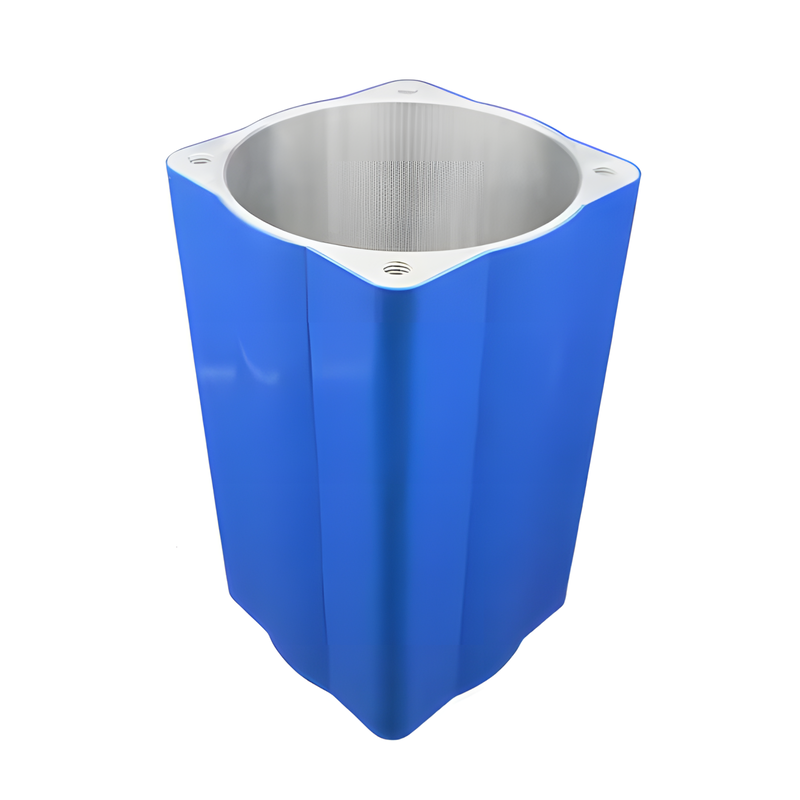

Product Description

A 5-axis aluminum CNC stamping machine is a precision tool used for machining complex aluminum parts. It combines the capabilities of a CNC milling machine with a stamping process, enabling the production of highly detailed and accurate components. With five axes of movement, the machine can manipulate the workpiece in multiple directions, allowing for intricate shapes, angles, and cuts. This process is commonly used in industries such as aerospace, automotive, and electronics, where precision and complexity are crucial.

Product parameters

| List | Details |

|---|---|

| Brand Name | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| QC control | 100% inspection,ROHS |

| deal with | CNC turning,CNC milling |

| tolerance | 0.01 mm |

| size | Custom size |

| device | CNC machining center |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

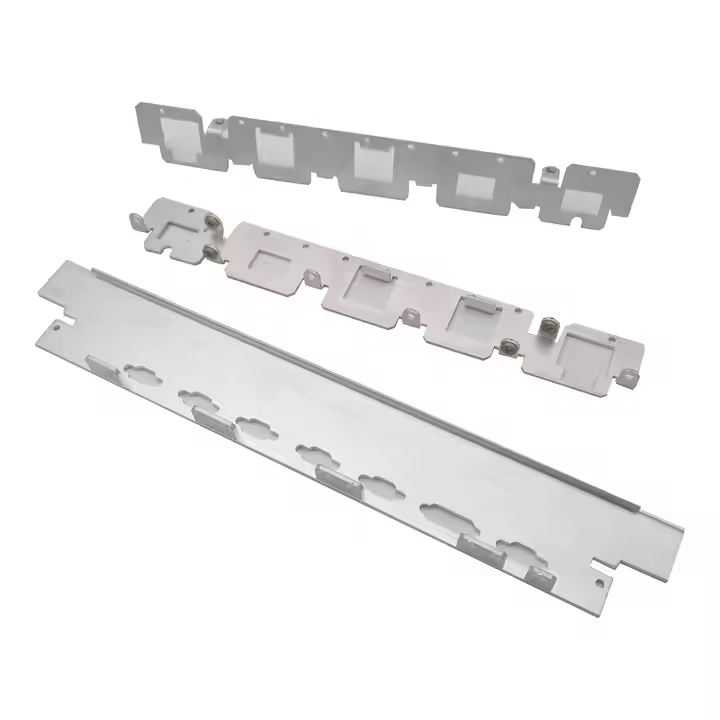

Process Type

Material

Copper Sheet

Brass Sheet

Metal Sheet

Aluminum Sheet

Quality Control

Streamlined or abbreviated approach to quality control processes in manufacturing. It focuses on key quality checks that ensure products meet essential standards without the extensive testing typically involved in full QC procedures. Short QC aims to save time and resources while still maintaining acceptable levels of quality assurance. It often involves a selective inspection of critical aspects of the product, such as dimensions, surface finish, or functionality, using automated systems or quick manual checks. This approach is commonly used in high-volume production settings where speed and efficiency are prioritized, but quality is still a key focus.

Processing capability

Processing capability refers to the ability of a manufacturing system, machine, or production process to perform a set of tasks within defined parameters, such as precision, speed, and efficiency. It encompasses various factors, including:

Machine Capacity: The ability of machines or equipment (like CNC machines, lathes, or presses) to handle specific workloads, materials, and complexity of tasks.

Material Handling: The system's ability to work with different materials, such as metals, plastics, or composites, under various conditions (e.g., temperature, pressure).

Precision and Tolerance: The level of accuracy a system can achieve in terms of part dimensions, surface finish, and overall quality. This is crucial for industries requiring high precision, such as aerospace or medical device manufacturing.

Additional processes

Speed and Efficiency: The system’s throughput, or how quickly it can process materials or produce finished products, often influencing the cost and time of production.

Flexibility: The capacity to adapt to changes in production schedules, design modifications, or diverse product types without significant downtime or reconfiguration.

In summary, processing capability defines how well a manufacturing system can meet production demands based on its technical specifications, material handling, and adaptability, ensuring that quality and efficiency are maintained throughout the production cycle.