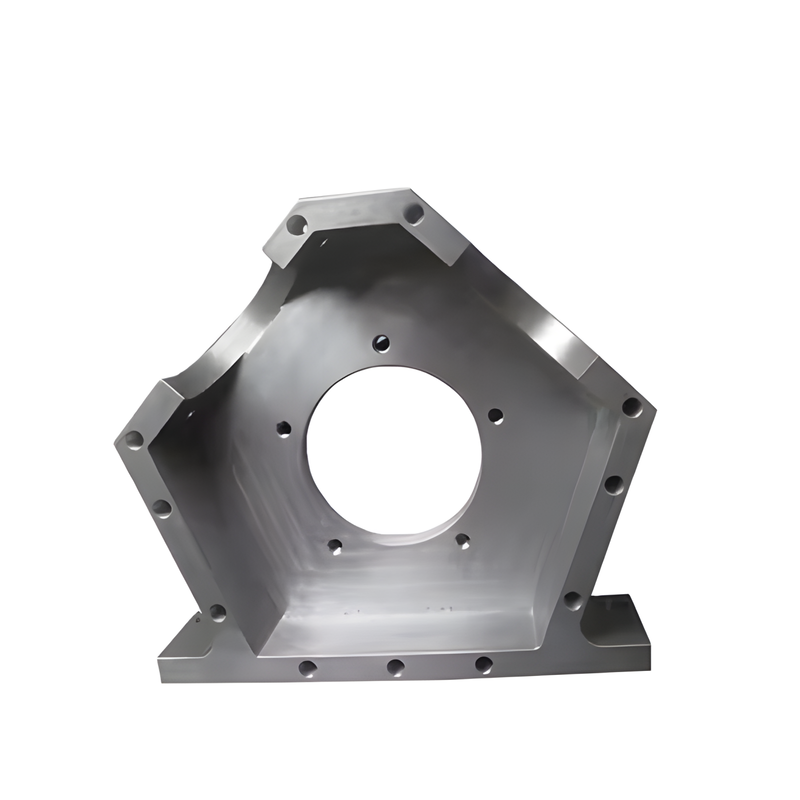

Product Description

Precision CNC Turning and Milling of Aluminum involves the use of advanced CNC (Computer Numerical Control) machines to shape and fabricate aluminum components with high accuracy. CNC turning and milling are key processes used to create precise, complex parts by removing material from a solid aluminum workpiece.

- CNC Turning: Involves rotating the aluminum part while a cutting tool is applied to it, creating cylindrical shapes, threads, or grooves with tight tolerances.

- CNC Milling: Uses rotating cutters to remove material from the aluminum workpiece in various directions, allowing for more intricate designs, holes, and surface finishes.

Product parameters

| List | Details |

|---|---|

| Product name | CNC stainless steel machining |

| Material Capabilities | Metal |

| Type | Other Machining Services |

| Model Number | CNC stainless steel machining 2 |

| Process | Cnc Machining+deburrs |

| Surface treatment | Customer's Request |

| Service | Customer's OEM |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

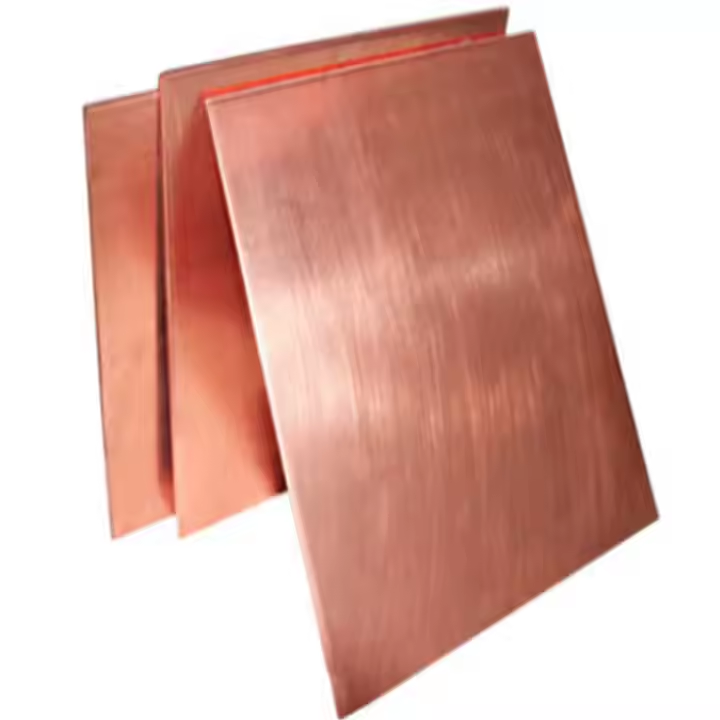

Copper Sheet

Brass Sheet

Metal Sheet

Aluminum Sheet

Quality Control

The QC (Quality Control) for precision CNC turning and milling of aluminum ensures that each part meets strict standards for accuracy, functionality, and finish. It includes checks for dimensional accuracy using precise measuring tools to verify tolerances. Material integrity is inspected to ensure the aluminum used meets specifications. Surface quality is assessed for smoothness, with any imperfections or burrs addressed. The parts undergo visual inspection for defects such as cracks or discoloration. Lastly, fit and functionality tests ensure the parts perform as required in their final application.

Processing capability

Processing capability for precision CNC turning and milling of aluminum encompasses several key aspects that ensure high-quality, accurate, and efficient manufacturing of custom parts:

- High Precision: CNC turning and milling machines can achieve tight tolerances (often within microns), ensuring parts meet exact specifications.

- Complex Geometries: Capable of producing intricate shapes, threads, holes, and contours, allowing for the creation of detailed and complex designs.

- Material Versatility: CNC machines can work with a wide range of aluminum grades and alloys, offering flexibility in material selection for different applications.

Additional processes

- Multi-Axis Machining: Advanced CNC machines offer multi-axis capabilities (3-axis, 5-axis) to produce parts from different angles without repositioning, improving efficiency and precision.

- High Production Volume or Custom Runs: These machines are capable of both small-batch and high-volume production, making them suitable for a wide range of manufacturing needs.

- Surface Finishing: CNC processes allow for precise control of surface finishes, achieving smooth, polished, or textured finishes depending on the part's requirements.

These capabilities ensure that precision CNC turning and milling of aluminum can meet the stringent demands of industries such as aerospace, automotive, and electronics, producing parts with exceptional accuracy, strength, and performance.