产品描述

300Bar 陶瓷凹膜压力模组是一款技术精湛的压力传感设备。它以高品质陶瓷为基材,经精细工艺打造出独特的凹膜构造,能精准感知并测量高达 300Bar 的压力。具备出色的抗腐蚀与抗磨损性能,无论是化工领域的腐蚀性环境,还是机械制造中的高强度压力冲击,都能稳定工作。其内部传感元件高度灵敏,可迅速将压力变化转化为精确的电信号,为工业自动化控制、汽车性能监测等众多行业提供可靠的压力数据支持,有效保障系统的安全稳定运行并助力优化整体性能。

产品参数

| 压力量程 | 2Bar,5Bar,10Bar,16Bar,20Bar,30Bar,50Bar,100Bar,200Bar,300Bar,400Bar,600Bar |

| 压力类型 | 表压/绝压/密封压 |

| 工作电压 | 5.0V/3.3V/5-30V DC工作电压可根据客户需求选择 |

| 工作电流 | <10mA |

| 工作温度 | -40~135°C |

| 过载压力 | 2倍压力量程 |

| 爆破压力 | 3倍压力量程 |

| 输出方式 | 4-20mA/0.5-4.5V/0-2.5V/0-5V/0-10V/比例电压/12C/SENT/SPI可选 |

| 综合输出精度 | 0-85℃<1%FS;-40~135℃<2.0%FS; |

| 非线性 | 0.25%FS Max. |

| 迟滞&重复性 | ±0.25%FS Max. |

| 响应时间 | <10mS |

| 工作寿命 | >200万次0-满量程-0压力循环@2-5Hz,15-35°C |

| 长期稳定性零点@25±5°C | <0.20%FSO(无时间累计) |

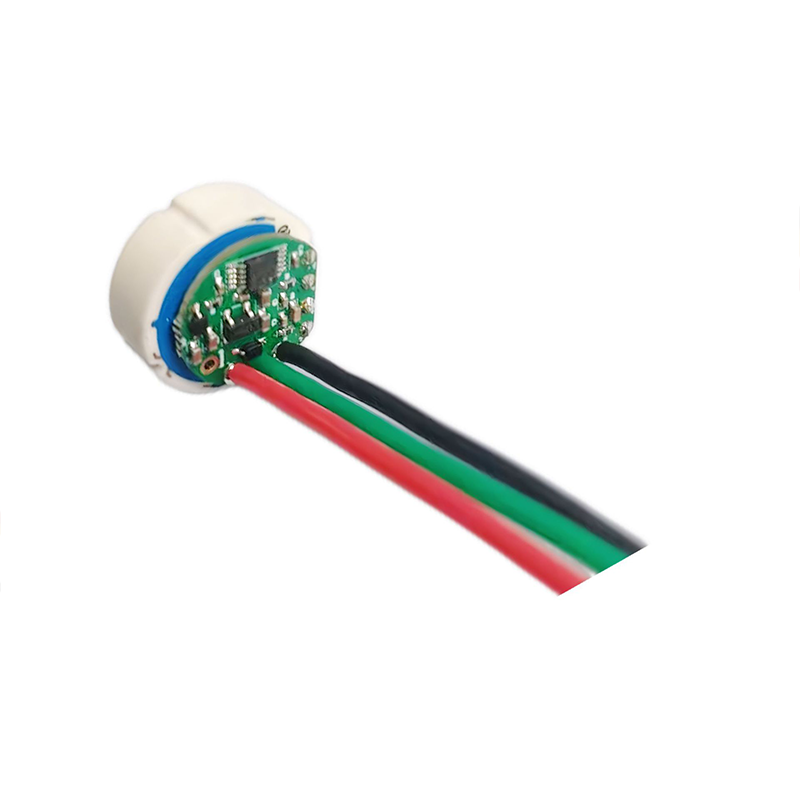

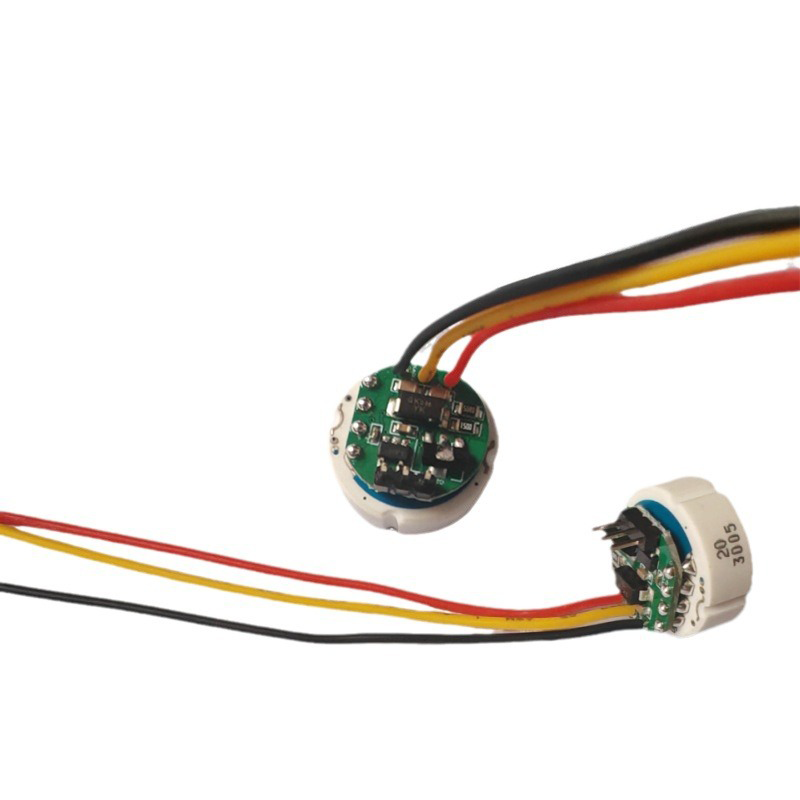

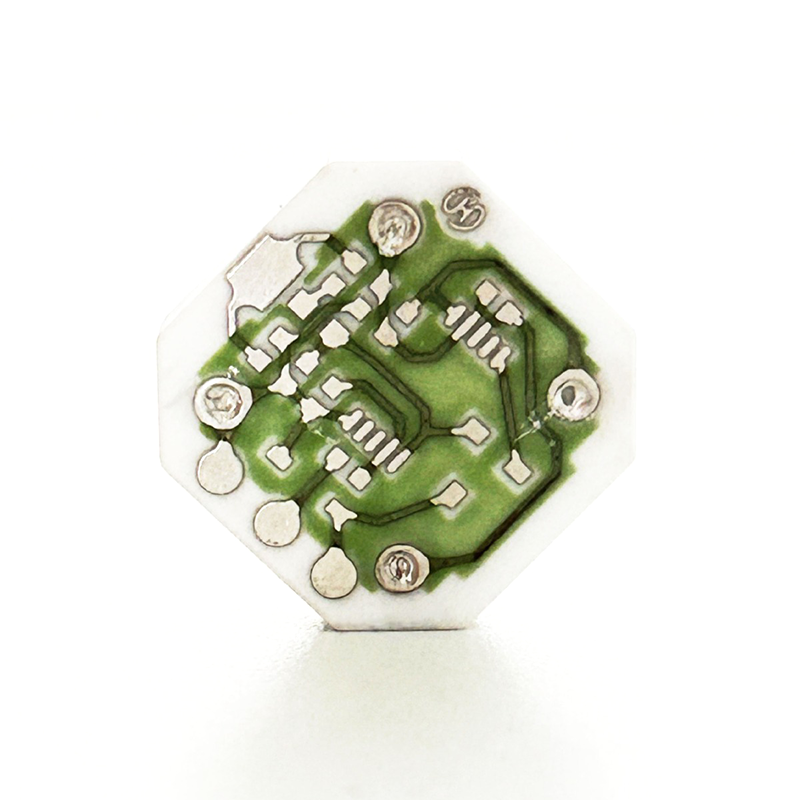

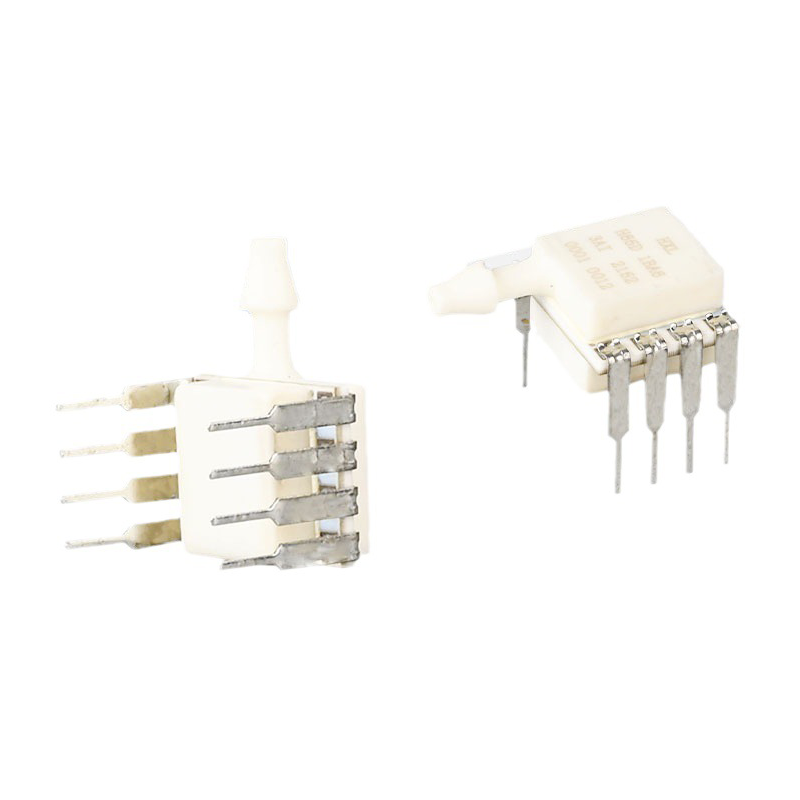

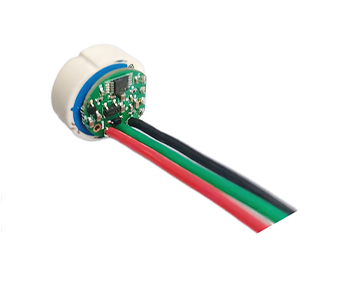

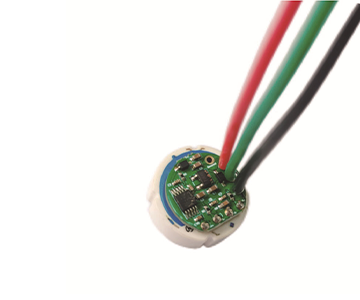

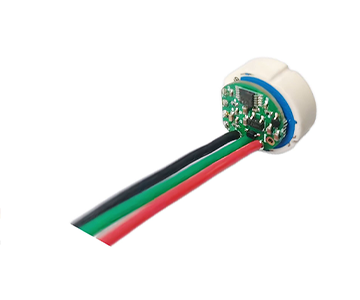

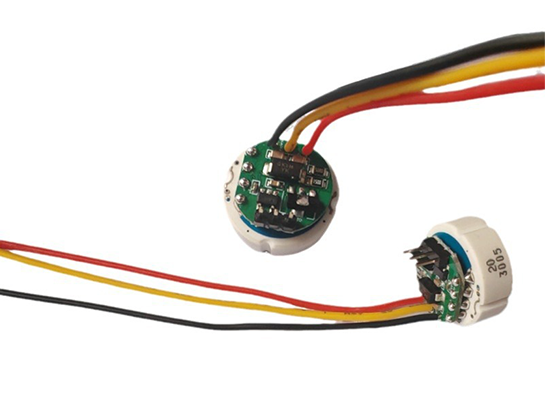

产品展示

- 陶瓷凹膜压力模组具备卓越的抗腐蚀性能,其陶瓷材质化学性质稳定,可耐受酸碱等强腐蚀性介质侵蚀,在恶劣化学环境中也能长久使用。

- 陶瓷凹膜压力模组拥有卓越的抗磨损性能,特殊陶瓷结构使其硬度高且表面光滑,面对频繁摩擦和冲击依然能保持良好状态,减少损耗。

- 陶瓷凹膜压力模组具有款式多样支持定制的特点,无论是尺寸大小、形状样式,还是内部结构细节,均可根据客户实际需求进行个性化设计与定制生产。

- 陶瓷凹膜压力模组具有高灵敏度的特点,能够敏锐地感知微小的压力变化,哪怕是极其细微的压力波动也能迅速捕捉并转化为精准的信号输出,为精密测量与精准控制提供有力支持。

- 该模组具备高精度特性,通过先进的制造工艺与严格的质量把控,其压力测量误差被控制在极小范围内,无论是在科研实验的数据采集,还是在工业生产的关键参数监测中,都能确保结果的高度精确性。

- 陶瓷凹膜压力模组呈现出高稳定性,无论是在温度、湿度等环境因素变化较大的情况下,还是在长时间连续工作的压力之下,依然能够稳定运行,保持测量性能的一致性与可靠性,减少因设备不稳定带来的误差与故障风险。

- 其体积小巧易封装的特点也十分突出,紧凑的结构设计使得它能够轻松适配于各种小型化、集成化的设备与系统中,在有限的空间内实现高效的压力测量功能,并且方便进行封装整合,降低了整体设备的体积与复杂度。

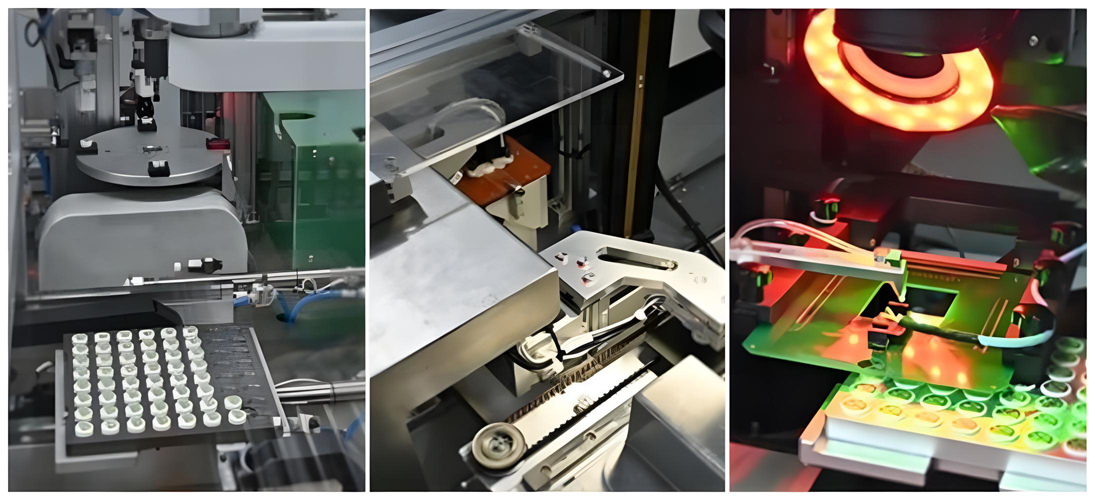

品控

我们秉持着对品质的极致追求,构建了全方位、多层次的严格品控体系。从原材料的精挑细选,严格甄别每一批次的质量与特性,到生产环节中运用先进工艺与精密设备,遵循标准化流程并设置多道检测关卡,实时监控每一个细微的生产步骤,再到成品阶段进行全面且深入的性能检测,模拟各种复杂环境与使用场景,不放过任何一个可能影响品质的因素,以确保每一件产品都能达到高精度、高稳定性、高可靠性的卓越标准,为消费者提供值得信赖的优质商品与服务。

应用案例

陶瓷凹膜压力模组在航空航天领域的飞行器燃油压力监测系统中精准运行,为飞行安全提供关键数据保障;于化工生产的高压反应釜内压力测量环节稳定发挥作用,助力化学反应精准控制;在汽车发动机油压检测方面表现出色,优化汽车动力性能与可靠性

服务

- 专业工程师咨询无忧:专业工程师团队凭借深厚知识与丰富经验,随时为您答疑解惑,从产品技术细节到应用方案规划,提供全方位咨询服务,让您毫无困扰。

- 两年质保品质保障:长达两年的质保期彰显对产品质量的高度自信,期间若遇质量问题,我们将迅速响应并妥善处理,为您免去后顾之忧。

- 源头工厂:作为源头工厂,我们掌控生产全流程,从优质原料采购到精细加工制造,确保产品质量过硬且性价比超高。

- 支持定制:根据您的特殊需求,无论是独特的尺寸规格还是个性化的性能要求,我们都能量身定制,打造专属您的陶瓷凹膜压力模组。