Product Description

Custom sheet metal fabrication is the process of designing, cutting, bending, and assembling sheet metal to create parts or products tailored to specific requirements. It utilizes advanced techniques such as laser cutting, CNC punching, welding, and forming to produce precise, custom components. This process is commonly used across industries like automotive, aerospace, construction, and electronics. Custom fabrication offers the flexibility to adjust dimensions, materials, and finishes to meet both functional and aesthetic needs. It provides a cost-effective, durable solution for producing complex or one-of-a-kind metal parts with high precision and versatility.

Product parameters

| List | Details |

|---|---|

| Brand Name | Welding & Cutting part |

| Color | Customized Colors |

| OEM/ODM | OEM ODM CNC Milling Turning Machining Service |

| MOQ | Small Orders Accepted |

| Logo | Accept Custom Logo |

| Service | Customized OEM CNC Machining |

| Application | Industrial Equipment |

| Equipment | CNC Machining Centres |

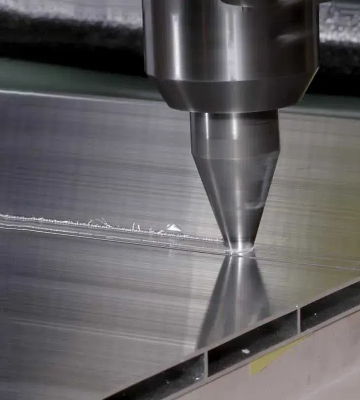

Custom Process

Design and Programming

Machine Setup

Welding Process Execution

Post-Welding Inspection

Process Type

Solid State Welding

Newer Welding

Gas Welding

Material

Metal

Aluminum

Copper

Brass

Quality Control

custom sheet metal fabrication ensures that all parts meet the required standards and customer specifications. The process begins with a thorough inspection of raw materials, including checks on thickness, material grade, and surface finish. During production, dimensional checks, visual inspections, and non-destructive testing are conducted to maintain accuracy and prevent defects. QC also involves monitoring key fabrication processes such as welding, cutting, and bending to avoid issues like warping or misalignment. Once fabrication is complete, parts undergo testing for strength, durability, and functionality. Detailed documentation of QC results is typically provided to verify compliance with industry standards and customer requirements.

Processing capability

Custom sheet metal fabrication offers a diverse array of processing capabilities for producing highly precise and specialized components. Key techniques include laser cutting, which provides clean, accurate cuts for intricate shapes and tight tolerances, and water jet cutting, ideal for materials sensitive to heat. CNC punching allows for fast, efficient creation of holes, slots, and other features, while CNC bending ensures precise angles and complex shapes. MIG and TIG welding deliver strong, durable joints, with versatility to work with various metals. Forming processes such as deep drawing and stamping enable the mass production of uniform parts.

Additional processes

Additional capabilities, like rolling and brake forming, allow for the creation of curved or cylindrical components, enhancing design flexibility. Custom sheet metal fabrication accommodates a wide range of materials, including steel, aluminum, stainless steel, brass, and copper, selected based on strength, weight, and corrosion resistance. Finishing options such as powder coating, anodizing, and galvanizing offer durability, corrosion resistance, and aesthetic enhancements. Precision machining and CNC milling are available for high-precision adjustments. These capabilities make custom sheet metal fabrication ideal for industries like automotive, aerospace, medical devices, and electronics, where quality, precision, and customization are essential.