คำอธิบายผลิตภัณฑ์

ชิ้นส่วนอะไหล่โลหะผสมที่ผลิตด้วยเทคนิคการกลึง CNC เป็นชิ้นส่วนที่ออกแบบมาอย่างแม่นยำเพื่อประสิทธิภาพสูงและความทนทาน ผลิตจากวัสดุโลหะผสมคุณภาพสูงที่มีความแข็งแรง ทนต่อการสึกหรอและการกัดกร่อนได้ดี เหมาะสำหรับอุตสาหกรรมหลากหลายประเภท เช่น ยานยนต์ การบิน และการผลิตทั่วไป ชิ้นส่วนเหล่านี้ผลิตตามคำสั่งเพื่อให้ตรงกับข้อกำหนดการออกแบบที่เฉพาะเจาะจง โดยมีการควบคุมความคลาดเคลื่อนแคบและผิวที่เรียบ การันตีความเชื่อถือได้และความสม่ำเสมอ เพื่อให้ประสิทธิภาพที่ดีที่สุดในงานที่ต้องการประสิทธิภาพสูง เหมาะทั้งสำหรับการผลิตจำนวนมากและการออกแบบเฉพาะแบบ.

พารามิเตอร์ผลิตภัณฑ์

| รายการ | รายละเอียด |

|---|---|

| ชื่อสินค้า | ชิ้นส่วนการกลึง CNC |

| ความสามารถของวัสดุ | อลูมิเนียม, ทองเหลือง, ทองบรอนซ์, ทองแดง, โลหะที่ผ่านการแข็งตัว, โลหะมีค่า, สแตนเลส, โลหะผสมเหล็ก |

| ประเภท | การตัดโบรชิ่ง, การเจาะ, การกัดกรด/การตัดเคมี, การตัดเลเซอร์, การกัดมิลลิ่ง, บริการการกลึง, การตัดสายไฟ EDM, การสร้างต้นแบบด่วน |

| การบำบัดผิว | การอโนไดซ์, การออกซิไดซ์, การชุบเคลือบ |

| การใช้งาน | หุ่นยนต์, การบิน, ยานยนต์, อุปกรณ์การแพทย์ |

| สี | สีที่กำหนดเอง |

| คุณภาพ | คุณภาพสูง |

| บริการ | บริการ OEM และ ODM |

กระบวนการที่กำหนดเอง

1. ส่งคำถามหรือการสอบถาม

2. ส่งแบบหรือ Drawing

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. เริ่มทำการผลิต

7. ทดสอบก่อนบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

การกัดและการเจาะ

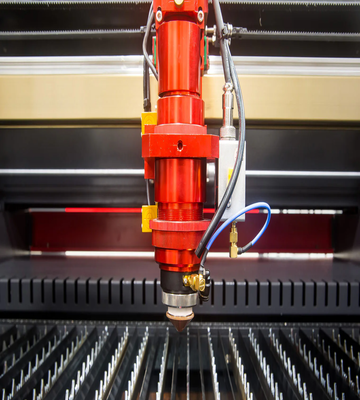

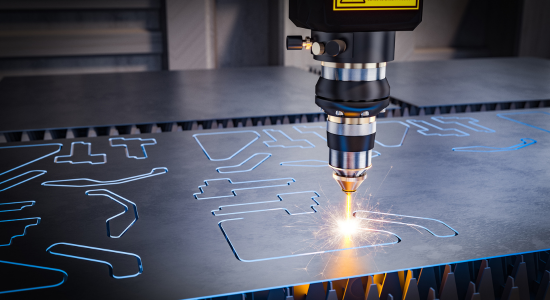

การตัดเลเซอร์

การกลึง

วัสดุ

อลูมิเนียม

ทองเหลือง

ทองแดง

การควบคุมคุณภาพ

การควบคุมคุณภาพ (QC) สำหรับชิ้นส่วนอะไหล่โลหะผสมที่ผลิตด้วยการกลึง CNC รวมถึงการตรวจสอบอย่างเข้มงวดในทุกขั้นตอนของการผลิต โดยแต่ละชิ้นส่วนจะถูกตรวจสอบความแม่นยำของขนาดเพื่อให้แน่ใจว่ามีความคลาดเคลื่อนที่แคบตามที่กำหนด การตรวจสอบความสมบูรณ์ของวัสดุจะดำเนินการเพื่อยืนยันว่าโลหะผสมที่ใช้ตรงตามข้อกำหนดความแข็งแรงและความทนทานที่ระบุ การตรวจสอบผิวสัมผัสจะทำเพื่อให้มั่นใจว่ามีความเรียบและไม่มีข้อบกพร่อง ชิ้นส่วนจะได้รับการทดสอบการทำงานเพื่อยืนยันประสิทธิภาพภายใต้สภาวะการใช้งาน การตรวจสอบขั้นสุดท้ายจะรวมถึงการตรวจสอบอย่างละเอียดในเรื่องของความสอดคล้อง ความเชื่อถือได้ และการปฏิบัติตามข้อกำหนดของลูกค้า เพื่อให้มั่นใจได้ในมาตรฐานคุณภาพสูงสุด.

ความสามารถในการประมวลผล

ชิ้นส่วนอะไหล่โลหะผสมที่ผลิตด้วยการกลึง CNC มอบความสามารถในการประมวลผลที่ยอดเยี่ยม ช่วยให้สามารถผลิตชิ้นส่วนที่มีความแม่นยำสูงและซับซ้อน โดยการใช้เทคโนโลยี CNC ขั้นสูง ชิ้นส่วนเหล่านี้สามารถกลึงได้ด้วยความคลาดเคลื่อนที่แคบและความแม่นยำสูง ซึ่งรับรองได้ว่าจะพอดีกับการใช้งานที่หลากหลาย กระบวนการผลิตประกอบด้วยการกลึง การมิลลิ่ง การเจาะ และการทำเกลียว ซึ่งช่วยให้สามารถออกแบบและตั้งค่าชิ้นส่วนได้หลากหลาย

ด้วยความสามารถในการรองรับวัสดุโลหะผสมหลากหลายประเภท เช่น อลูมิเนียม ทองเหลือง สแตนเลส และไทเทเนียม การกลึง CNC ช่วยให้ชิ้นส่วนมีความแข็งแรง ทนต่อการสึกหรอ และมีการป้องกันการกัดกร่อนได้ดี เครื่อง CNC ขั้นสูงสามารถตัดด้วยความเร็วสูง ทำให้การผลิตมีประสิทธิภาพในขณะที่ยังคงรักษาคุณภาพและความสม่ำเสมอไว้ได้.

กระบวนการอื่น ๆ

กระบวนการสามารถปรับแต่งได้ทั้งสำหรับการผลิตในปริมาณน้อยและมาก ทำให้เหมาะสมกับอุตสาหกรรมที่หลากหลาย เช่น ยานยนต์ การบิน การแพทย์ และอิเล็กทรอนิกส์ การกลึง CNC ยังช่วยให้สามารถสร้างการออกแบบที่ซับซ้อนได้ รวมถึงรูปทรงเรขาคณิตที่ซับซ้อนและคุณลักษณะที่ละเอียด ตัวเปลี่ยนเครื่องมืออัตโนมัติและความสามารถในการตัดหลายแกนเพิ่มความยืดหยุ่นในการผลิต ช่วยให้สามารถทำชิ้นส่วนที่มีความแม่นยำสูงและผิวที่เรียบ

นอกจากนี้ การกลึง CNC ยังรับประกันความสามารถในการทำซ้ำ ซึ่งหมายความว่าสามารถผลิตชิ้นส่วนในปริมาณมากด้วยคุณภาพและความแม่นยำของขนาดที่สม่ำเสมอ ทำให้เหมาะสำหรับทั้งการสร้างต้นแบบและการผลิตจำนวนมาก.