Product Description

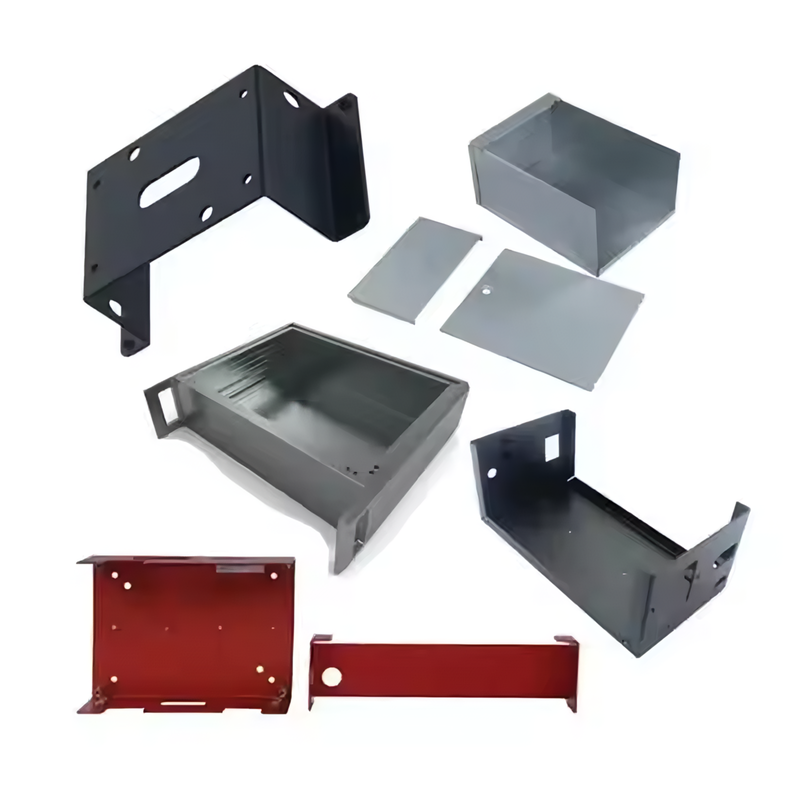

Custom various sheet metal fabrication provides tailored solutions for creating and shaping metal sheet components to meet specific customer requirements. Our services include cutting, bending, punching, stamping, and welding, utilizing high-quality materials such as stainless steel, steel, aluminum, or other specialty metals. With a team of skilled professionals, we deliver precision-crafted parts for a wide range of applications, including automotive, electronics, construction, and more. Whether for small-batch or high-volume production, we ensure accuracy, efficiency, and reliability in every step of the process, guaranteeing superior quality and exceptional value for our clients

Product parameters

| Service | Professional Custom Sheet Metal Fabrication |

| Material | Stainless Steel, Aluminum, Copper, Brass, Bronze, Iron etc. |

| Size or Shape | According to customer drawing |

| Surface Treatment | Spraying plastics,Electroplating oxidation,Powder coating,Nickel plating,Chrome plating,Electroplating etc |

| Accuracy | Laser Cutting;+/-0.1mm CNC Bending:+/-0.1mmSurface Roughness:Ra 3.2 Welding:+/-O.2mm |

| Package | Outside carton box,or customized |

| Delivery Time | 5-30 Days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Tool Storage Cabinets

Sheet metal is used in the production of tool storage cabinets and equipment that need to withstand heavy usage in factories or work environments with challenging conditions, such as high dust or humidity. Sheet metal provides strength, durability, and impact resistance, making the cabinets long-lasting and capable of protecting tools from damage

Structural Supports

In construction, cast iron stainless steel is used for structural supports such as beams, columns, and brackets because of its high tensile strength and durability. This material provides reliable support for buildings and infrastructure, especially in environments subject to heavy loads and corrosive conditions

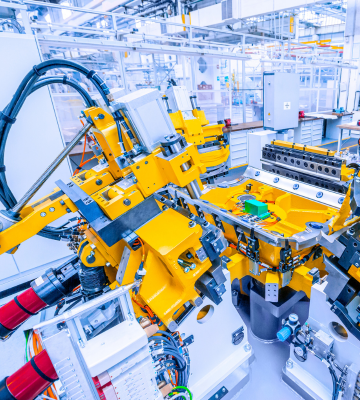

Industrial Machinery

Sheet metal is a critical material in the construction of industrial machinery, including components such as housings, panels, and structural supports. Its strength and ability to be precisely cut, bent, and welded allow manufacturers to produce robust machinery capable of handling heavy loads and extreme conditions

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in aluminum sheet metal fabrication makes sure the products meet the required standards and customer needs. It includes checking the material for defects, measuring dimensions accurately, and ensuring the surface finish is even. Welds are checked for strength, and parts are tested to make sure they fit and work properly. During production, the process is monitored, and a final inspection is done before shipping. Customer feedback helps improve quality over time.

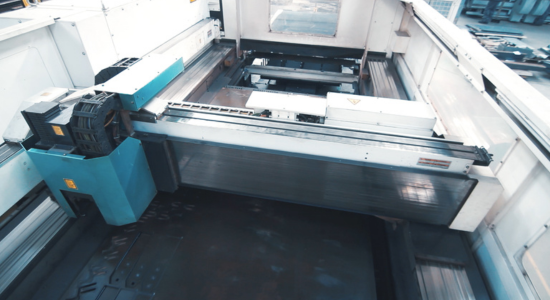

Processing capability

The processing capability of aluminum sheet metal fabrication includes several methods to create custom parts. These include cutting, bending, punching, stamping, welding, and assembly. With tools like CNC machines, laser cutters, and presses, parts are made accurately and efficiently. Aluminum sheets can be shaped to fit specific designs, whether for small or large production runs. Additional processes like surface finishing, coating, and cleaning are also available to ensure high-quality, durable products for various industries

Additional processes

Additional processes in aluminum sheet metal fabrication include surface finishing, coating, cleaning, and welding. After shaping the metal, the surface can be treated to make it smoother or more durable, like using anodizing or powder coating. Cleaning removes rough edges to ensure safety and better fit. Parts can also be welded together to create larger pieces. These extra steps help improve the quality, strength, and look of the final product, making it suitable for different uses.