คำอธิบายผลิตภัณฑ์

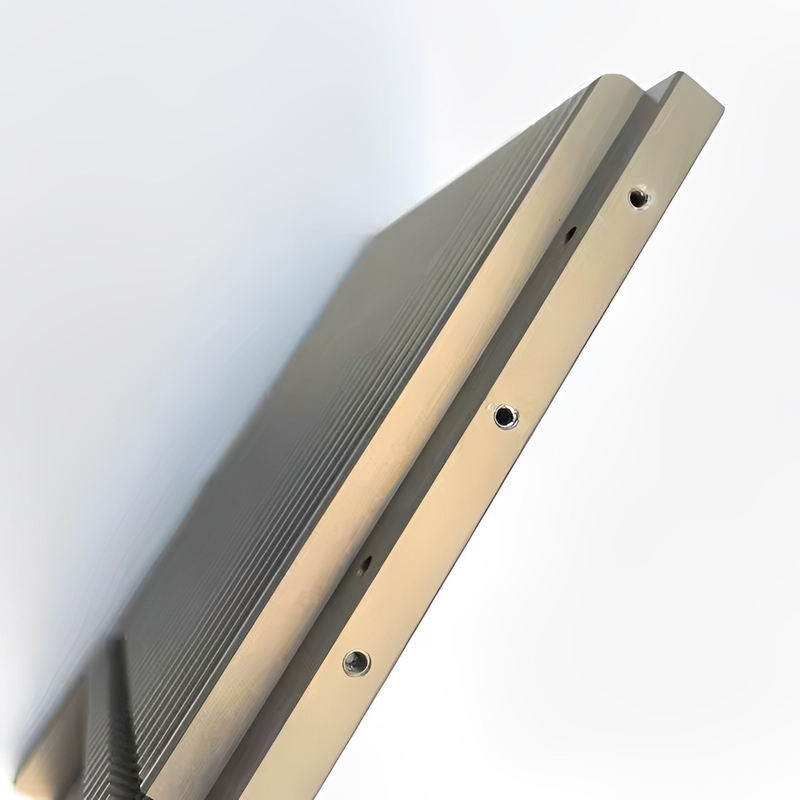

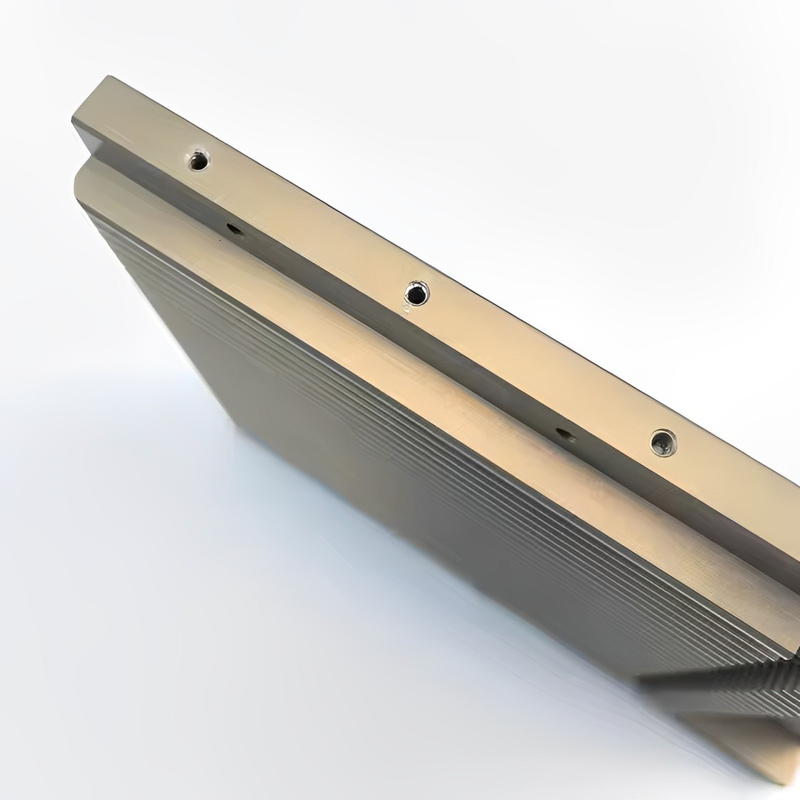

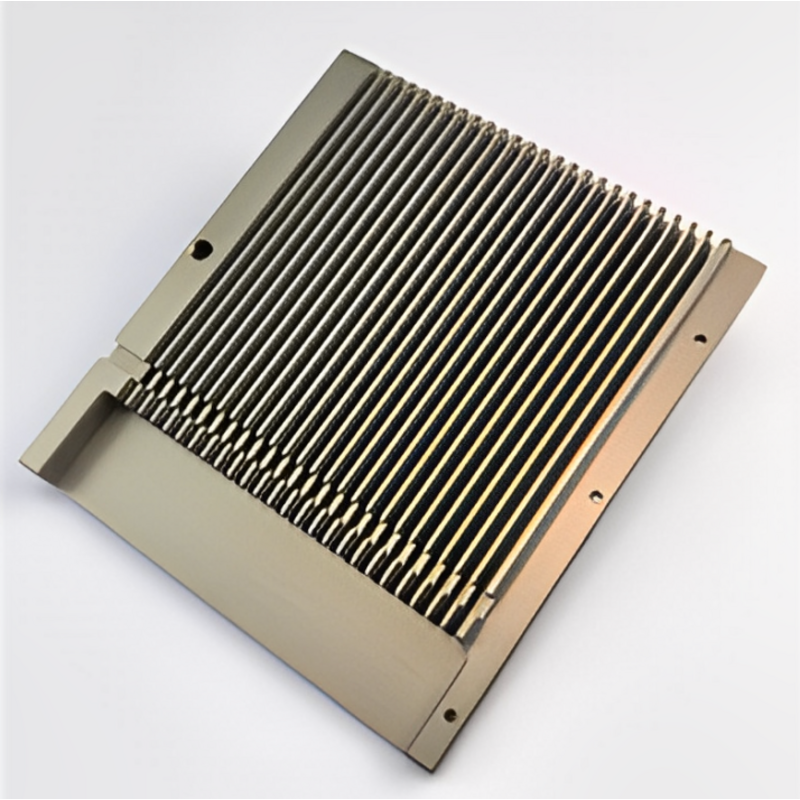

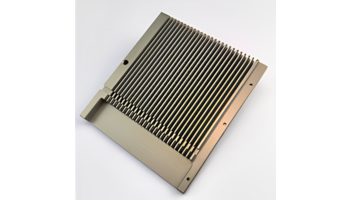

ชิ้นส่วนเครื่องจักรระดับพรีเมียมที่ถูกสร้างขึ้นอย่างพิถีพิถันด้วยความแม่นยำและความทนทานสูง มอบความน่าเชื่อถือและประสิทธิภาพที่ไม่เหมือนใครเพื่อตอบสนองความต้องการในอุตสาหกรรมที่ซับซ้อนในระดับโลก

พารามิเตอร์ผลิตภัณฑ์

| ชื่อผลิตภัณฑ์ | ชิ้นส่วนเครื่องจักร |

| ขนาด | สั่งทำพิเศษ |

| การใช้งาน | อุปกรณ์อุตสาหกรรม |

กระบวนการที่กำหนดเอง

1. ส่งคำถามหรือการสอบถาม

2. ส่งแบบหรือ Drawing

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. เริ่มทำการผลิต

7. ทดสอบก่อนบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

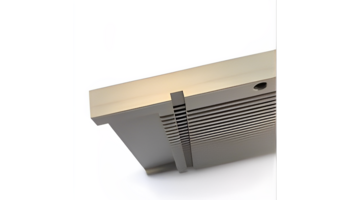

Engine Blocks

เหตุผลในการใช้งาน: ชิ้นส่วนเหล่านี้มักจะทำโดยใช้กระบวนการหล่อแม่นยำร่วมกับการกลึง CNC การหล่อช่วยให้สามารถผลิตรูปร่างที่ซับซ้อนได้อย่างรวดเร็วและคุ้มค่า ในขณะที่การกลึง CNC ช่วยให้ผลิตภัณฑ์สุดท้ายมีมิติที่แม่นยำตามที่ต้องการสำหรับการประกอบเครื่องยนต์ กระบวนการเหล่านี้ยังช่วยให้บล็อกมีความแข็งแรงและการกระจายน้ำหนักที่เหมาะสมเพื่อการทำงานของเครื่องยนต์.

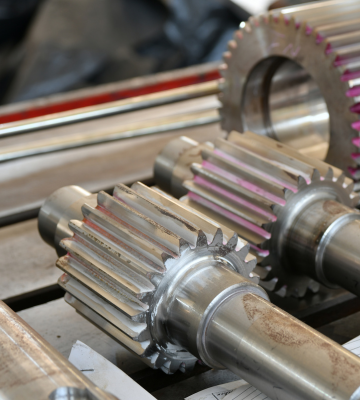

Gear Shafts

เหตุผลในการใช้งาน: ก้านเฟืองมักจะผลิตโดยการหมุน CNC และการขัดพื้นผิว ตามด้วยการบำบัดความร้อน การหมุนช่วยให้ก้านมีรูปทรงตามสเปคที่แม่นยำ ในขณะที่การขัดพื้นผิวจะทำให้ได้ผิวที่เรียบและละเอียด ซึ่งช่วยลดการเสียดทานระหว่างการใช้งาน การบำบัดความร้อนมีความสำคัญเพื่อเพิ่มความแข็งของวัสดุ ทำให้ก้านสามารถทนต่อแรงบิดสูงได้โดยไม่สึกหรอเร็วเกินไป.

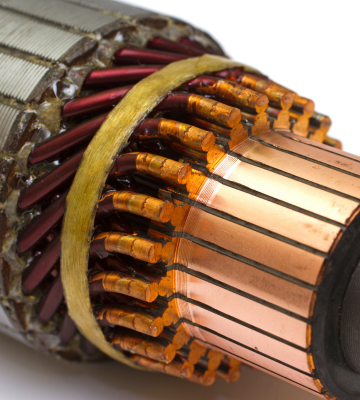

Rotors

เหตุผลในการใช้งาน: โรเตอร์มักผลิตผ่านกระบวนการหมุน CNC และการกัด CNC ซึ่งช่วยให้สามารถสร้างรูปร่างที่ซับซ้อนได้ โดยมั่นใจได้ถึงความสมดุลและความแม่นยำในการหมุนของชิ้นส่วน การบำบัดความร้อนใช้เพื่อเพิ่มความแข็งแรงและความต้านทานการสึกหรอของโรเตอร์ ซึ่งเป็นสิ่งสำคัญในการรองรับความเร็วสูงและการเสียดทานในมอเตอร์หรือเทอร์ไบน์.

วัสดุ

โลหะผสมอะลูมิเนียม

สแตนเลสสตีล

การควบคุมคุณภาพ

การควบคุมคุณภาพสำหรับชิ้นส่วนเครื่องจักรประกอบด้วยการทดสอบและการตรวจสอบอย่างละเอียดเพื่อให้มั่นใจในความแม่นยำ ความทนทาน และประสิทธิภาพ เทคโนโลยีขั้นสูง เช่น เครื่อง CNC และเครื่องมือในการตรวจสอบ จะช่วยยืนยันความถูกต้องของมิติ คุณภาพผิว และความสมบูรณ์ของโครงสร้าง ชิ้นส่วนที่ไม่ตรงตามมาตรฐานที่กำหนดจะได้รับการแก้ไขก่อนการจัดส่ง เพื่อให้มั่นใจในความน่าเชื่อถือและประสิทธิภาพของชิ้นส่วนในการใช้งานในอุตสาหกรรม

ความสามารถในการประมวลผล

การควบคุมคุณภาพสำหรับชิ้นส่วนเครื่องจักรประกอบด้วยการทดสอบและการตรวจสอบอย่างละเอียดเพื่อให้มั่นใจในความแม่นยำ ความทนทาน และประสิทธิภาพ เทคโนโลยีขั้นสูง เช่น เครื่อง CNC และเครื่องมือในการตรวจสอบ จะช่วยยืนยันความถูกต้องของมิติ คุณภาพผิว และความสมบูรณ์ของโครงสร้าง ชิ้นส่วนที่ไม่ตรงตามมาตรฐานที่กำหนดจะได้รับการแก้ไขก่อนการจัดส่ง เพื่อให้มั่นใจในความน่าเชื่อถือและประสิทธิภาพของชิ้นส่วนในการใช้งานในอุตสาหกรรม

กระบวนการอื่น ๆ

กระบวนการเพิ่มเติมสำหรับชิ้นส่วนเครื่องจักรประกอบด้วยการบำบัดความร้อนเพื่อปรับปรุงความแข็ง ความแข็งแรง และความต้านทานการสึกหรอของวัสดุ กระบวนการทำผิวเช่นการขัดเงา การอโนไดซ์ และการเคลือบจะช่วยเพิ่มความสวยงาม ป้องกันการกัดกร่อน และให้ผิวที่เรียบเพื่อการทำงานที่ดีขึ้น การเคลือบเช่นการเคลือบผงหรือการชุบสังกะสีช่วยเพิ่มความทนทานของชิ้นส่วน กระบวนการต่างๆ เช่น การเชื่อม การตัดเลเซอร์ และการขัดละเอียดก็สามารถนำมาใช้เพื่อให้ได้รูปร่างที่ซับซ้อน โดยมั่นใจว่าชิ้นส่วนตรงตามข้อกำหนดการออกแบบเฉพาะและมาตรฐานของอุตสาหกรรม กระบวนการเหล่านี้ช่วยยืดอายุการใช้งานและเพิ่มความน่าเชื่อถือของชิ้นส่วนเครื่องจักร ทำให้เหมาะสมกับการใช้งานในอุตสาหกรรมที่ต้องการประสิทธิภาพสูง.