คำอธิบายผลิตภัณฑ์

เครื่องมือกล Lathe สำหรับโลหะเป็นอุปกรณ์ที่ออกแบบมาอย่างแม่นยำสำหรับการขึ้นรูปและการทำงานชิ้นส่วนโลหะ มันมาพร้อมกับการควบคุมขั้นสูงสำหรับการกลึง การตัด และการทำเกลียวของวัสดุโลหะที่หลากหลาย ด้วยความสามารถในการทำงานที่ความเร็วสูงและการสร้างที่ทนทาน จึงมั่นใจได้ในประสิทธิภาพและความทนทานที่ยอดเยี่ยม เครื่องนี้เหมาะสำหรับการผลิตชิ้นส่วนที่มีความคลาดเคลื่อนแคบและพื้นผิวที่เรียบ ทำให้เหมาะสำหรับอุตสาหกรรมต่างๆ เช่น ยานยนต์, การบิน, และการผลิตทั่วไป อินเทอร์เฟซที่ใช้งานง่ายและการตั้งค่าที่ปรับแต่งได้ช่วยเพิ่มประสิทธิภาพการผลิตและการทำงาน เครื่อง Lathe นี้มอบความสามารถในการใช้งานที่หลากหลายทั้งการผลิตขนาดเล็กและขนาดใหญ่.

พารามิเตอร์ผลิตภัณฑ์

| รายการ | รายละเอียด |

|---|---|

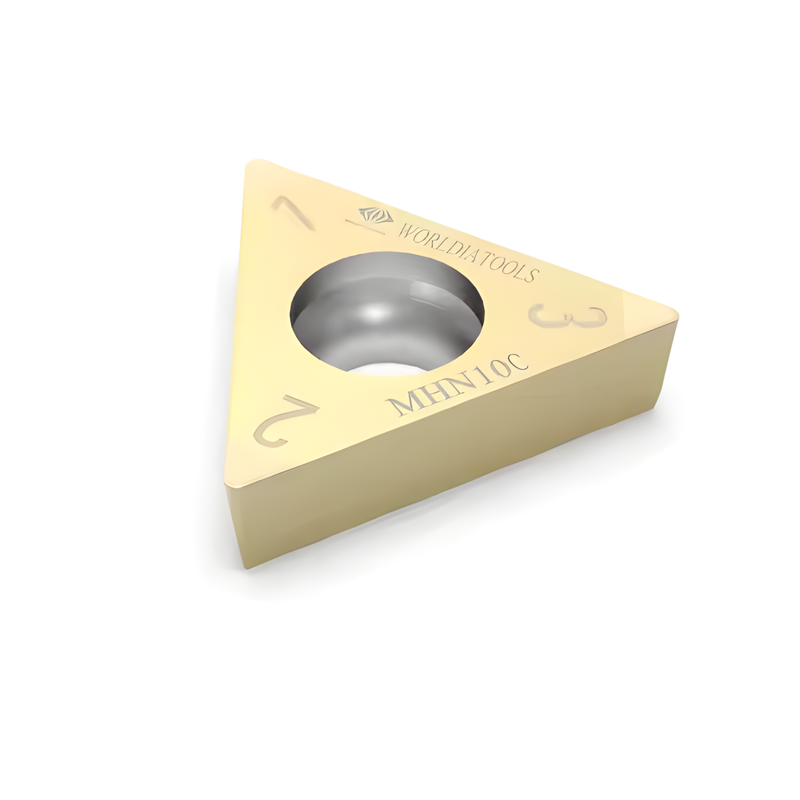

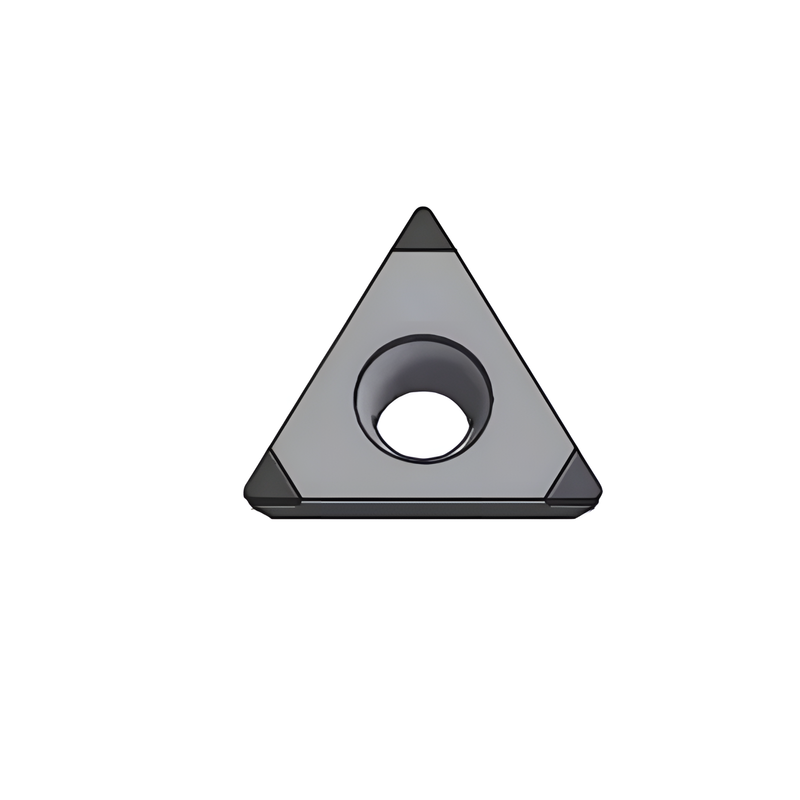

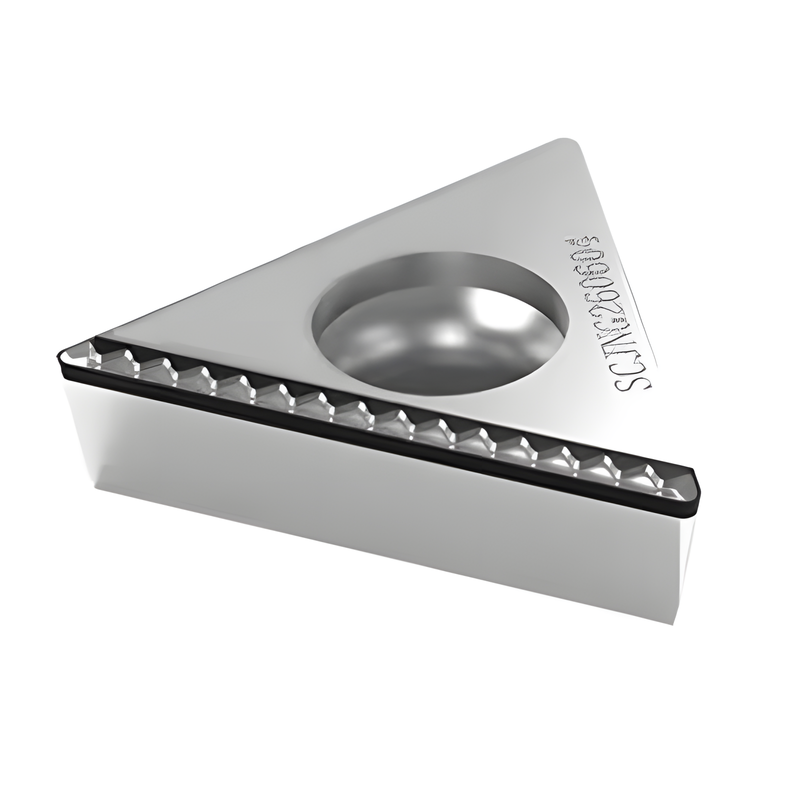

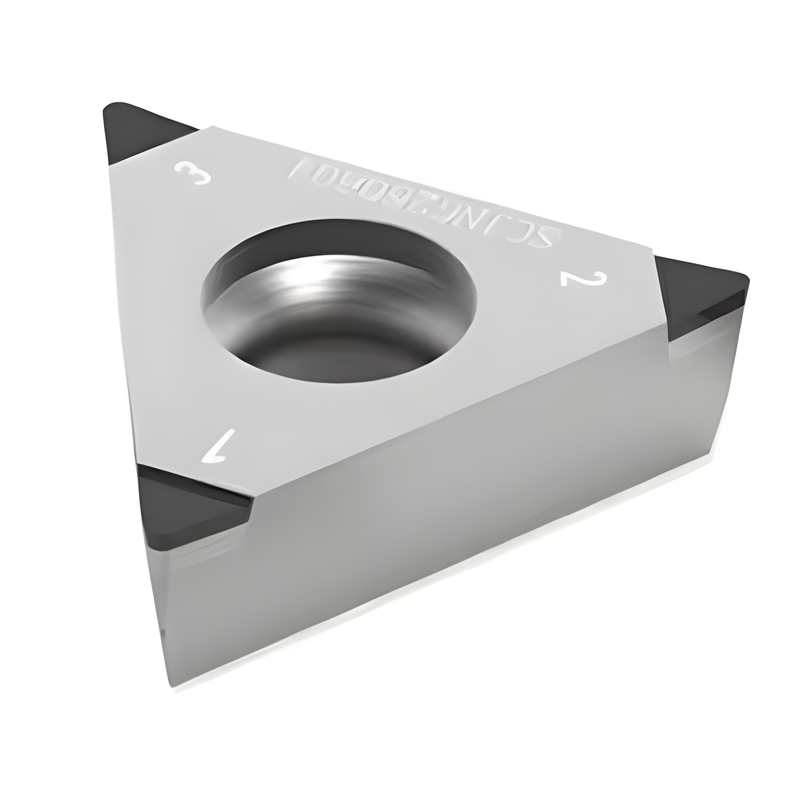

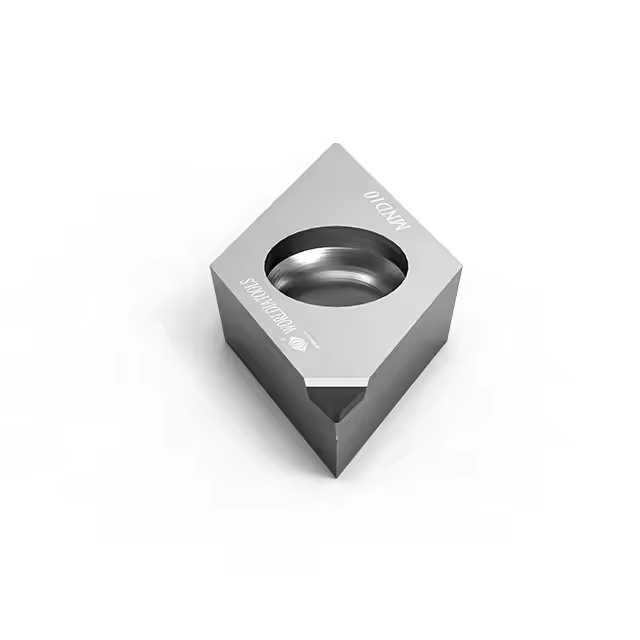

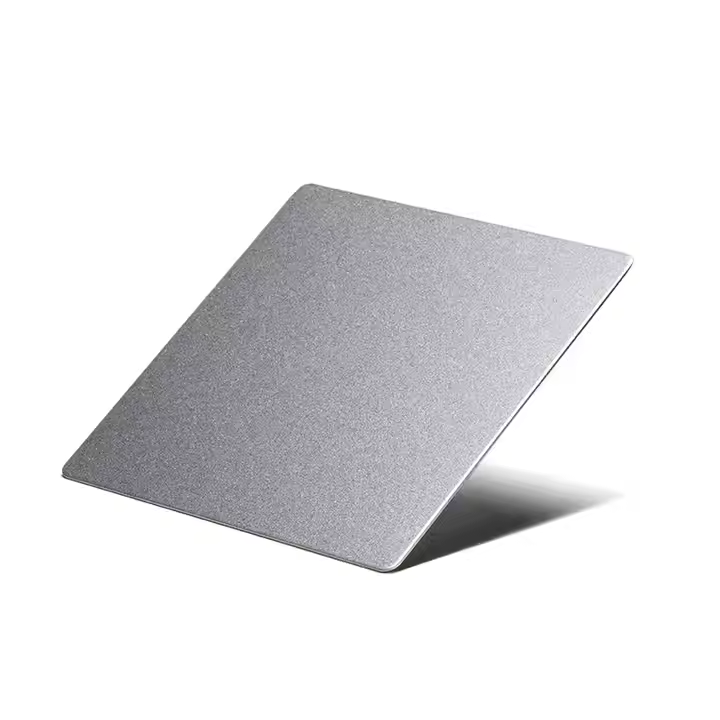

| สินค้า | ดอกตัดกลึง |

| การเคลือบผิว | เคลือบผิว |

| การสนับสนุนที่กำหนดเอง | OEM, ODM, OBM |

| วัสดุ | PCBN + คาร์ไบด์ |

| ใบรับรอง | ISO9001, 14001, 18001, RoHS |

| เกรด PCD/PCBN | MHN10C |

| การใช้งาน | การตัดที่ขัดจังหวะเบาของเหล็กชุบแข็ง |

กระบวนการที่กำหนดเอง

1. ส่งคำถามหรือการสอบถาม

2. ส่งแบบหรือ Drawing

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. เริ่มทำการผลิต

7. ทดสอบก่อนบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

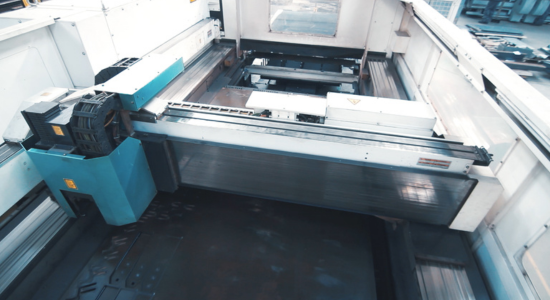

การกัดและการเจาะ

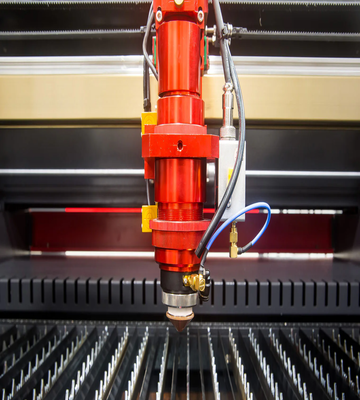

การตัดเลเซอร์

การกลึง

วัสดุ

อลูมิเนียม

ทองเหลือง

ทองแดง

การควบคุมคุณภาพ

การควบคุมคุณภาพ (QC) สำหรับเครื่องมือกล Lathe สำหรับโลหะรับรองประสิทธิภาพที่แม่นยำและเชื่อถือได้ตลอดการใช้งาน ซึ่งรวมถึงการตรวจสอบชิ้นส่วนทั้งหมดอย่างละเอียดเพื่อตรวจหาข้อบกพร่อง ความสมบูรณ์ของวัสดุ และความคลาดเคลื่อนในการผลิต เครื่องจะได้รับการทดสอบอย่างครบถ้วนสำหรับการจัดตำแหน่ง ความแม่นยำ และฟังก์ชันการทำงาน ผิวสัมผัสและมิติที่สำคัญจะได้รับการตรวจสอบเพื่อให้เป็นไปตามข้อกำหนดที่กำหนด ประสิทธิภาพของเครื่องจะได้รับการประเมินภายใต้เงื่อนไขการใช้งานต่างๆ เพื่อให้มั่นใจในคุณภาพที่สม่ำเสมอ มาตรการควบคุมคุณภาพยังรวมถึงการตรวจสอบความทนทานและคุณสมบัติด้านความปลอดภัยเพื่อรับประกันอายุการใช้งานที่ยาวนานของเครื่อง.

ความสามารถในการประมวลผล

เครื่องมือกล Lathe สำหรับโลหะมีความสามารถในการประมวลผลที่กว้างขวางสำหรับงานโลหะทุกประเภท มันมาพร้อมกับการควบคุม CNC ขั้นสูงสำหรับการทำงานที่แม่นยำและอัตโนมัติ ช่วยให้สามารถกลึง การทำเกลียว และการตัดได้อย่างมีความแม่นยำ เครื่องนี้สามารถรองรับโลหะได้หลากหลายประเภท เช่น เหล็ก อะลูมิเนียม ทองเหลือง และทองแดง พร้อมทั้งความยืดหยุ่นในการปรับให้เหมาะสมกับความแข็งและขนาดของวัสดุต่างๆ มันมีความสามารถในการตัดที่ความเร็วสูง ช่วยให้การผลิตชิ้นส่วนที่ซับซ้อนและมีความคลาดเคลื่อนแคบเป็นไปได้อย่างมีประสิทธิภาพ

ด้วยสปินเดิลที่ทรงพลังและการออกแบบที่แข็งแกร่ง เครื่องนี้จึงมั่นใจได้ว่าจะตัดได้อย่างราบรื่นและปราศจากการสั่นสะเทือน ผลิตพื้นผิวที่มีคุณภาพสูง นอกจากนี้ยังมาพร้อมกับตัวเปลี่ยนเครื่องมืออัตโนมัติ ซึ่งเพิ่มความยืดหยุ่นในการตั้งเครื่องมือหลายแบบโดยไม่ต้องแทรกแซงด้วยมือ เครื่องนี้สามารถทำการตัดหลายแกน ซึ่งเหมาะสำหรับการสร้างรูปทรงซับซ้อนและคุณลักษณะชิ้นส่วนที่ละเอียด.

กระบวนการอื่น ๆ

นอกจากนี้ เครื่องนี้ยังสามารถใช้สำหรับการเจาะ การเจาะรู และการทำผิวหน้า ซึ่งเพิ่มความหลากหลายในการทำงานเครื่องจักรประเภทต่างๆ

การออกแบบแบบโมดูลาร์ของเครื่องทำให้สามารถปรับเปลี่ยนได้อย่างรวดเร็วสำหรับการผลิตทั้งในปริมาณน้อยและมาก ทำให้เหมาะสมกับอุตสาหกรรมต่างๆ เช่น ยานยนต์ การบิน และการผลิตทั่วไป ความสามารถในการใช้งานกับเครื่องมือการตัดและการตั้งเครื่องมือที่หลากหลายช่วยเพิ่มความยืดหยุ่นในการทำงานด้านการผลิต โดยมอบความแม่นยำสูงและการทำงานซ้ำได้อย่างต่อเนื่อง.