产品描述

编码器K58-4C系列,有磁电和光电两种。

具有抗干扰性能强,设计坚固,安装方便等特点。

抗污染能力强,全封闭式模块,可方便地安装到未受保护的表面。

产品参数

机械参数

最大转速(r/min) | 启动力矩(25℃) (N. M) | 轴向最大负载(N) | 转动惯量 (kgm2) | 重量 | |

|---|---|---|---|---|---|

| 径向 | 轴向 | ||||

| 6000 | 6*10-³ | 40 | 30 | 8.5*10-6 | ≤0.36 |

电气参数

| 输出形式 | 电源电压 DC(V) | 消耗电流 (mA) | 输出电压(V) | 上升时间 (ns) | 下降时间 (ns) | 响应频率 (kHz) | |

|---|---|---|---|---|---|---|---|

| VH | VL | ||||||

| E(电压输出) | 5±0.25 | ≤80 | >3.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | ≤120 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 | |

| 10-30 | |||||||

| 12 | |||||||

| F(互补输出) | 5±0.25 | ≤80 | >3.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | ≤120 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 | |

| 10-30 | |||||||

| 12 | |||||||

| C(集电极 开路输出) | 5±0.25 | ≤60 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | |||||||

| 10-30 | |||||||

| 12 | |||||||

| L(长线驱动输出) | 5±0.25 | ≤100 | >3.5 | ≤0.7 | ≤200 | ≤200 | 0-300 |

| A(宽压长线 驱动输出) | 8-26 | ≤60 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 10-30 | |||||||

| 12 | |||||||

接线说明

| 电缆线颜色 | 红 | 黑 | 绿 | 棕 | 白 | 灰 | 黄 | 橙 | 屏蔽 |

|---|---|---|---|---|---|---|---|---|---|

| E(电压输出) | Vcc | 0V | A | B | Z | G | |||

| F(互补输出) | Vcc | 0V | A | B | Z | G | |||

| C(开路输出) | Vcc | 0V | A | B | Z | G | |||

| L、A(驱动输出) | Vcc | 0V | A | A/ | B | B/ | Z | Z/ | G |

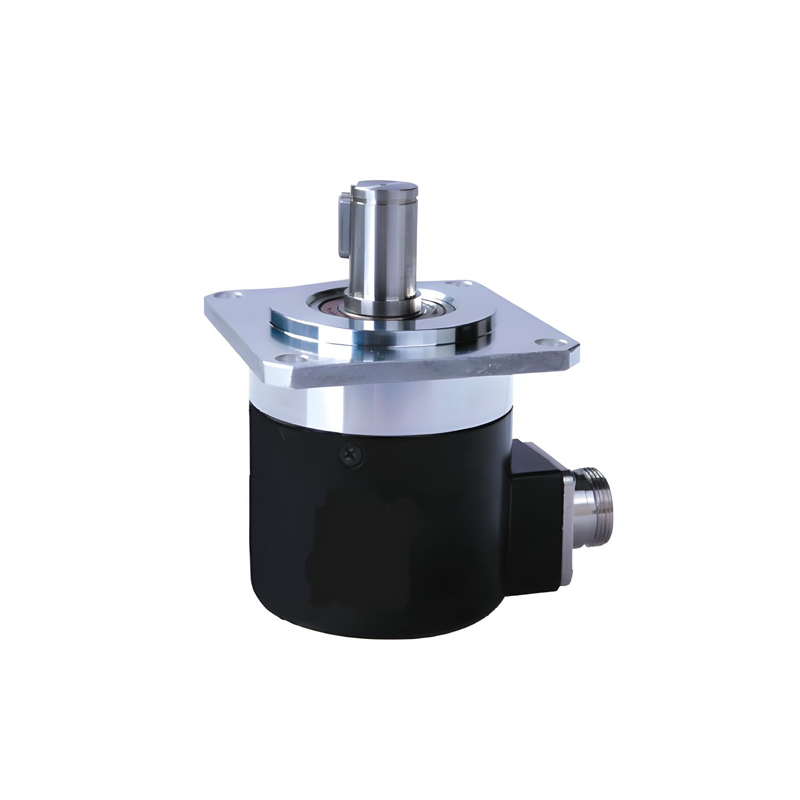

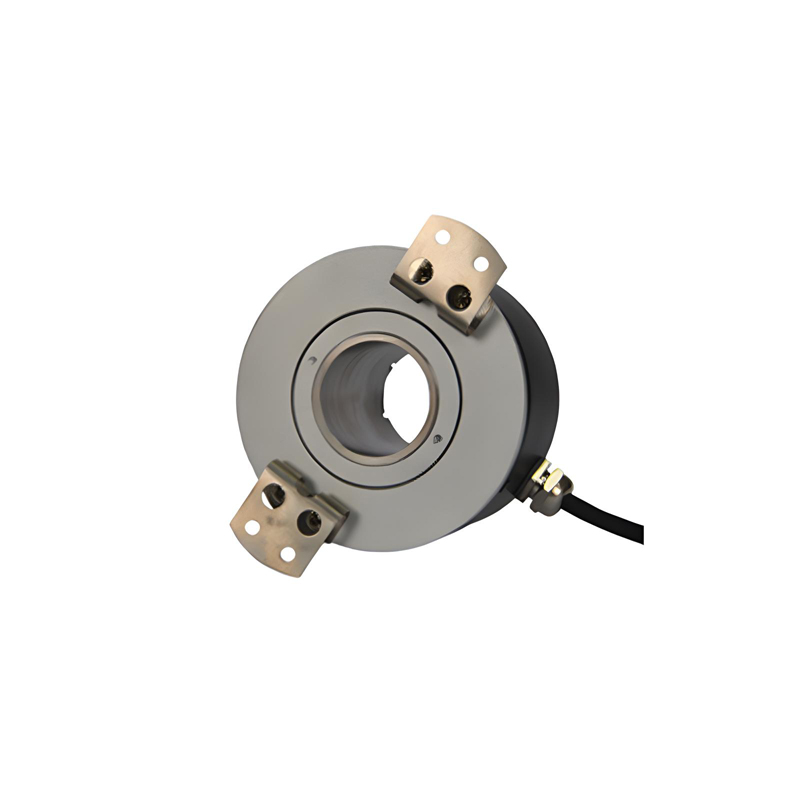

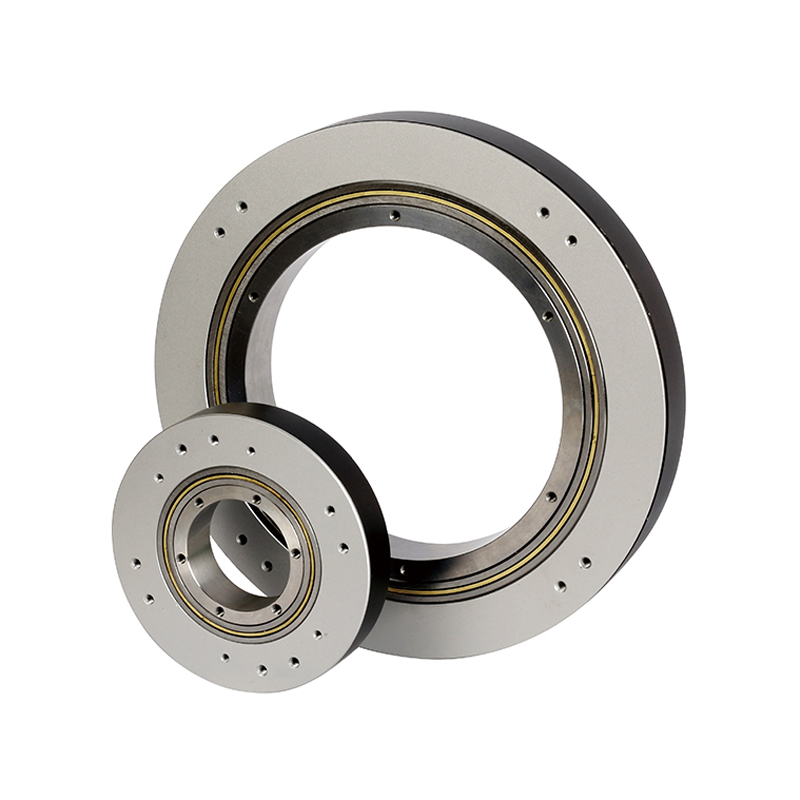

产品展示

- 脉冲信号输出:增量电机编码器转轴旋转时会输出周期性的脉冲信号。这些脉冲的频率与电机的转速成正比,通过对脉冲的计数和测量,可以获取电机的转速信息。例如,在数控机床中,可根据编码器输出的脉冲频率实时调整刀具的进给速度。

- 相对测量:增量编码器测量的是相对位置变化,它记录的是电机从某一参考点开始的位移增量。这意味着如果系统断电或重新启动,编码器的位置信息会丢失,需要重新寻找参考点进行位置校准2。不过,在一些对绝对位置要求不高,或者可以方便地进行回零操作的应用场景中,增量编码器的相对测量特性能够满足需求,并且具有成本较低、测量精度较高的优势。

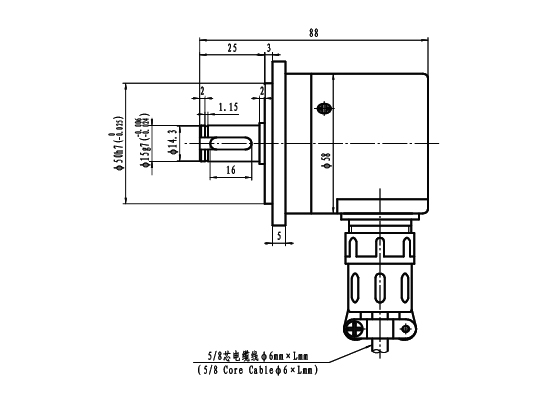

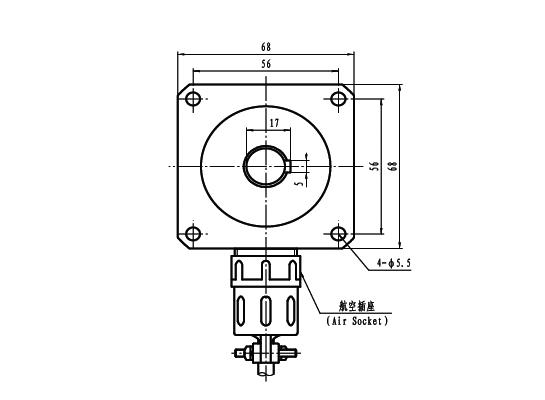

尺寸和接口

应用案例

在现代化工业生产的宏大场景中,增量电机编码器有着广泛应用。比如在数控机床领域,它安装在电机轴上,为刀具的精确移动和工作台的精准走位提供脉冲信号,保障复杂零件加工精度达微米级;在自动化物流输送系统中,位于传送带电机处的增量电机编码器能精准控制速度和启停位置,使包裹准确无误地流转于存储、分拣和运输环节;在工业机器人进行汽车零部件装配时,安装于关节电机轴的编码器实时反馈信息,精确指挥机器人手臂的动作,实现毫米级的装配精度,确保生产质量和效率。

服务

即使在极端苛刻的条件下,顺为产品也能可靠完成任务,比无论是工程厂、海上、石油、航天、水利等领域。长期的温度可靠性试验发现产产品方案弱点,因此能够及早进行修正。 然而,质量不仅仅只涉及客观的产品特性,更会影响我们全体员工的思维和行为方式。 确保高质量优良传统: 我司已经过质量体系认证。