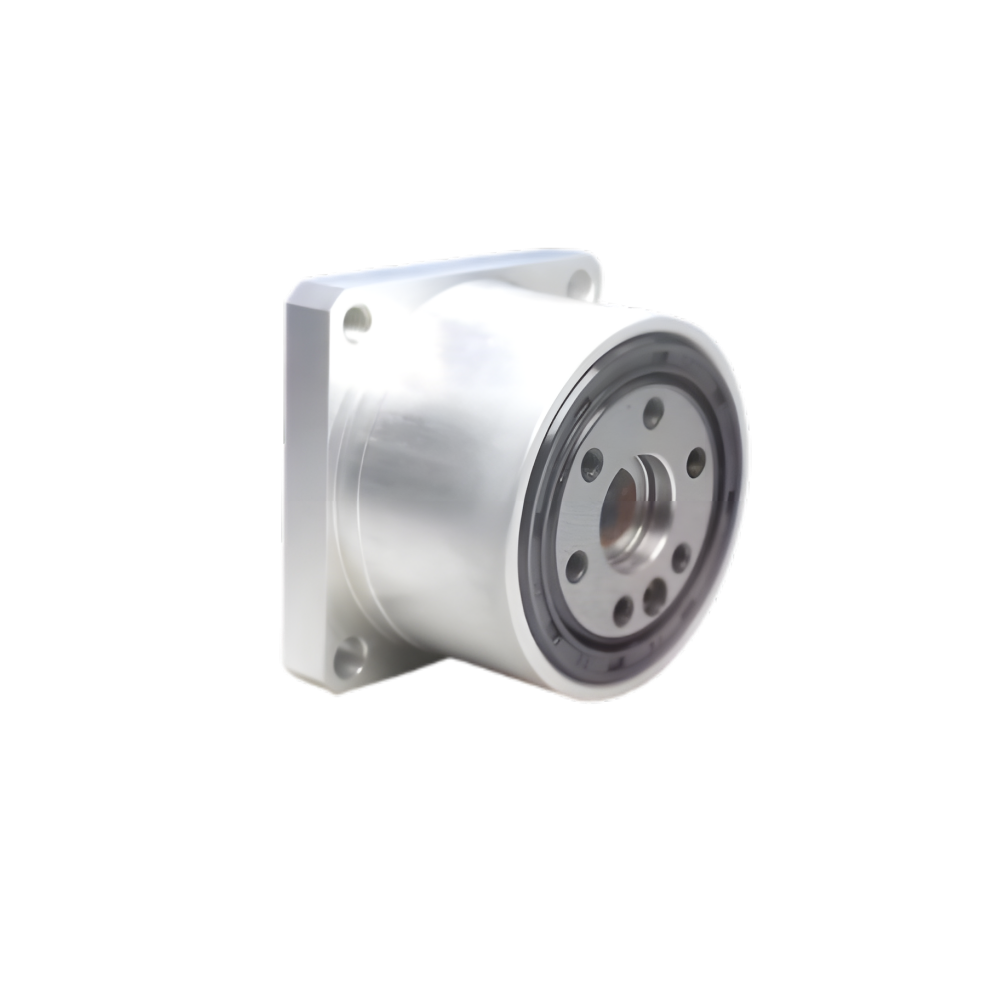

Product Display

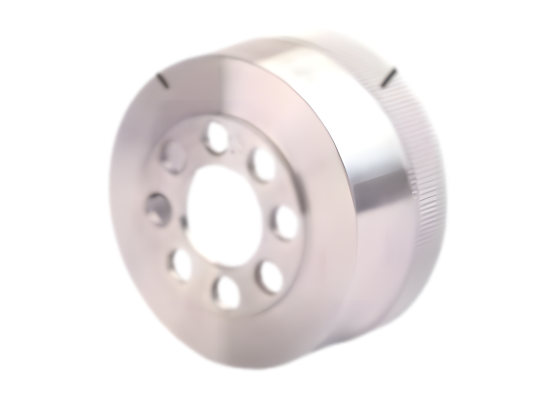

Flexible wheel: installed on the wave generator, it plays the role of supporting and positioning the wave generator, ensuring that the wave generator can accurately and stably drive the flexible gear to deform. The flexible bearing needs to have good wear resistance and impact resistance to meet the needs of high-speed and high-precision transmission.

Rigid wheel: special steel is selected, which has high strength and high wear resistance; low temperature heating treatment after tempering reduces brittleness and internal stress.

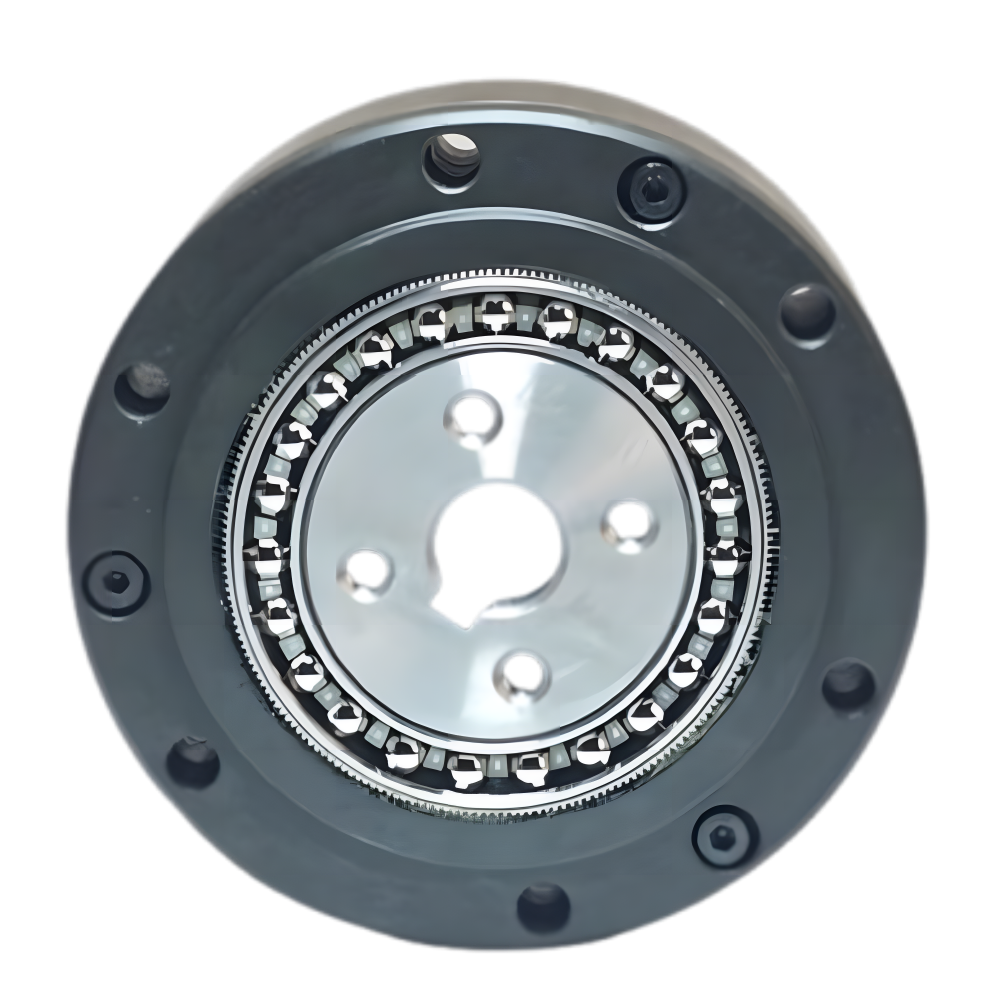

The number of teeth of the gear with an inner ring is slightly larger than that of the flexible gear. Rigid gears are usually used as fixed parts in harmonic reducers, meshing with the teeth of the flexible gear to transmit motion and power. The rigid wheel is generally fixed on the outer shell to support and transmit power.

The built-in cylindrical rollers are arranged crosswise, with high rotation accuracy and high load-bearing capacity.

Installed on the wave generator, it plays the role of supporting and positioning the wave generator, ensuring that the wave generator can accurately and stably drive the flexible gear to deform. The flexible bearing needs to have good wear resistance and impact resistance to meet the needs of high-speed and high-precision transmission.

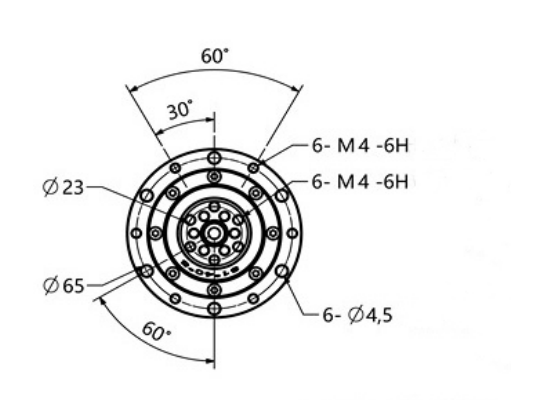

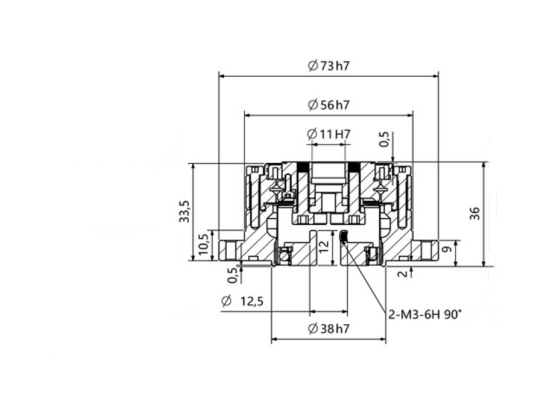

Size & Interface

Application Cases

The harmonic reducer has the characteristics of high precision, large transmission ratio, small size and light weight, which makes the joint movement of the robot more flexible and accurate, and improves the operation accuracy and work efficiency of the robot. For example, most of the joints of welding robots, handling robots, assembly robots, etc. use harmonic reducers.