Product Description

Our company has years of extensive experience in the high-precision machining of robotic components. As a comprehensive supplier that integrates multiple vendors, we specialize in providing tailored services to meet the high demands of various robotic systems. Through continuous technological innovation and strict quality control, we are capable of manufacturing precision robotic parts suitable for a wide range of industrial applications, offering customized solutions to our clients.

Product parameters

| processing | CNC turning, CNC milling, Drilling, Grinding, Spinning, Wire-EDM Cutting, Stamping, Laser Cutting, Bending, Die Casting, Extrusion, Injection Molding |

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium: Grade F1-F5 | |

| Surface treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| quality assurance | ISO 9001:2015, SGS,16949,ROHS |

| Tolerant | +/-0.002~+/-0.005mm |

| Surface roughness | Min Ra 0.1~3.2 |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

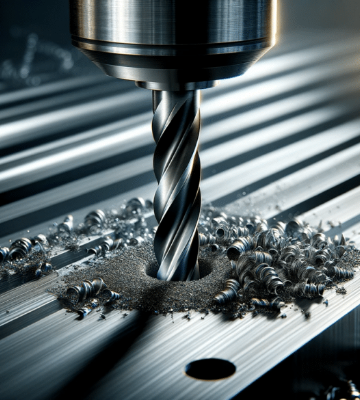

Drilling

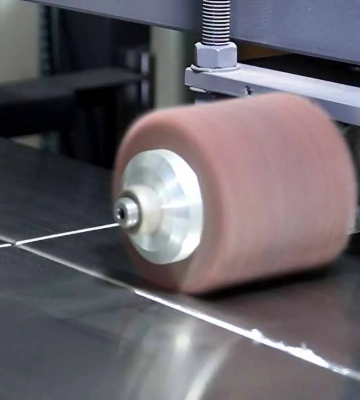

Deburring

Polishing

Material

Aluminum Alloy

Zinc Alloy

Alloy Steel

Stainless Steel

Quality Control

Quality is at the core of our CNC machining service. We adhere to rigorous quality control processes throughout the entire manufacturing process. From material selection to final inspection, we maintain strict adherence to industry standards and specifications. Our quality assurance measures include comprehensive inspections, dimensional accuracy checks, and surface finish assessments. By upholding the highest standards of quality, we ensure that your precision parts meet or exceed your expectations.

Processing capability

When it comes to precision parts CNC machining service, choose ERIK as your trusted partner. With our state-of-the-art technology, skilled team, unwavering commitment to quality, customization options, and timely delivery, we offer an exceptional CNC machining experience. Contact us today to discuss your precision parts CNC machining needs and unlock the full potential of your projects. Experience the precision and excellence that set us apart. Choose ERIK for unparalleled precision parts CNC machining service.

Additional processes

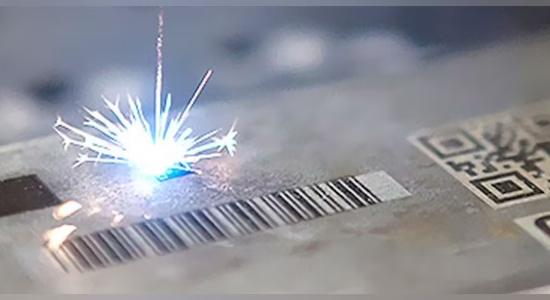

Laser Marking and Engraving

- Laser Marking: A high-precision process used to add identification marks, barcodes, serial numbers, or logos to parts. It uses a laser beam to alter the surface of the material without causing deformation.

- Laser Engraving: A more intense process where the laser is used to engrave designs or text on a part, commonly used in industries like aerospace or medical devices for permanent identification.

Advantage: High-precision engraving and marking without affecting the part’s integrity, ideal for traceability and aesthetic purposes.