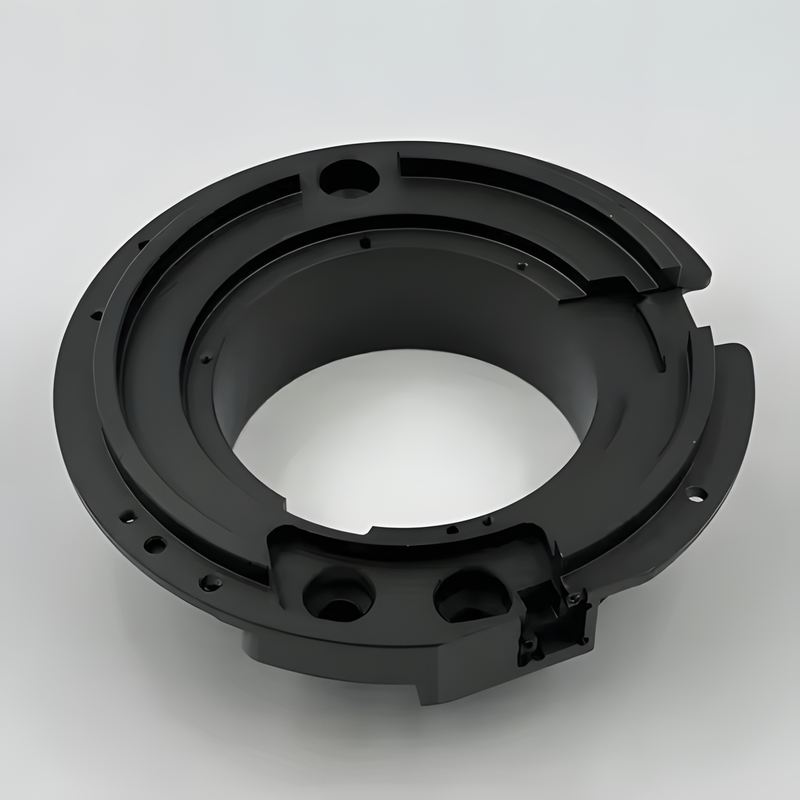

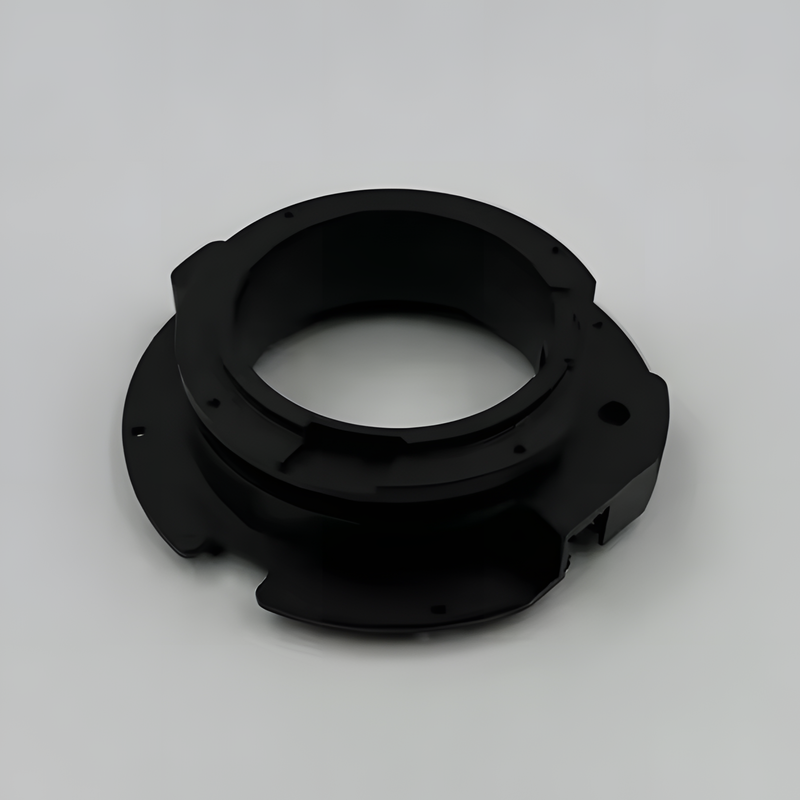

Product Description

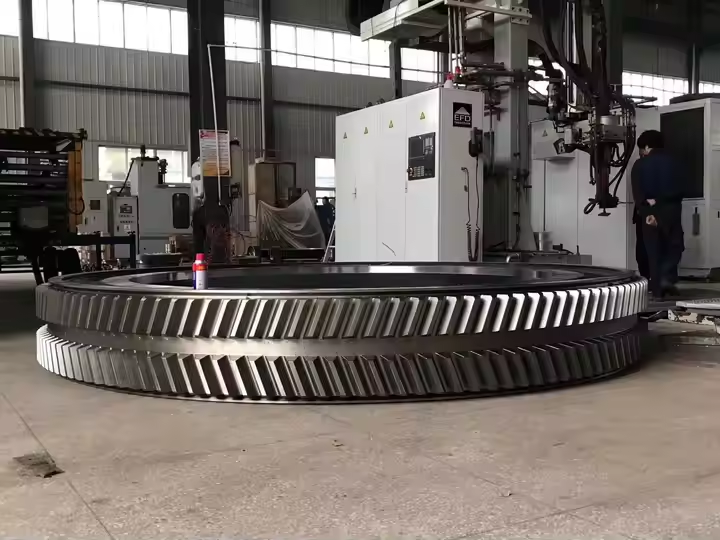

refer to custom-made components produced using CNC (Computer Numerical Control) machining technology. This process involves precise cutting, milling, drilling, turning, and grinding of metal or plastic materials based on digital designs. CNC processing ensures high accuracy and consistency, making it ideal for manufacturing spare parts that fit specific machinery or equipment. These parts are typically used in industries like automotive, aerospace, electronics, and manufacturing to replace worn-out or damaged components, ensuring the continued functionality of machines and systems. CNC processing allows for complex geometries and tight tolerances, delivering high-quality, durable spare parts.

Product parameters

| List | Details |

|---|---|

| Brand Name | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys, Plastic |

| Type | DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | Customers' Requirement |

| Size | Customized Size\Client's Drawings |

| Process | Cnc Machining + Surface Treatment |

| Finish | Drawing Request |

| Tolerance | Customer's Drawing Request |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Copper Sheet

Brass Sheet

Metal Sheet

Aluminum Sheet

Quality Control

CNC processing of spare parts offers highly precise and reliable manufacturing for custom components, ensuring they meet specific industry requirements. The short QC process plays a crucial role in maintaining the quality and functionality of these parts by focusing on critical areas like dimensional accuracy, material verification, surface quality, and overall part integrity. By adhering to strict QC standards, manufacturers can deliver durable, high-performance spare parts that meet customer specifications and ensure the smooth operation of machines and systems across various industries.

Processing capability

Short processing capability refers to the key aspects of a manufacturing process that ensure efficient production of custom components with high precision and quality. In the context of CNC processing for spare parts, the short processing capabilities typically include:

- recision Machining: The ability to produce highly accurate parts with tight tolerances, ensuring that each component meets the exact specifications required.

- Material Versatility: The capability to work with a wide range of materials, such as metals (steel, aluminum, brass) and plastics, offering flexibility in production.

- Complex Geometries: CNC machines can handle intricate and complex designs, allowing for the creation of parts with detailed features, such as threads, holes, and curves.

Additional processes

- Rapid Turnaround: Fast setup times and automated processes enable quick production of parts, making it ideal for both small and large batches.

- Customization: Ability to produce bespoke parts based on specific customer requirements, including custom shapes, sizes, and finishes.

- Repeatability: CNC processing ensures consistent quality across multiple parts, ensuring uniformity for high-volume production.

These capabilities allow manufacturers to produce high-quality, custom spare parts quickly, efficiently, and accurately, meeting the needs of various industries.