คำอธิบายผลิตภัณฑ์

การตอกสแตนเลส เป็นกระบวนการผลิตที่ใช้เครื่องตอกเพื่อขึ้นรูปแผ่นสแตนเลสให้เป็นรูปร่างต่าง ๆ เช่น การตัด เจาะ หรือรูปทรงซับซ้อน กระบวนการนี้ได้รับความนิยมในการผลิตชิ้นส่วนที่มีความทนทานและความแม่นยำสูงในอุตสาหกรรมต่าง ๆ เช่น ยานยนต์ อากาศยาน และอิเล็กทรอนิกส์ กระบวนการนี้รวมถึงเทคนิคต่าง ๆ เช่น การตัดทิ้ง (blanking) การเจาะ (punching) และการขึ้นรูปลึก (deep drawing) ซึ่งมีข้อดีในเรื่องของความเร็วในการผลิตที่สูง ประสิทธิภาพในการใช้วัสดุ และความทนทานต่อการกัดกร่อนที่ยอดเยี่ยม ทำให้เหมาะสมสำหรับชิ้นส่วนที่ต้องการความแข็งแรงและอายุการใช้งานที่ยาวนาน.

พารามิเตอร์ผลิตภัณฑ์

| รายการ | รายละเอียด |

|---|---|

| ชื่อแบรนด์ | การกลึง CNC |

| ความสามารถด้านวัสดุ | อะลูมิเนียม, ทองเหลือง, ทองสัมฤทธิ์, ทองแดง, โลหะแข็ง, โลหะมีค่า, สแตนเลส, โลหะผสมเหล็ก, พลาสติก |

| ประเภท | การเจาะ, การตัดด้วยเลเซอร์, การมิลลิ่ง, บริการการกลึงอื่น ๆ, การกลึง, การตัดด้วยสาย EDM, การสร้างต้นแบบอย่างรวดเร็ว |

| วัสดุ | ตามความต้องการของลูกค้า |

| ขนาด | ขนาดที่ปรับแต่งตามแบบของลูกค้า |

| กระบวนการ | การกลึง CNC + การตกแต่งพื้นผิว |

| การตกแต่ง | ตามคำขอของแบบ |

| ความคลาดเคลื่อน | ตามคำขอในแบบของลูกค้า |

กระบวนการที่กำหนดเอง

1.ส่งคำสอบถาม

2.แบบวาดหรือชิ้นตัวอย่าง

3.การเสนอราคา

4.การยืนยันจากลูกค้า

5.สั่งซื้อและชำระเงิน

6.การผลิตจำนวนมาก

7.การทดสอบก่อนบรรจุภัณฑ์

8.การจัดส่งและการยืนยัน

ประเภทกระบวนการ

วัสดุ

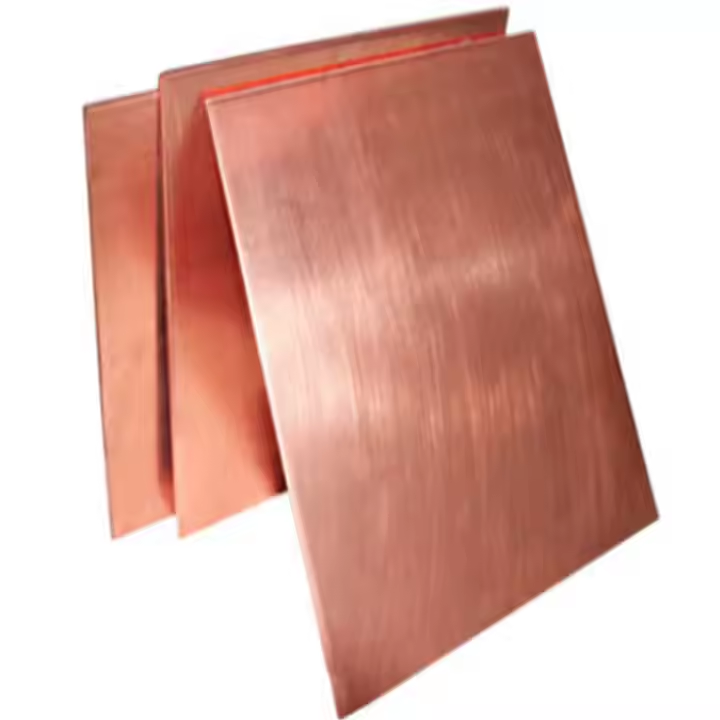

แผ่นทองแดง

แผ่นทองเหลือง

แผ่นเหล็ก

แผ่นอลูมิเนียม

การควบคุมคุณภาพ

Short QC คือ การทำควบคุมคุณภาพในลักษณะที่กระชับหรือย่อส่วน โดยมุ่งเน้นการตรวจสอบที่สำคัญและจำเป็นแทนการทดสอบแบบละเอียด เพื่อให้แน่ใจว่าผลิตภัณฑ์ตรงตามมาตรฐานคุณภาพพื้นฐาน การทำ Short QC มีเป้าหมายเพื่อประหยัดเวลาและทรัพยากร ขณะเดียวกันยังคงรักษาคุณภาพของผลิตภัณฑ์ให้อยู่ในระดับที่ยอมรับได้ วิธีนี้มักจะเกี่ยวข้องกับการตรวจสอบคุณลักษณะที่สำคัญ เช่น มิติ การตกแต่งพื้นผิว หรือการทำงาน โดยใช้วิธีที่เรียบง่ายหรือระบบอัตโนมัติ Short QC มักใช้ในสภาพแวดล้อมการผลิตที่มีปริมาณสูง ซึ่งความเร็วในการผลิตเป็นสิ่งสำคัญ แต่ก็ยังคงต้องมีการควบคุมคุณภาพเพื่อให้มั่นใจว่าผลิตภัณฑ์ตรงตามข้อกำหนดของอุตสาหกรรม.

ความสามารถในการประมวลผล

ความสามารถในการประมวลผลของการตอกสแตนเลส หมายถึง ความสามารถของอุปกรณ์และกระบวนการตอกในการแปลงแผ่นสแตนเลสให้เป็นชิ้นส่วนที่มีคุณภาพสูงและมีความแม่นยำได้อย่างมีประสิทธิภาพและถูกต้อง กระบวนการนี้ครอบคลุมปัจจัยหลายประการที่กำหนดว่าแผ่นสแตนเลสจะสามารถถูกขึ้นรูปและประมวลผลได้ดีเพียงใดสำหรับการใช้งานต่าง ๆ.

กระบวนการอื่น ๆ

ข้อดีของความสามารถในการประมวลผลของการตอกสแตนเลส:

- ความทนทานสูง: ความต้านทานต่อสนิมและการกัดกร่อนของสแตนเลสทำให้ชิ้นส่วนมีอายุการใช้งานยาวนาน โดยเฉพาะในสภาพแวดล้อมที่มีความรุนแรง

- ประหยัดต้นทุน: การตอกช่วยให้สามารถผลิตชิ้นส่วนคุณภาพสูงในปริมาณมากด้วยขยะวัสดุน้อย

- ความแม่นยำ: เทคโนโลยีการตอกที่ทันสมัยทำให้สามารถผลิตชิ้นส่วนที่มีความแม่นยำและความสามารถในการทำซ้ำสูง ซึ่งเป็นสิ่งสำคัญสำหรับชิ้นส่วนที่มีความคลาดเคลื่อนน้อย

- สรุป: ความสามารถในการประมวลผลของการตอกสแตนเลสถูกกำหนดโดยความสามารถในการจัดการกับวัสดุสแตนเลสหลากหลายประเภท ผลิตชิ้นส่วนที่ซับซ้อนและแม่นยำ รวมถึงการรักษาประสิทธิภาพและคุณภาพสูง ทำให้กระบวนการนี้เป็นกระบวนการที่สำคัญในอุตสาหกรรมที่ต้องการชิ้นส่วนที่ทนทานและมีประสิทธิภาพสูง.