Product Description

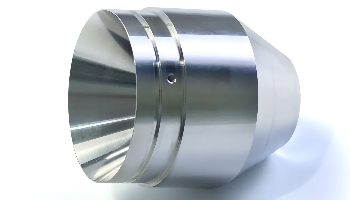

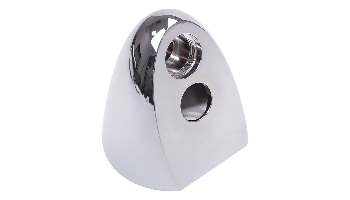

We have many years of rich experience in high-precision robotic component manufacturing. As a supplier that integrates multiple vendors, we offer professional, customized services to meet the demanding requirements of various robotic systems. Through continuous technological innovation and strict quality control, we are able to produce precision robotic components suitable for a wide range of industrial sectors, providing tailored solutions to our customers.

Product parameters

| processing | CNC turning, CNC milling, Drilling, Grinding, Spinning, Wire-EDM Cutting, Stamping, Laser Cutting, Bending, Die Casting, Extrusion, Injection Molding |

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

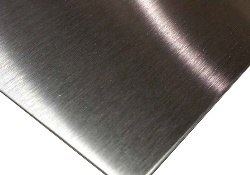

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium: Grade F1-F5 | |

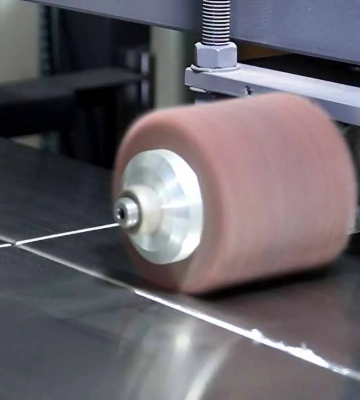

| Surface treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| quality assurance | ISO 9001:2015, SGS,16949,ROHS |

| Tolerant | +/-0.002~+/-0.005mm |

| Surface roughness | Min Ra 0.1~3.2 |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

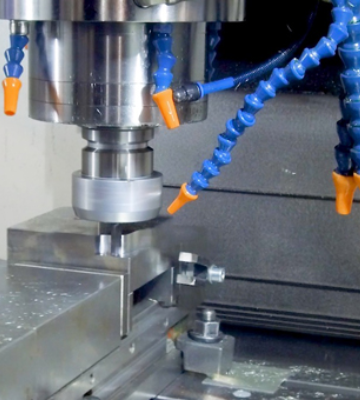

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

CNC Machining

Deburring

Polishing

Material

Aluminum Alloy

Zinc Alloy

Alloy Steel

Stainless Steel

Quality Control

Quality is at the core of our CNC machining service. We adhere to rigorous quality control processes throughout the entire manufacturing process. From material selection to final inspection, we maintain strict adherence to industry standards and specifications. Our quality assurance measures include comprehensive inspections, dimensional accuracy checks, and surface finish assessments. By upholding the highest standards of quality, we ensure that your precision parts meet or exceed your expectations.

Processing capability

Customization and Flexibility:

We understand that every project has unique requirements, and our CNC machining service offers customization and flexibility to meet your specific needs. Our team works closely with you to understand your project goals, requirements, and specifications. Whether it's modifying an existing design or creating a completely new one, we provide expert guidance and collaborate with you throughout the process. We offer a wide range of materials, finishes, and dimensional options to ensure that the final product is tailored to your exact specifications.

Timely Delivery:

We recognize the importance of timely delivery in the fast-paced manufacturing landscape. Our streamlined processes, efficient workflows, and optimized scheduling ensure that your precision parts are delivered on time, without compromising on quality. We prioritize clear communication, project management, and efficient production planning to meet your project deadlines. You can rely on us as a dependable partner that respects your time and understands the impact of timely delivery on your business.

Additional processes

Tumbling and Vibratory Finishing

· Tumbling: A process where parts are placed in a rotating drum with abrasives or polishing media. This process is ideal for deburring, polishing, and rounding edges of small parts.

· Vibratory Finishing: Similar to tumbling, but instead of rotation, parts are vibrated with media in a bowl or trough. This is used for deburring and polishing parts in bulk, especially small and delicate components.

Advantage: Ideal for deburring, polishing, and surface preparation for high-precision parts with intricate geometries or sharp edges.