Product Description

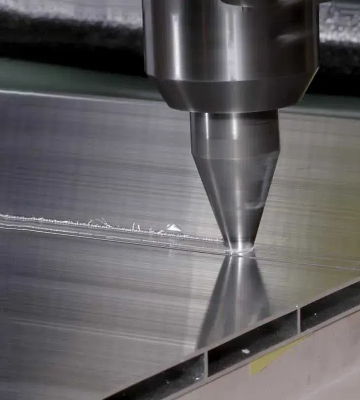

A laser welding CNC (Computer Numerical Control) system integrates advanced laser welding technology with CNC capabilities, allowing for highly automated, precise, and programmable welding operations. The CNC system controls the movement of the laser and workpiece, enabling complex, intricate welds with high accuracy and repeatability. This system is commonly used for welding small to medium-sized components in industries like automotive, aerospace, and electronics, where precision and consistency are critical. The CNC functionality allows for customizable weld patterns, speeds, and power settings, improving efficiency and quality in production environments.

Product parameters

| List | Details |

|---|---|

| Brand Name | laser welding |

| Thickness | 0.1mm-12mm |

| Surface treatment | Electric plating,powder coated,sand blasting,lacquer |

| Testing | Salt spray |

| Certification | ISO 9001:2008, RoHS |

| Process | Punching, stamping, bending, riveting, etc |

| Application | Construction, Automotive,Industrial, electronic, |

| Material | Stainless Steel;Aluminum;Iron;Brass;Copper |

Custom Process

Design and Programming

Machine Setup

Welding Process Execution

Inspection and Finishing

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

Quality control (QC) of a laser welding CNC system focuses on ensuring consistent, precise welds and system performance. It includes verifying the accuracy of CNC programming and the alignment of the laser to ensure proper weld placement. The system’s parameters, such as power, speed, and focus, must be regularly calibrated for optimal results. QC also involves monitoring the cooling, fume extraction, and safety features to maintain a safe working environment. Regular inspections of the laser's performance, system components, and cleanliness are essential. Proper QC ensures the system meets industry standards for reliability, precision, and safety.

Processing capability

The processing capability of a laser welding CNC system is defined by its ability to perform high-precision, automated welding on a wide range of materials, including metals, plastics, and ceramics. With CNC integration, the system can execute complex, intricate weld patterns with extreme accuracy, making it ideal for applications in industries such as aerospace, automotive, and electronics. The CNC control allows for precise adjustments to laser power, speed, and focus, enabling customization for different material thicknesses and joint types.

Additional processes

Laser welding CNC systems are capable of producing high-quality welds with minimal heat-affected zones, reducing distortion and maintaining the integrity of the workpiece. They can handle a variety of welding tasks, including butt joints, fillet welds, and seam welding, often with high repeatability. The integration of real-time process monitoring and adaptive control ensures consistent quality, while the workpiece is precisely positioned using automated systems.

Additionally, the system can be integrated with automated inspection technologies like vision systems or sensors to verify weld quality and ensure that every weld meets stringent standards. The advanced capabilities of the laser welding CNC system increase production efficiency, reduce human error, and ensure reliable, repeatable welds for demanding industrial applications.