Product Description

Our company has been a leader in high-precision machining for over 21 years, specializing in delivering high-quality, custom solutions to meet the unique needs of our clients. With decades of experience and expertise in the field, we understand the critical importance of precision, reliability, and consistency in every project we undertake.

We are committed to providing tailored machining services that meet the specific requirements of each client, no matter how complex or unique. Whether it's a small batch of specialized components or large-scale production runs, our skilled team and advanced equipment ensure that every product meets the highest standards of accuracy and craftsmanship.

Product parameters

| Material | Aluminium Alloy,stainless steel,metal |

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| MOQ | 100pcs, according to your drawings |

| QC System | 100% inspection before shipment, product OK rate 99.8% |

| Drawing | Provide by customer, or design according as the sample |

| Drwing format | Pro/E, AutoCAD, Solidworks, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. |

| Payment term | T/T, Erik pay, West Union,etc |

Custom Process

1. Product Design

2. CNC Turning / Milling

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Material

Aluminu Alloy

Stainless Steel

Aluminum-Alloy Block

Brass

Copper

Tube Material

Special Steel

Contact Us

Quality Control

- Consistent calibration and inspection tool

- Optional XRF analysis report

- Well-equipped inspection department

- Materials inspection by IQC

- FQC will check the products

- 100% inspected by OQC before shipping

- Designated area for nonconforming products

- Root cause analysis of unqualified

Additional processes

Abrasive Jet Machining (AJM)

Applications: Commonly used for cleaning hard-to-reach areas, deburring sharp edges, or cutting fragile or soft materials like plastics or ceramics.

Key Benefits: Capable of producing fine finishes, good for fragile materials, and can be used for very intricate parts.

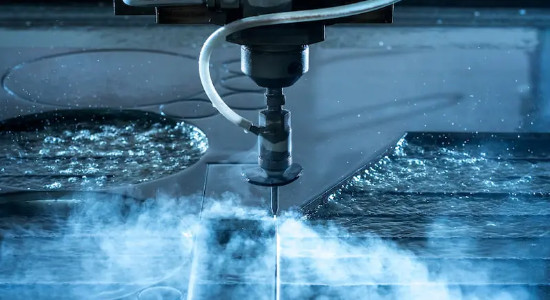

Water Jet Cutting

· Applications: Used in industries where heat-sensitive materials are involved, such as aerospace, automotive, and stone cutting.

· Key Benefits: Can cut through a wide range of materials, no thermal distortion, and suitable for intricate shapes.