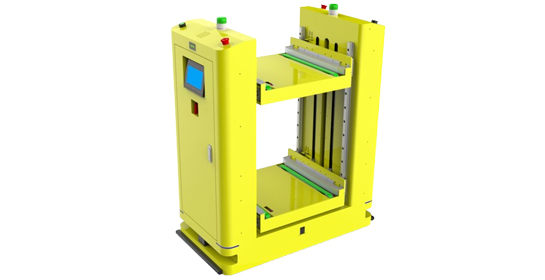

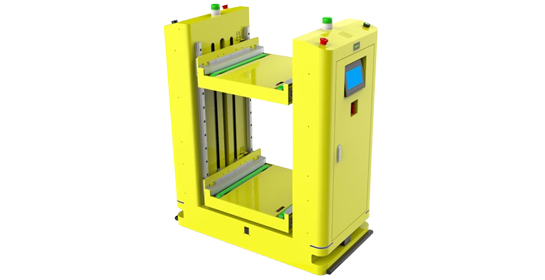

产品描述

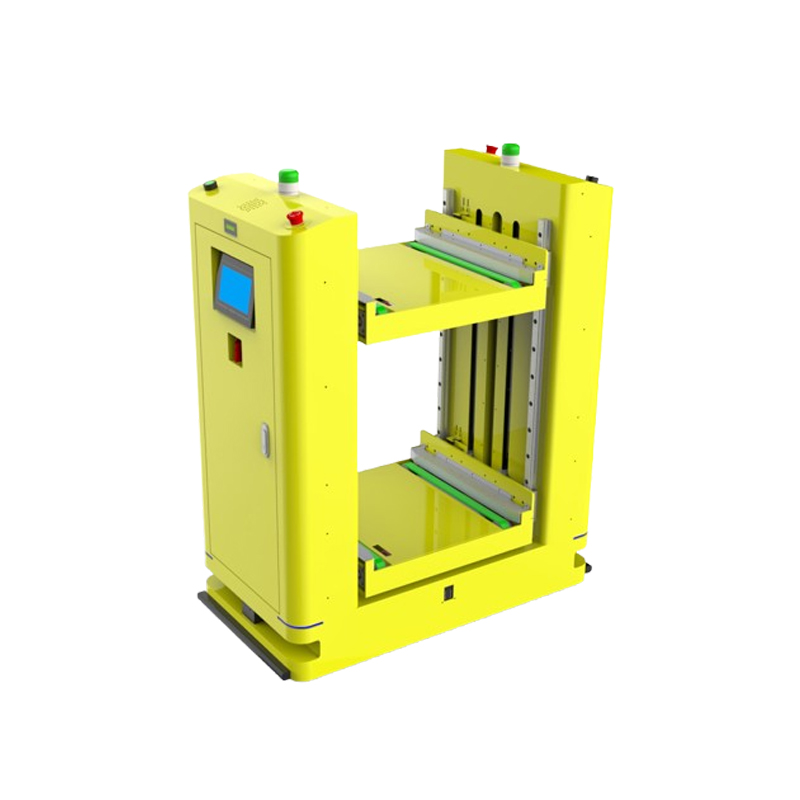

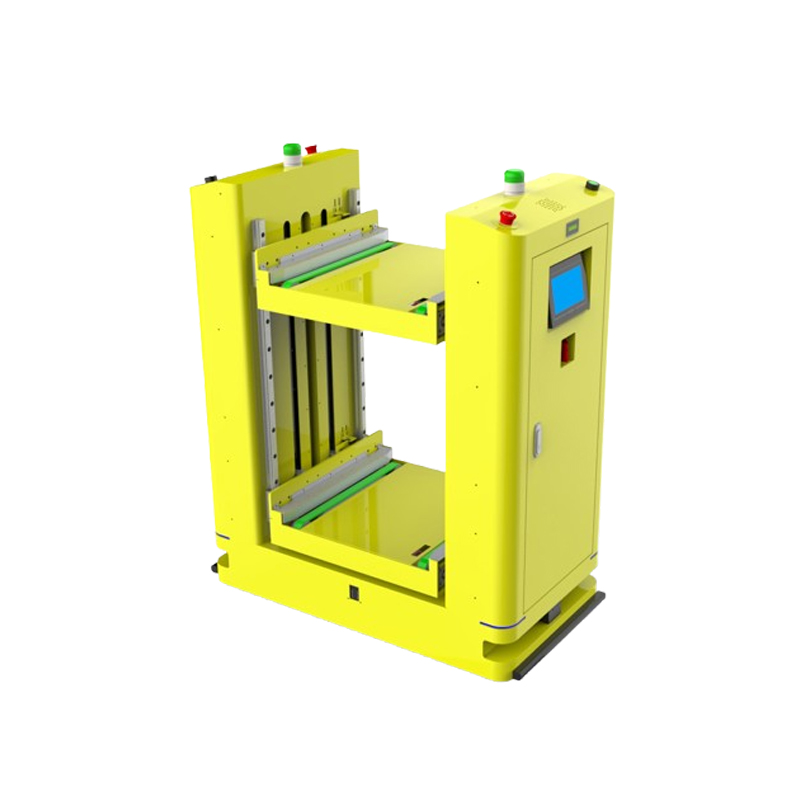

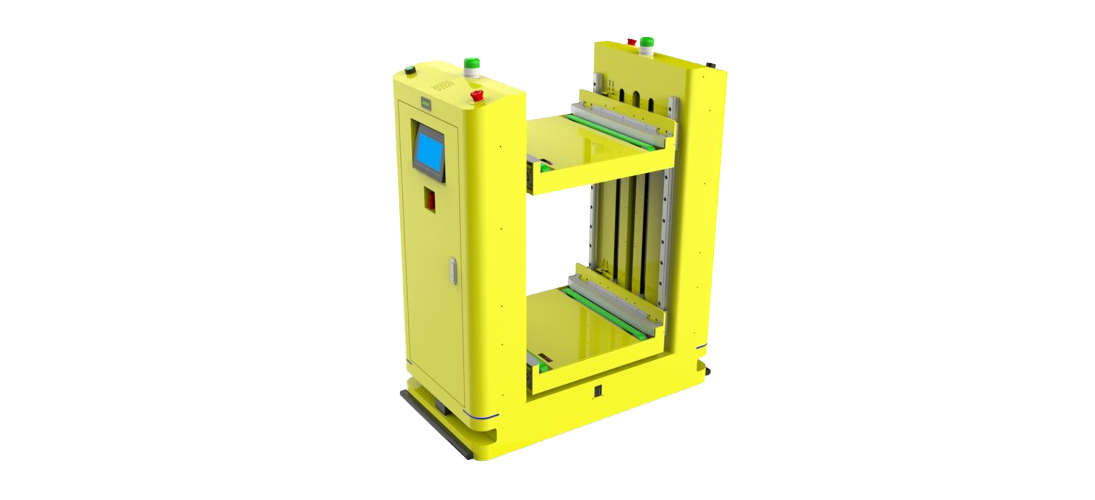

自动对接输送式 AGV 是现代物流与生产自动化领域的卓越创新。它就像一位精准高效的智能搬运大师,能够自动识别预设路线,沿着规划好的路径稳定行驶。其对接输送功能更是一大亮点,可与生产线上的各个环节或者仓储系统无缝衔接,无论是物料的接收还是产品的转运,都能轻松应对。在工作过程中,它以高度的准确性和稳定性确保物品安全运输,有效避免了人工搬运可能出现的失误和损耗。而且,这种 AGV 还具有出色的负载能力,可承载不同重量和规格的货物,极大地提高了整个物流和生产流程的自动化水平和运作效率,是企业迈向智能化生产与物流管理的得力助手。

产品特性

SMT同步带双层对接式,可前进、后退、90°/180°/360°旋转、圆弧转弯、加速、减速、分岔转弯、定时停止、换向运行等多功能行驶;

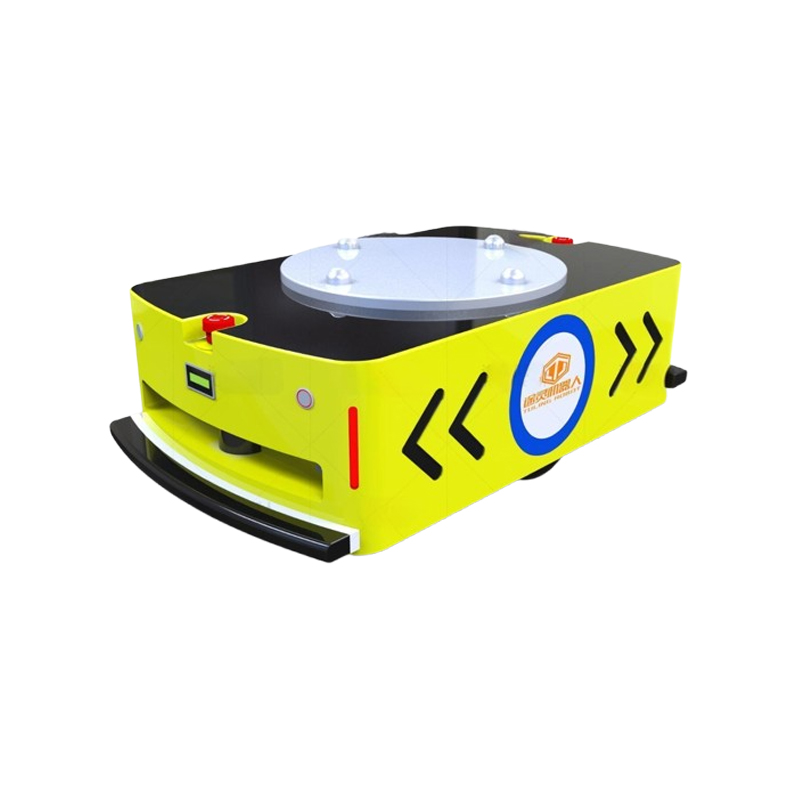

多传感器融合导航安全可靠、柔性高效、无需人工干预实现全自动化、自动搬运降低人工劳动强度、智能调度无缝对接MES/WMS/ERP系统、提升物流效率、快速灵活的适应不同复杂场景,高效完成物流的自动运输工作。

AGV的顶端可以搭载滚筒、输送带、同步带等输送平台装置;可以自动对接输送线或生产线,自动将AGV上运载的物料传输至输送线上,或将输送线上的物料自动回收至AGV的输送平台上,然后由AGV将物料自动对接输送到下一个对接输送线上,完成产线的自动上料、下料工作。

产品参数

| 性能参数 | 说明 |

|---|---|

| 产品型号 | TL-SMT-1255SX- 002 |

| 外形尺寸 | 标准L1075mm*W550mm*H1255mm/离地对接高度300/1000mm(或定制) |

| 导航类型 | 磁条导航 |

| 驱动形式 | 差速驱动 |

| 行走方式 | 前进、后退、旋转、分岔转弯、定时停止、换向运行等多功能行驶 |

| 行走速度 | 0~40m/min(或定制) |

| 额定负载 | 100KG(或定制) |

| 爬坡能力 | ≤2度 |

| 转弯半径 | 500mm或原地90°/180°/360°旋转 |

| 停止精度 | ±10mm |

| 导航精度 | ±10mm |

| 续航时间 | 8-12H(或定制) |

| 充电方式 | 手动充电/自动充电(可选配) |

| 人机交互 | 4.3寸触摸屏 |

| 报警形式 | 声光报警 |

| 通信网络 | WIFI网络/射频网络 |

| 动力电池 | 50Ah磷酸铁锂电池 |

| 安全防护 | 障碍物传感器+接触式保险杠+急停按钮 |

| 设计寿命 | >80000H |

注:此款AGV小车为非标定制产品,价格需根据定制尺寸联系商家进行咨询

客户案例

3C电子行业-AGV自动充电案例

激光导航-AGV叉车项目

山东青岛海尔工厂AGV项目

服务

专业化团队

途灵机器人公司研发团队保证能够研发出直接面向企业实际需求的产品,参与研发的团队成员有AGV行业专业家、技术专家、物流规划专家、高级项目管理专家、高级售后人员。

强大的实施能力

我们有资深的AGV应用行业实施经验,有能力和实力对广大用户企业物流自动化需求提供全面的解决方案。

自主的知识产权

所有AGV小车的控制模块(软、硬件)、机械结构,机构模块组件均由途灵机器人公司自主研发,并申请了专利保护。

性价比高

产品的性能达到或超过进口相同档次的产品,价格仅仅是进口产品的三分之一。

质量可靠,稳定性好

产品生产出厂前,都会经过严格的EMC、温度、湿度、震动、寿命、稳定性等方面检验。

实施周期短

签订合同后,在短期内就可以交付给客户使用。

售后有保障

我们有强大的售后技术团队,售后有任何问题,公司24小时随时提供专人售后服务。

包装

我们深知商品在运输过程中的安全至关重要,因此在包装上投入了大量的精力。我们的专业包装团队会根据商品的特性,选用最合适的包装材料,使产品在运输中的损害降到最低。我们的产品包装,是安全与品质的坚固堡垒,为你的购买体验保驾护航。

运输

我们与全球知名的国际快递公司合作。这些快递公司拥有广泛的全球网络和高效的物流系统,确保您的跨境包裹能够快速、安全地送达。