Product Description

Our company has been a leader in high-precision machining for over 21 years, specializing in delivering high-quality, custom solutions to meet the unique needs of our clients. With decades of experience and expertise in the field, we understand the critical importance of precision, reliability, and consistency in every project we undertake.

At the core of our business philosophy is a dedication to continuous improvement, innovation, and excellence in all that we do. As we look to the future, we remain focused on staying at the forefront of technology and ensuring that we continue to meet the evolving demands of our clients.

Product parameters

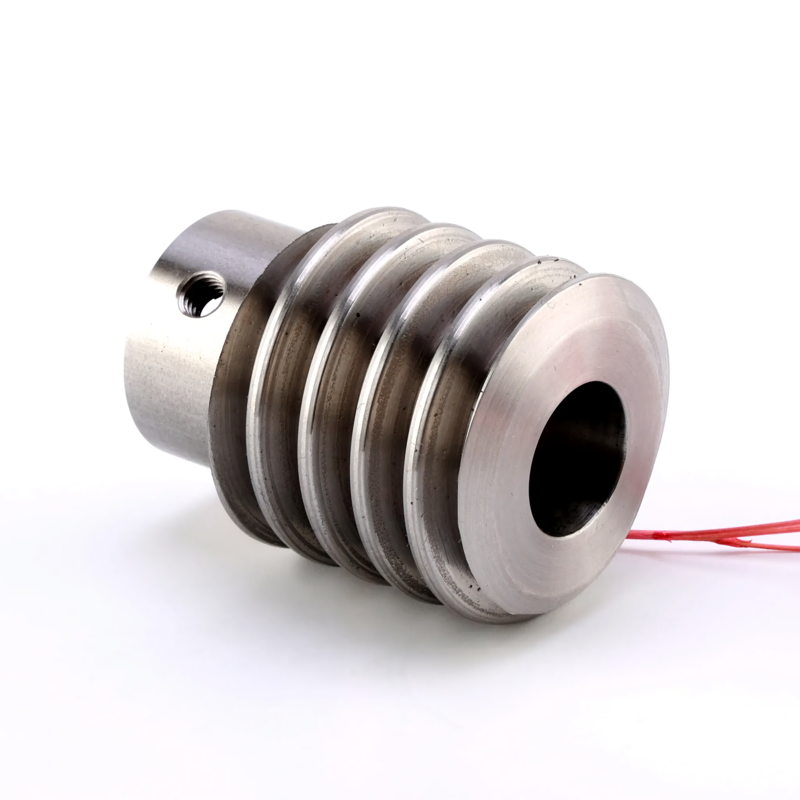

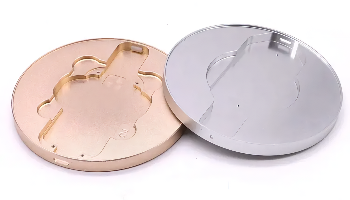

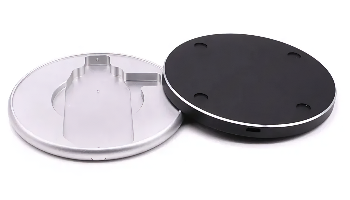

| Material | Aluminium Alloy,stainless steel,metal |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| MOQ | 100pcs, according to your drawings |

| QC System | 100% inspection before shipment, product OK rate 99.8% |

| Drawing | Provide by customer, or design according as the sample |

| Drwing format | Pro/E, AutoCAD, Solidworks, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. |

| Payment term | T/T, Erik pay, West Union,etc |

Custom Process

1. Product Design

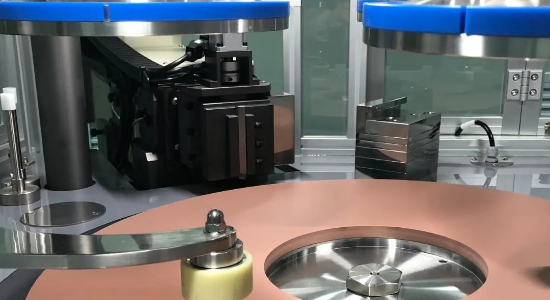

2. CNC Turning / Milling

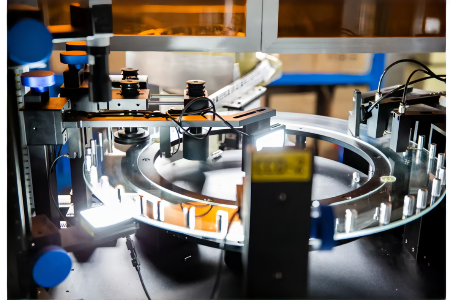

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Material

Aluminu Alloy

Stainless Steel

Aluminum-Alloy Block

Brass

Copper

Tube Material

Special Steel

Contact Us

Quality Control

- Consistent calibration and inspection tool

- Optional XRF analysis report

- Well-equipped inspection department

- Materials inspection by IQC

- FQC will check the products

- 100% inspected by OQC before shipping

- Designated area for nonconforming products

- Root cause analysis of unqualified

Additional processes

Lapping and Polishing

· Applications: Often used in semiconductor manufacturing, optical lenses, and high-precision mechanical components like bearings or gears.

· Key Benefits: Provides ultra-smooth finishes and precise dimensional accuracy, often with very tight tolerances.

Super finishing

· Applications: Often used for precision bearings, automotive crankshafts, and aerospace components.

· Key Benefits: Achieves exceptional surface finishes with very low roughness values, improves component performance, and extends the life of the parts.