产品描述

D系列工业激光扫描雷达是砝石激光雷达(FaseLase)研制的一款微型激光雷达,它融合了光纤压缩专利、电磁非接触式旋转专利、无源光电编码专利等技术,可看清周边360度范围20米内的物体(型号不同性能不同),比蜜蜂的视野还大,并且可产生所在空间的平面点云地图数据。这些点云地图数据可应用于地图测绘、机器人定位导航、人流量检测等领域。

产品参数

| 型号(Model) | D6 | D10 | D20 |

|---|---|---|---|

| 测量距离 | 0.15~6m@10% | 0.15~10m,6m@10% | 0.15~20m,12m@10% |

| Measuring distance | |||

| 角度分辨率 | - | 0.36° | 0.28° |

| Angle resolution | |||

| 扫描速度 | 10Hz | 10Hz | 10Hz |

| Scanning speed | |||

| 输出接口 | TTL/USB和3*NPN OUT,2*NPN IN | TTL/USB | TTL/USB |

| Output Interface | |||

| 供电 | DC5V±10%,<3W;启动电流>1.5A | ||

| Power supply | |||

| 扫描区域 | 360° | ||

| Scanning area | |||

| 重复精度 | ±4cm | ||

| Repeatability | |||

| 距离分辨率 | 1cm | ||

| Distance resolution | |||

| 光源 | 激光二极管905nm,≤1mW;符合GB7247.1-2001;I类激光人眼安全要求 | ||

| light source | Laser diode 905nm, ≤1mW; Meets GB7247.1-2001; Class I laser human eye safety requirements | ||

| 机械尺寸 | 78x78x56 mm | ||

| Dimensions | |||

| 操作温度范围 | -10℃~+50℃ | ||

| Operating temperature | |||

| 存储温度范围 | -20℃~+70℃ | ||

| storage temperature | |||

| 防护等级 | IP55 | ||

| Protection level | |||

| 重量 | 190g | ||

| Weight | |||

产品展示

● SLAM构图精度可达到1%

● 零位及角度精度

● 支持ROS机器人操作系统

● 可外部时序控制进行超密集安装,通过CAN连接形成3D扫描

● 采用人眼安全保护激光,符合标准

激光点云数据D20可SLAM建图

可看清周边 360 度范围 20米内的物体,比蜜蜂的视野还大,并且可产生所在空间的平面点云地图数据

采用日本进口轴承定制的高精密的无刷电机,在标准条件下使用,使用寿命是5万小时

在光学方面,他们采用TOF激光测距法和一级人眼安全保护激光,符合国际国内标准,并且高功率激光发射管使用光纤压缩(公司专利)进行发散角压缩,使其光斑变小,从而大大提高了我的视力。

在机械方面,他们采用了电磁非接触式旋转专利技术和无源光电编码专利技术使结构简单,并通过采用大转轴外转子电机使其机器性能非常稳定,从而使我大大提高方位感。

在电学与数据处理方面,对激光雷达探射到物体边缘所产生的误报进行过滤处法处理,对于探射到透明物体我们可以通过能量返回处法可加以区分,去虚景能力大大提高,误码率下降。除通过PWM 对旋转电机的启动、停止以及旋转速度进行控制外,采用负反馈原理对电机转速进行实时稳定,使我判断更准确,

在使用性方面,可通过转接板提供RS232、RS485、USB多种输出方式,可外部时序控制进行超密集安装通过CAN连接,形成3D扫描。提供功能强大的激光点云地图构建软件和功能强大的激光点云原始数据分析软件。

应用案例

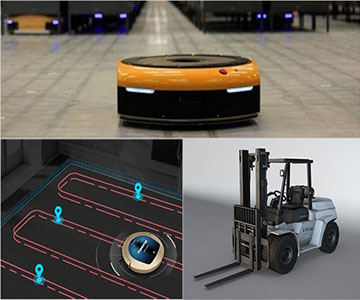

深圳市砝石激光雷达有限公司FaseLase专门为无人车开发的具同步地图构建、路径规划与导航、自动防撞等的场景需求解决方案。室内服务机器人、商用移动机器人、室内投屏互动,AGV、叉车、立体停车库。

合作伙伴