Product Description

We are committed to providing tailored machining services that meet the specific requirements of each client, no matter how complex or unique. Whether it's a small batch of specialized components or large-scale production runs, our skilled team and advanced equipment ensure that every product meets the highest standards of accuracy and craftsmanship.

Our clients trust us not only because of our technical capabilities but also because of our unwavering commitment to quality. Many of our customers choose to return to us time and again for their machining needs, building long-term relationships based on the reliability of our products and services. With a customer-focused approach, we take pride in offering solutions that help our clients succeed in their own industries.

Product parameters

| Material | Aluminum (6061-T6, 6063, 7075-T6,5052) etc... Brass/Copper/Bronze etc... Stainless Steel (302, 303, 304, 316, 420) etc... Steel (mild steel, Q235, 20#, 45#) etc... Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

| Process | CNC Machining, CNC turning, CNC milling, CNC lathe machining, CNC boring, CNC grinding, CNC drilling etc... |

| Surface treatment | Clear/color anodized; Hard anodized; Powder-coating; Sand-blasting; Painting; Nickel plating; Chrome plating; Zinc plating; Silver/gold plating; Black oxide coating, Polishing etc... |

| Gerenal Tolerance (+/-mm) | CNC Machining: 0.005 Turning: 0.005 Grinding(Flatness/in2): 0.003 ID/OD Grinding: 0.002 Wire-Cutting: 0.002 |

| Certification | ISO9001:2008, ROHS |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 20 years of CNC machining products 3 years of automation machine manufacturing |

| Packaging | Standard: pearl cotton and bubble bag, carton box and seal For large and big quantity: pallet or as per customers' requirement |

| Lead time | In general:7-15days |

| Term of Payment | T/T, Paypal, Trade Assurance etc... |

| Minimum Order | Comply with customer's demand |

Custom Process

1. Product Design

2. CNC Turning / Milling

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Material

Aluminu Alloy

Stainless Steel

Aluminum-Alloy Block

Brass

Copper

Tube Material

Special Steel

Contact Us

Quality Control

Consistent calibration and inspection tool

Optional XRF analysis report

Well-equipped inspection department

Materials inspection by IQC

FQC will check the products

100% inspected by OQC before shipping

Designated area for nonconforming products

Root cause analysis of unqualified

Additional processes

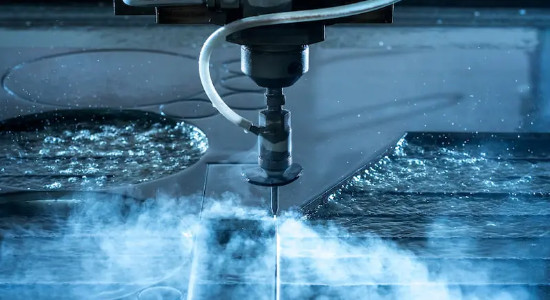

Water Jet Cutting

· Applications: Used in industries where heat-sensitive materials are involved, such as aerospace, automotive, and stone cutting.

· Key Benefits: Can cut through a wide range of materials, no thermal distortion, and suitable for intricate shapes.