产品描述

橡胶履带是一种用于车辆或机械行走装置的部件,主要由橡胶和骨架材料构成。在工作过程中,橡胶履带与地面以及其他部件之间产生的噪音要比钢制履带小很多。这是因为橡胶具有一定的弹性,可以缓冲部件之间的碰撞和摩擦产生的声音。橡胶履带是现代农业中广泛使用的设备。它可以在潮湿、泥泞的农田里正常作业,而且不会像轮式拖拉机那样容易陷入泥坑。同时,橡胶履带对土壤的压实程度相对较小,有利于保护土壤的结构,促进农作物的生长。

产品参数

| 履带规格(宽度x节距) TrackSize (WidthxPitch) | 内轨宽度 InnerGuide Width(A) | 外轨宽度 OuterGuide Width(B) | 齿内高度 Inner Height(C) | 齿外高度 Outer Height(D) | 履带厚度 Track Thickness(E) | 花纹类型 Lug Pattern | 支承类型 Gude Type | 最大机重MaxMachine Weight(kg) | 备 注 Remarks |

|---|---|---|---|---|---|---|---|---|---|

| 180x72 | 23 | 64 | 29 | 26.5 | 59 | B | A | 1000 | |

| 180x72K | 23 | 65.5 | 29 | 27 | 65 | B | C | 1200 | AVT |

| 190x72 | 23 | 66 | 28.5 | 26 | 67 | B | A | 1300 | |

| 200x72 | 23 | 66 | 29 | 26 | 64 | B | A | 1300 | |

| 200x72K | 23 | 65.5 | 29 | 27 | 65 | B | C | 1400 | AVT |

| 230x72 | 24 | 74 | 29 | 27 | 70 | B/I | A | 1600 | |

| 230x72K | 23 | 71 | 29 | 28 | 70 | B | C | 1800 | AVT |

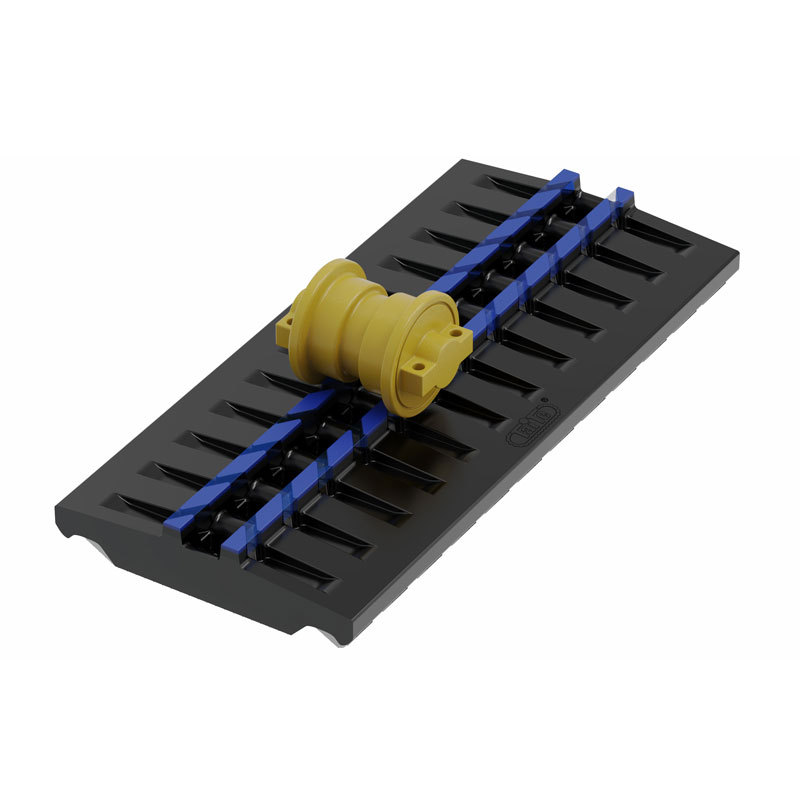

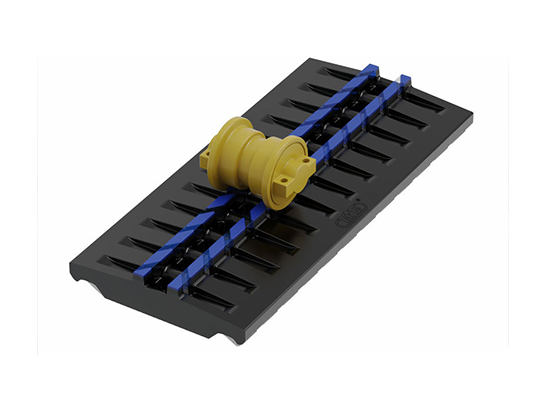

产品展示

良好的机动性:橡胶履带车辆相对于传统的钢制履带车辆,具有更好的机动性。因为橡胶履带质地相对较软,对地面的压力分布更加均匀,在一些对地面承载能力要求较高的场地,如室内地面、草坪等,橡胶履带能够减少对地面的破坏,并且可以灵活地转弯和操作。

较低的噪音:在工作过程中,橡胶履带与地面以及其他部件之间产生的噪音要比钢制履带小很多。这是因为橡胶具有一定的弹性,可以缓冲部件之间的碰撞和摩擦产生的声音。

高舒适性:由于橡胶履带的弹性特性,其装备的车辆在行驶过程中能够吸收一部分来自地面的震动。这使得驾驶人员和乘坐人员在车内感受到的颠簸较小,提高了乘坐的舒适性。就像在越野车上安装高性能的橡胶减震履带后,即使在崎岖不平的山路上行驶,车内人员也不会感到过于强烈的震动。

应用案例

泰特橡胶以技术为本,积极拓展新的业务和领域。我们不断探索橡胶性能的极限,让履带适应更快的速度,更大的机重,更极端的工况,这在军工领域尤为重要。在先进农机领域,我们研发的大功率农业车辆履带系统,能大大增强车辆的通过性,降低接地比压,防止土地板结。

公司介绍

泰特橡胶是专业的工程机械和农业机械底盘橡胶零部件制造商。我们致力于为客户提供专业的技术服务、优质的产品和及时周到的服务,协助他们在各自的领域取得成就。

对OEM客户,泰特优秀的技术团队提供一站式的技术支持。客户既可以选用我们现有的规格,也可以按需求定制。在设计过程中我们与客户的技术团队进行充分交流,根据客户的底盘框架和轮系选型,来设计履带的结构,并根据机器的重量、速度、使用工况设计橡胶配方。这既保证底盘与履带良好的匹配性,更保证了产品性能和质量的稳定可靠。

服务

- 定制化设计:根据不同客户的需求,研发和设计特定规格、性能的橡胶履带。比如,为适应不同型号的工程机械、农业机械等,设计出不同尺寸、花纹、强度的橡胶履带,满足客户在各种工况下的使用要求。

- 质量控制:建立严格的质量检测体系,从原材料采购、生产加工到成品出厂,进行全程质量监控。例如,检测橡胶的硬度、拉伸强度、耐磨性能,以及骨架材料的强度、韧性等指标,确保产品符合相关标准和客户的质量期望。