Product Description

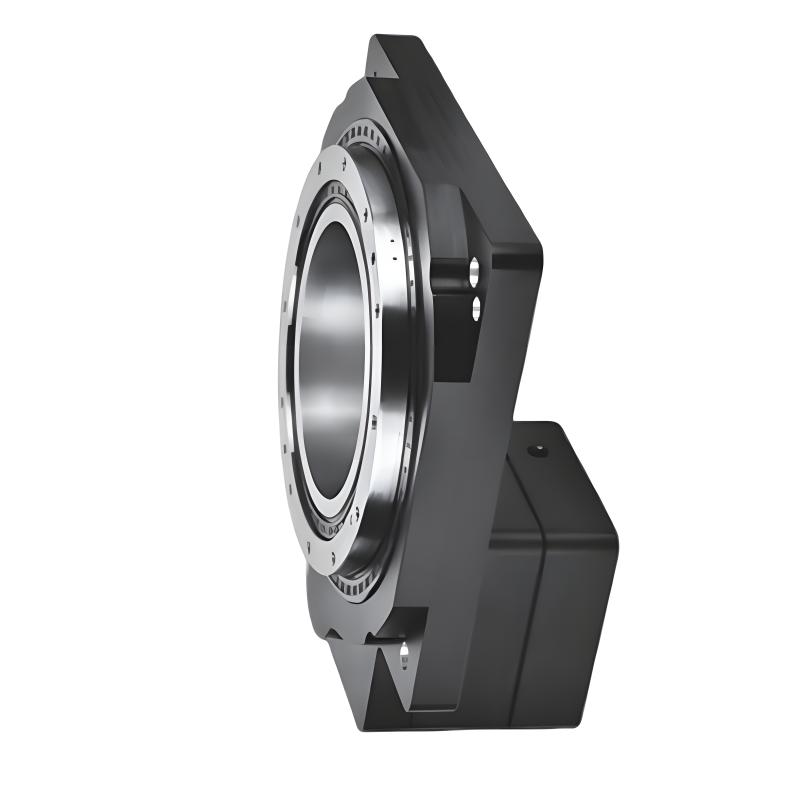

The turntable is hollow design, the servo motor is connected on the side, this unique structure is convenient for the installation of gas pipes and wires in the mold, making the wiring of the equipment more concise and orderly, avoiding the problem of line winding, in the automatic production line and other high wiring requirements of the occasion has obvious advantages of high-precision gear transmission and precision bearing support, as well as advanced control system coordination. The platform can achieve extremely high positioning accuracy and repeated positioning accuracy, which can meet a variety of application scenarios with demanding accuracy requirements.

Product parameters

| Model | KTN60-05K | KTN60-10K | KTN85-05K | KTN85-10K | KTN85-18K | KTN110-50K | KTN130-10k | KTN170-10k | |

| Motor type | Each brand 50-100W servo motor (can add planetary reducer) | Each brand 50-100W servo motor | Each brand 200-400W servo motor | Each brand 200-400W servo motor (can add planetary reducer) | Each brand 100W servo motor | Each brand 200-400W servo motor | Each brand 200-400W servo motor | Each brand 750W servo motor (can add planetary reducer) | |

| Rotary platform bearing | N.m | Cross roller bearing | |||||||

| Allowable torque | rpm | 5.2 | 5.2 | 8 | 8 | 8 | 20 | 32 | 48 |

| Allowable speed | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | 200(Disk surface) | |

| Reduction ratio | N | 1:05 | 1:10 | 1:05 | 1:10 | 1:18 | 1:50 | 1:10 | 1:10 |

| Axial load is allowed | N.m | 250 | 250 | 500 | 500 | 500 | 1000 | 2000 | 3000 |

| Allowable inertia moment load | arcsec | 5 | 5 | 10 | 10 | 10 | 25 | 50 | 68 |

| Positioning accuracy | arcsec | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 |

| Repeated positioning accuracy | mm | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 |

| Application of platform parallelism | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Rotating platform concentricity | IP | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Class of protection | H | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Precision life | kg | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 |

| Weight | 1.2 | 1.2 | 1.8 | 1.8 | 1.8 | 2.6 | 4 | 10 | |

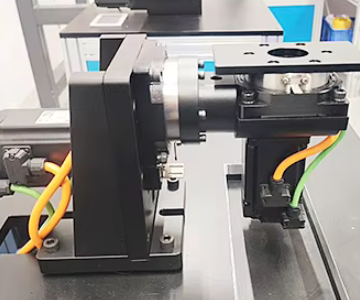

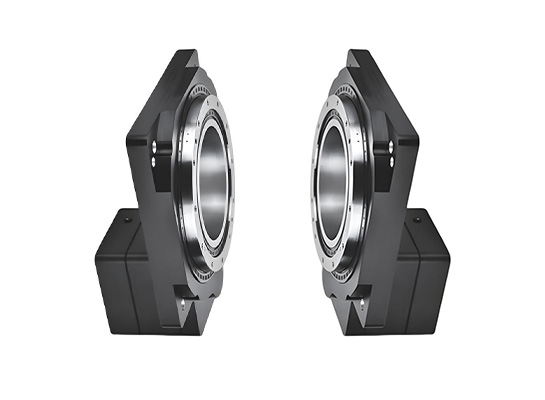

Product Display

Through the precise design of gears and clearance adjustment mechanisms, the hollow rotary platform can achieve extremely high repeatability positioning accuracy, which can meet the needs of industrial production and scientific research with stringent requirements on positioning accuracy, such as precision assembly, testing and other fields.

The application of precision cross roller bearings gives the platform excellent rigidity, enabling it to maintain stable rotation performance when subjected to heavy loads, and is not prone to deformation and vibration, making it suitable for heavy-load conditions.

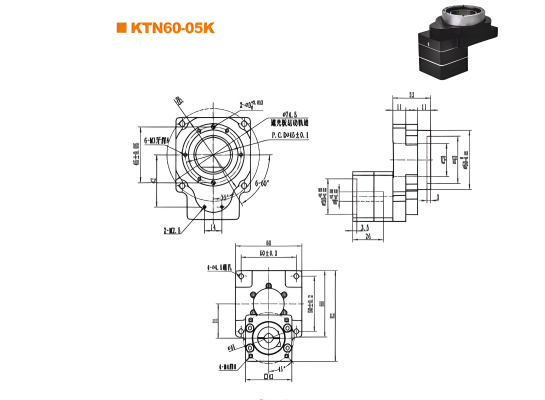

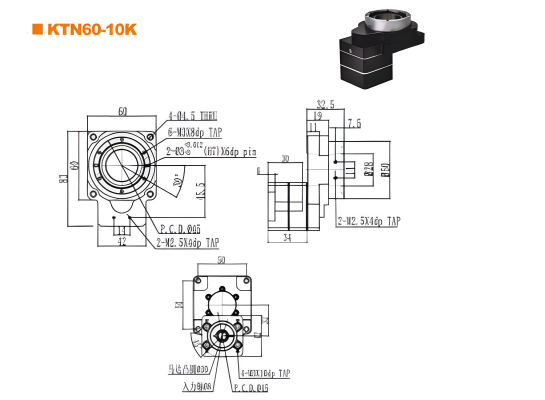

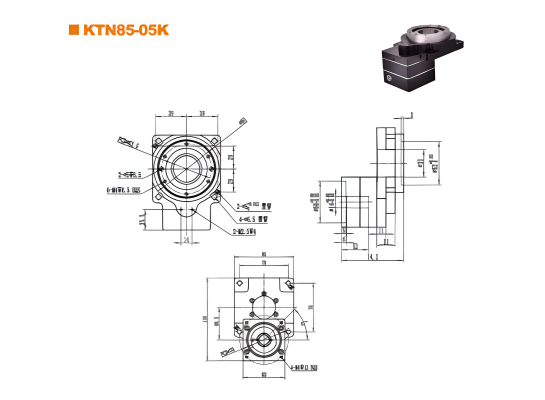

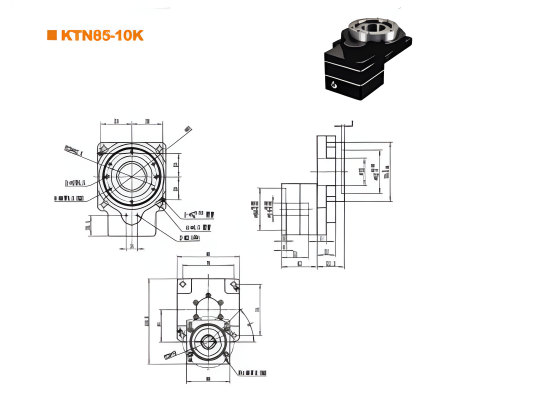

Size & Interface

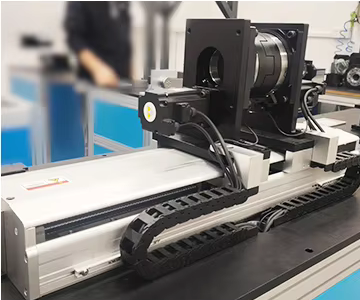

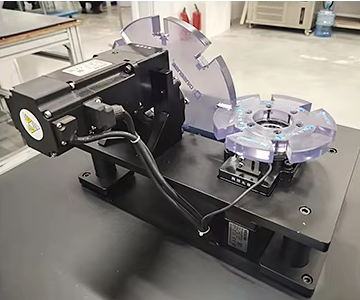

Application Cases

· Automatic production line: suitable for material sorting, transmission, assembly, testing and other links of various automatic production lines, which can realize accurate rotation positioning of materials and improve production efficiency and product quality, such as automatic packaging production line and electronic component production line.

· Robot arm joint: As a joint component of the robot arm, it can realize flexible rotation and accurate positioning of the robot arm, complete various actions such as grasping, handling and assembly, and is widely used in automated production lines, logistics warehousing and other fields.

· The fourth machining axis of the machine tool: adding a rotating axis to the machine tool expands the processing capacity of the machine tool, and can be used to process parts with complex shapes, such as precision parts such as impellers and blades in the aerospace field.