Product Description

OEM sheet metal parts production with accurate cutting, bending, and forming. We provide high-quality parts designed for different industries, with reliable service and on-time delivery

Product parameters

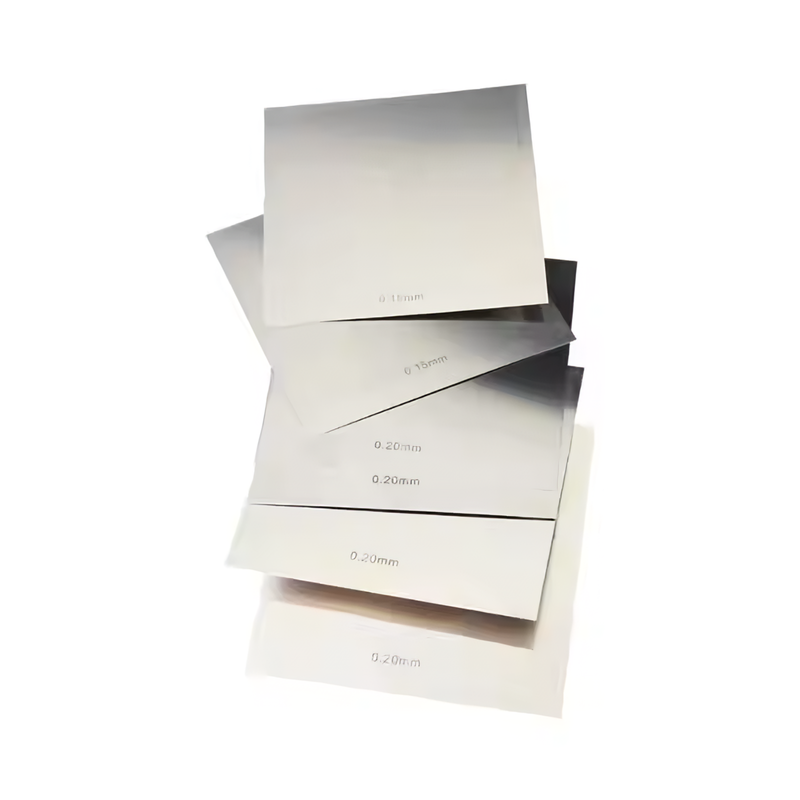

| Material : | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet.Iron 5) Brass, copper ETC.... |

| Tolerance : | +/-0.01mm |

| Dimension : | Customized |

| Thickness: | +/- 0.005--0.02mm / can also be customized. |

| Prototype: | Available |

| Drawing Format: | Step, dwg, igs, pdf |

| Design and Advise: | Design and Skilled Support, Put Your Good Ideal into Reality. |

| MOQ: | Low MOQ Start 1 Pcs ( No need mold cost ) , Many Customer found us make prototype product to save Investment Funds for Pre-R&D and Market Testing |

| Sample Cost: | Free of Sample Cost. Normally is USD 35~110 per Style If Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order. |

| Sample time: | Common products 1-2 days after received drawing and payment |

| Delivery Time: | 1-25 days after order with prepayment based on products structure and quantity |

| Payment Terms: | Only 30% Deposit, Make Your Floating Capital More Effective. |

| Shipping: | By Air or Sea. If Choose by Air, it is Faster Like You Purchase from Local Market. |

| Others Services: | When You Become Our VIP, You Can Enjoy Our Distributor Price and All Your Orders will Have the First Priority to Arrange Production and etc. |

| Quality Control: | Computer quality control system |

| Service Type: | OEM/ODM |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

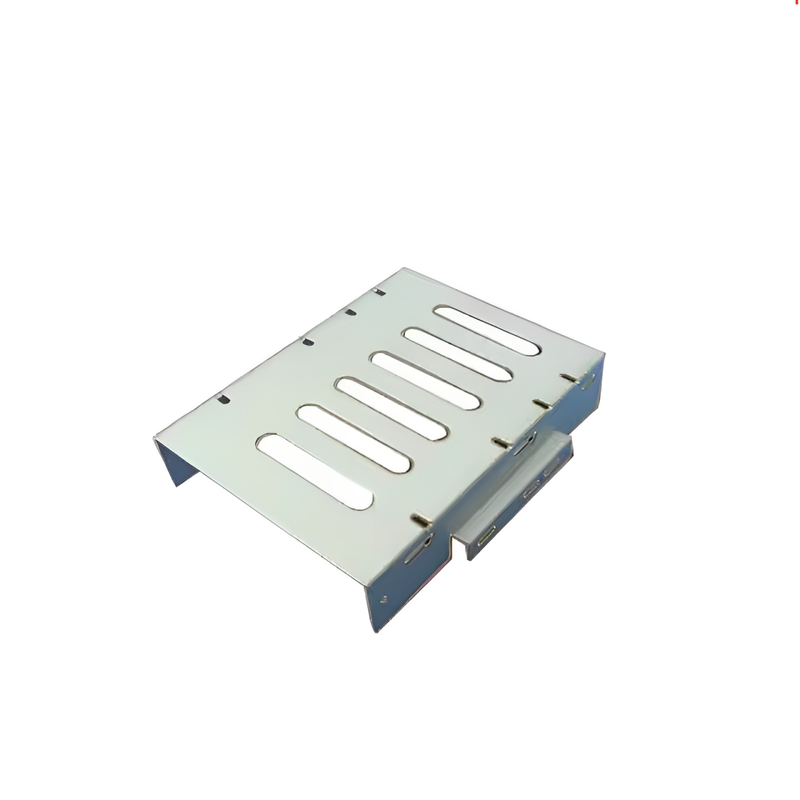

Battery Mount for Mobile Robots

Reason:

This part's sturdy structure and versatile design, with multiple pre-drilled holes, make it ideal for securely mounting batteries or electrical components. It ensures the battery stays firmly in place, minimizing vibrations during robot movement across uneven surfaces or in cases of sudden impacts. This improves the stability and lifespan of the robot's electrical system, making it highly suitable for mobile robots used in dynamic environments.

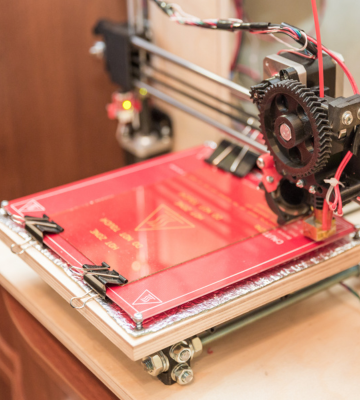

Component for 3D Printers

Reason:

3D printers require precise structures to support axis drives or motors controlling the print head's movement. This part's holes and slots are ideal for mounting such equipment and routing cables or control systems. Moreover, the frame reduces vibrations during the printing process, ensuring high-quality, smooth, and accurate 3D prints. It enhances the overall stability and operational efficiency of the printer.

Mini CNC Machine Frame

Reason:

This part is highly suitable for the base of small CNC machines due to its strength and precision. It includes pre-drilled holes for mounting motors, couplings, and linear axes, ensuring smooth and accurate movements. The sturdy structure minimizes twisting or vibrations during material cutting, which is critical for producing high-quality, consistent parts. This makes it an excellent choice for small-scale machining and prototyping applications.

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in sheet metal OEM production involves inspecting materials, monitoring processes, and verifying finished parts for accuracy, surface quality, and performance. Advanced tools like CMM and laser measurement systems ensure dimensional precision, while post-production checks focus on coatings and functional tests. Compliance with standards like ISO 9001 ensures consistent, high-quality results that meet customer requirement

Processing capability

The processing capability of sheet metal OEM production includes laser cutting, CNC punching, and precision bending for accurate shapes and dimensions. Welding processes like TIG and MIG ensure durable assemblies, while additional capabilities such as stamping and rolling expand design possibilities. Surface treatments like powder coating and anodizing enhance durability and appearance, meeting customer-specific requirements

Additional processes

Additional processes in sheet metal parts production for OEMs include processes like embossing, which creates raised or recessed patterns on the surface for both functional and aesthetic purposes. Surface finishing methods such as powder coating, anodizing, and plating are used to enhance corrosion resistance, improve durability, and give a polished appearance. Furthermore, deburring and polishing are carried out to remove sharp edges or excess material from the parts to ensure safety and improve the part’s overall quality. Custom packaging and assembly processes may also be included, where parts are pre-assembled or packaged for shipping, ensuring the parts reach the customer in optimal condition. Automation is often integrated into these processes to increase efficiency and consistency across large production volumes