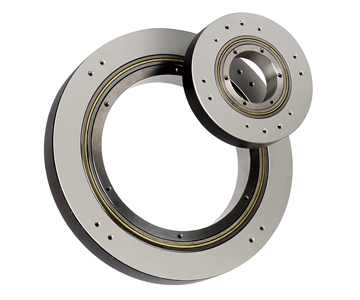

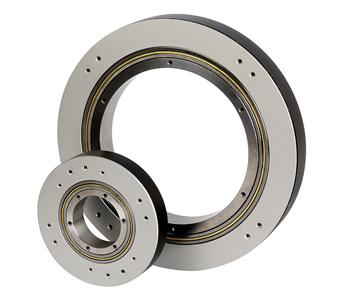

Product Description

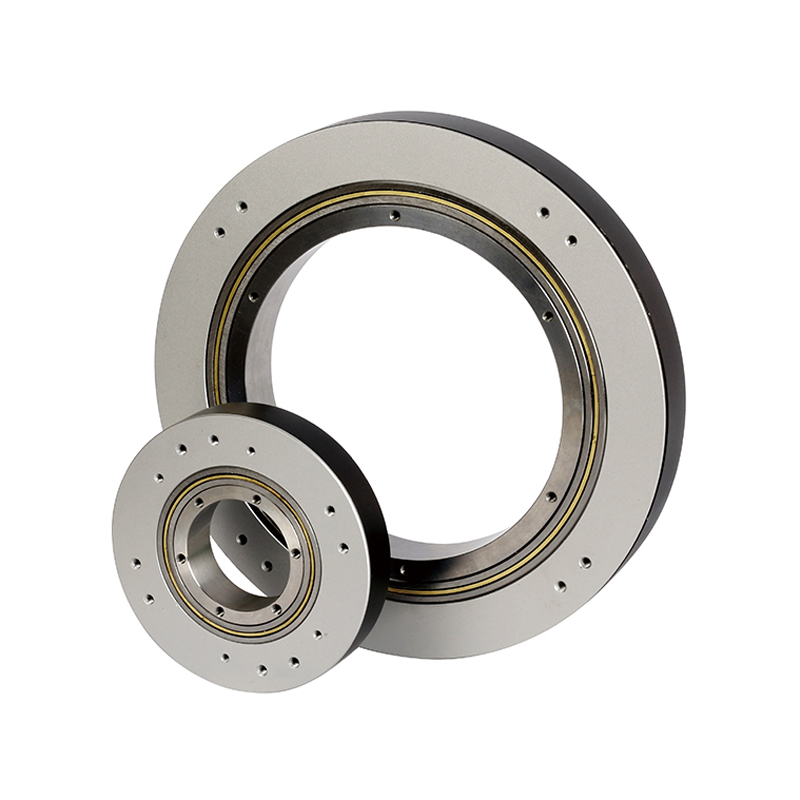

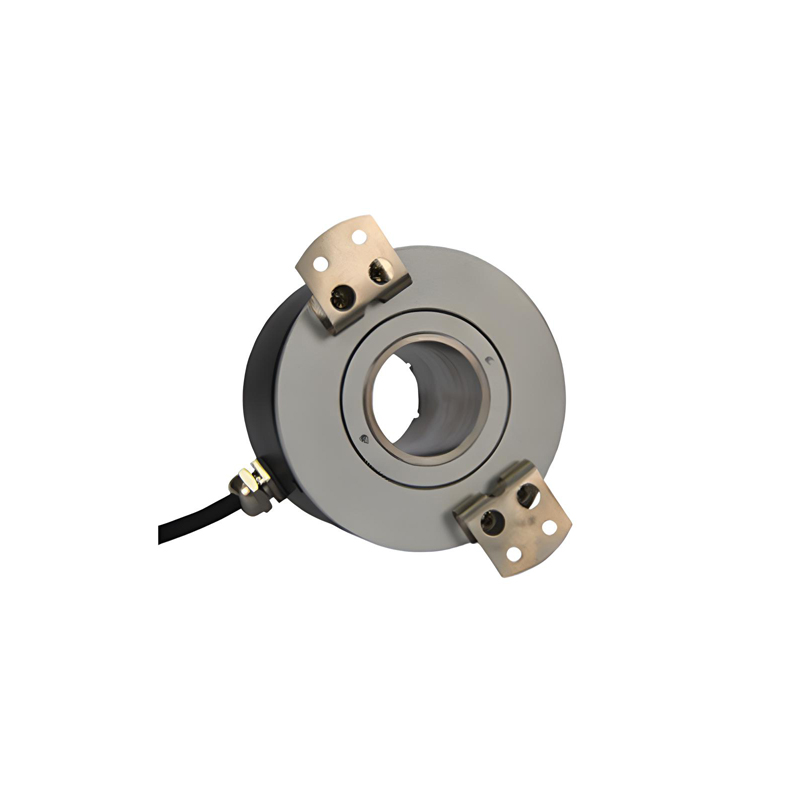

T series ultra-thin photoelectric encoder

High integration, can be highly integrated with customer products

Split installation, simple and convenient

Minimum thickness is only 10mm, more lightweight design

Product parameters

Electrical parameters

| Single-turn resolution | 8-20 digits |

|---|---|

| Multi-turn digits | Any |

| Maximum accuracy | ±10 |

| Supply voltage | 5v 10-30v |

| No-load current consumption | 300mA/5V |

| Battery voltage range (only for multi-turn) | No battery |

| Absolute value communication protocol | SSI RS485/422 BISS |

| Absolute value communication electrical standard | TIA/EIA-422-B |

| Absolute value communication maximum transmission rate | 2MHz(SSI) |

| Incremental pulses/turn (square wave number/turn) | / |

| Assembly aids | No |

| Anti-electromagnetic interference | EN 61000-6-2 |

| Electromagnetic emission | EN 61000-6-3 |

Mechanical parameters

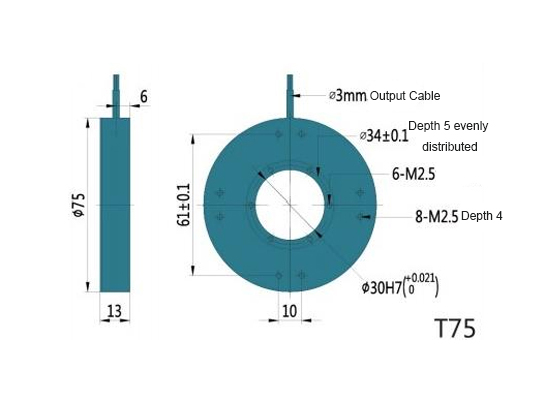

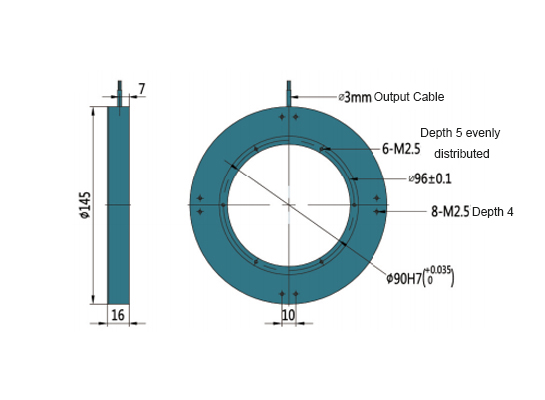

| Dimensions | See dimensional drawing |

|---|---|

| Operating speed | <3000r/min |

| Axial movement allowed | ± 0.1 mm |

| Radial movement allowed | ± 0.1 mm |

| Operating temperature range | ‘-40~+85°C(Can be customized) |

| Maximum relative humidity allowed | <98% |

| Protection level | IP54 |

| Vibration and shock | GJB |

| Material | Body / Stainless steel Shaft / Stainless steel |

Wiring Instructions

| Color Protocol | Red | Black | Blue | Green | Yellow | White | Shield |

|---|---|---|---|---|---|---|---|

| RS485/ Modbus | VCC | GND | A | B | G | ||

| RS422 | VCC | GND | TXD+ | TXD- | RXD+ | RXD- | G |

| SSI | VCC | GND | DATA+ | DATA- | CLOCK+ | CLOCK- | G |

| CAN | VCC | GND | CANH | CANL | G | ||

| BISS | VCC | GND | DATA+ | DATA- | CLOCK+ | CLOCK- | G |

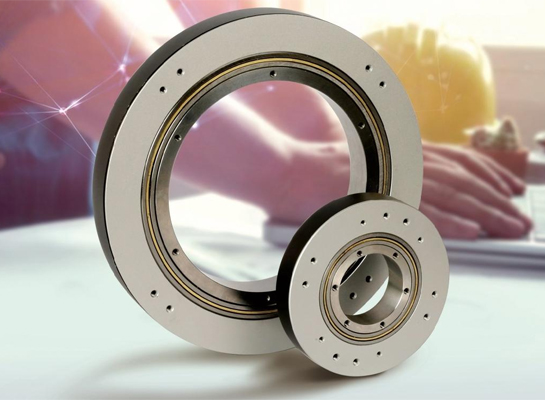

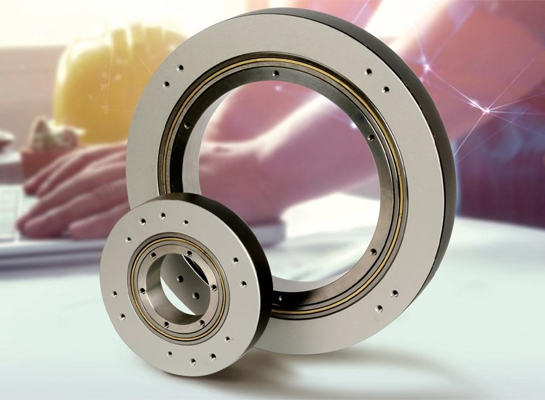

Product Display

High integration

This encoder has high integration. It integrates multiple complex functional modules such as photoelectric conversion and signal processing in a compact package, greatly reducing the number of external connections and components. It is like a fully functional microchip, effectively improving the stability and reliability of the system. It may also integrate additional functions such as temperature compensation and fault diagnosis.

Impact resistance

The photoelectric encoder has the characteristics of impact resistance. Its key components such as code disk and housing are made of high-strength and high-toughness materials. These materials can withstand a large degree of external force impact without damage or deformation. In addition, the perfect protection design, including sealing and buffering structure, can effectively resist the damage of external impact to internal optical components and circuit modules.

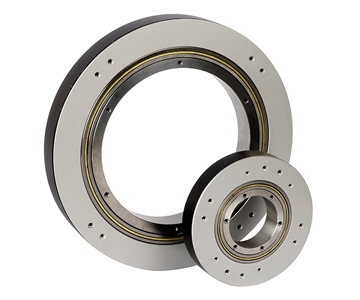

Size & Interface

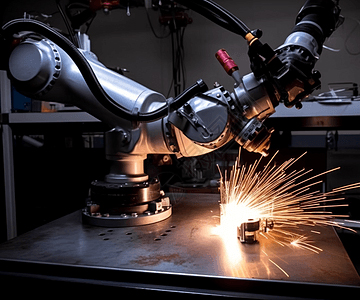

Application Cases

- In industrial robotic arms, ultra-thin photoelectric encoders are used to precisely control the joint motion of the robotic arm to achieve high-precision grasping and operation.

- In 3D printers, it can accurately monitor the position of the print head to ensure the accuracy of the printed model.

- In precision CNC machine tools, ultra-thin photoelectric encoders assist in measuring the displacement of the tool to improve the precision of the processed parts.

- In robotic automated guided vehicles (AGVs), it is used to determine the rotation angle of the wheels and the driving position of the vehicle to achieve precise navigation.