Product Description

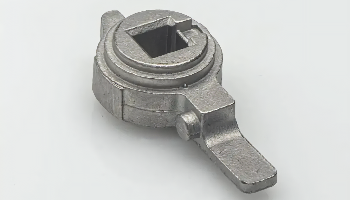

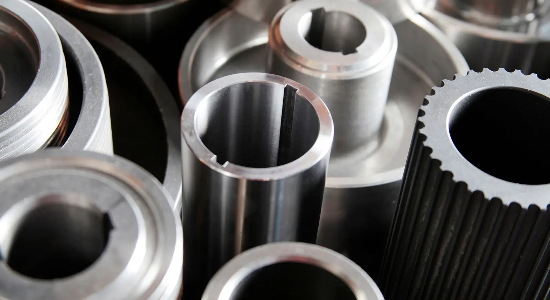

We are a leading manufacturer specializing in providing high-quality, customized OEM casting parts. With advanced manufacturing processes and state-of-the-art technology, we cater to a wide range of industries, delivering precision-engineered components tailored to meet specific customer requirements. Our expertise in casting allows us to offer solutions that ensure durability, performance, and cost-effectiveness. Whether you need small or large production runs, we are committed to delivering products that align with your exact specifications, while maintaining the highest standards of quality and reliability.

We offer Custom Design Die Casting Parts Services, specializing in the creation of high-precision, high-quality metal components tailored to meet your specific needs. Our expertise in casting allows us to offer solutions that ensure durability, performance, and cost-effectiveness. Whether it's for small-scale or large-volume production, we work closely with you to ensure each part meets the highest standards of performance, durability, and efficiency. With expertise in aluminum, zinc, magnesium, and copper alloys, we provide comprehensive solutions, including prototyping, machining, surface finishing, and quality control. Whether for automotive, aerospace, electronics, or consumer goods, our custom die casting services deliver reliable, cost-effective solutions for high-volume production with exceptional strength and accuracy.

Product parameters

| Description | Densen Customized Engine Housing Clay Sand Casting High Difficult Thin Walled Grey Iron Parts with Precision CNC |

| Type | OEM |

| Application | Industrial Equipment,Industry system |

| Processing | Casting+heating Treatment |

| Material | Carbon steel,Alloy steel |

| Weight Ranges | 0.05-100kg |

| Tolernace | Controlled by ISO 8006 CT4-6 |

| Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

| Quality Control | Material, Dimension,Performance,inside defects,Balance test |

| Standard | ASTM,DIN,JIS,ISO,GB standards |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

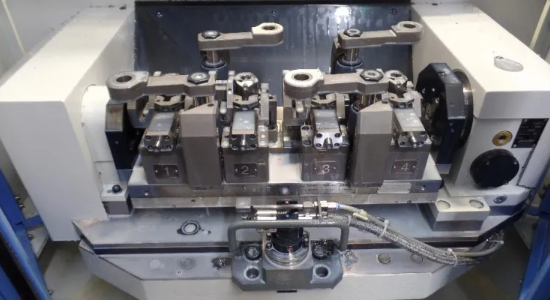

CNC Machining

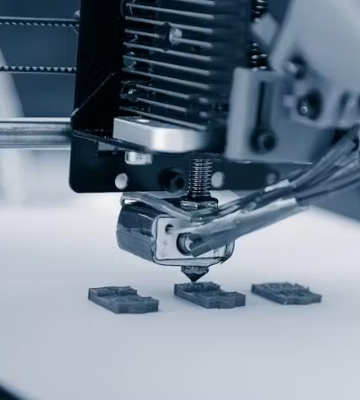

3D Printing

Surface Treatment

Material

Stainless steel

Aluminum

Titanium

Brass

Additional processes

In addition to the core casting process, several secondary processes are often used to enhance the quality, functionality, and appearance of casting parts. These include:

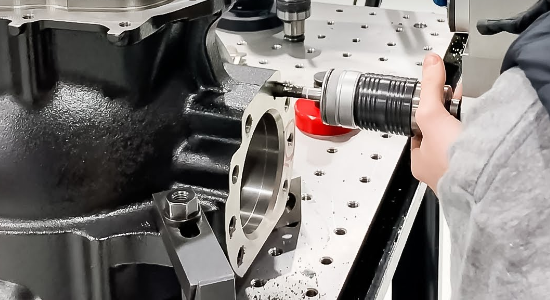

Machining: After the casting process, many parts require additional machining to achieve precise dimensions, smooth surfaces, and tight tolerances. Using advanced techniques such as CNC milling, turning, and grinding, we refine the cast components to meet the exact specifications required for your application. These machining processes ensure that the parts fit perfectly within the assembly, function optimally, and maintain high levels of performance and durability. Whether it’s fine-tuning intricate features or achieving a flawless finish, our machining services provide the precision necessary for high-quality, reliable casting parts.

Heat Treatment: Heat treatment is a critical process used to enhance the mechanical properties of cast parts, including strength, hardness, and durability. By carefully heating and cooling the cast components in controlled environments, we can adjust their microstructure to achieve the desired performance characteristics. This process not only improves the overall quality of the parts but also ensures they are more resistant to wear, corrosion, and stress, making them ideal for demanding applications in various industries. Whether you're seeking improved toughness, increased hardness, or better fatigue resistance, our heat treatment services provide the optimal solution for your casting needs.

Surface Finishing: Surface finishing encompasses a range of techniques designed to improve both the appearance and performance of casting parts. These processes include polishing, grinding, sandblasting, coating, and plating, each tailored to meet specific functional and aesthetic requirements. By refining the surface texture, surface finishing can enhance wear resistance, reduce friction, improve corrosion protection, and create a more visually appealing finish. Whether you need a smooth, polished surface for high-end aesthetics or a textured finish for added grip and durability, our surface finishing services help optimize your casting parts for both functionality and appearance, including:

- Polishing: Achieving a smooth, shiny finish.

- Anodizing: Enhancing corrosion resistance and appearance, often used for aluminum parts.

- Powder Coating: Applying a protective coating for better corrosion resistance and aesthetics.

- Painting: Providing a colored finish to improve both protection and visual appeal.

Assembly: In some cases, casting parts are assembled with other components, such as fasteners or inserts, to create a complete product or subassembly.

These additional processes ensure that casting parts meet the specific performance, aesthetic, and durability requirements for their intended applications.