Product Description

With 11 years of experience in the casting industry, BAC Company has built a strong reputation as a leading provider of high-quality, customized solutions. Our factory is dedicated to delivering top-tier casting products and services that meet the unique requirements of our clients across a wide range of industries. Whether you're looking for standard components or need bespoke, non-standard parts tailored to your specifications, we have the expertise and capabilities to deliver outstanding results.

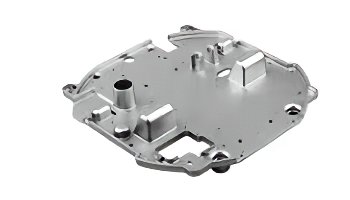

Our Core Capabilities and Services: Precision Casting Expertise: At BAC Company, we specialize in a variety of casting techniques, enabling us to produce a wide range of parts with superior precision and durability. Our experienced team uses the latest technology and processes to manufacture castings that meet the strictest quality standards. We handle both ferrous and non-ferrous materials, including steel, aluminum, brass, and cast iron, ensuring flexibility to cater to your specific project needs.

Product parameters

| Product Name | communication product |

| Material | ADC12 |

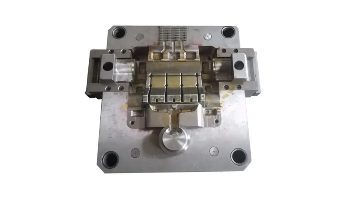

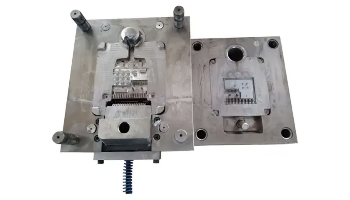

| Process | Die casting |

| Surface Treatment | Electroplating |

| Application | All areas |

| Color | As Customer Request |

| Dimension | Customized |

| Packaging | EPE foam/Anti-Rust Paper/Stretch Film/Plastic bag +Carton |

| Drawing Format | PRO/E, Auto CAD, Solid Works , UG, CAD/CAM/CAE, PDF |

| Lead Time | 15-20days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Material

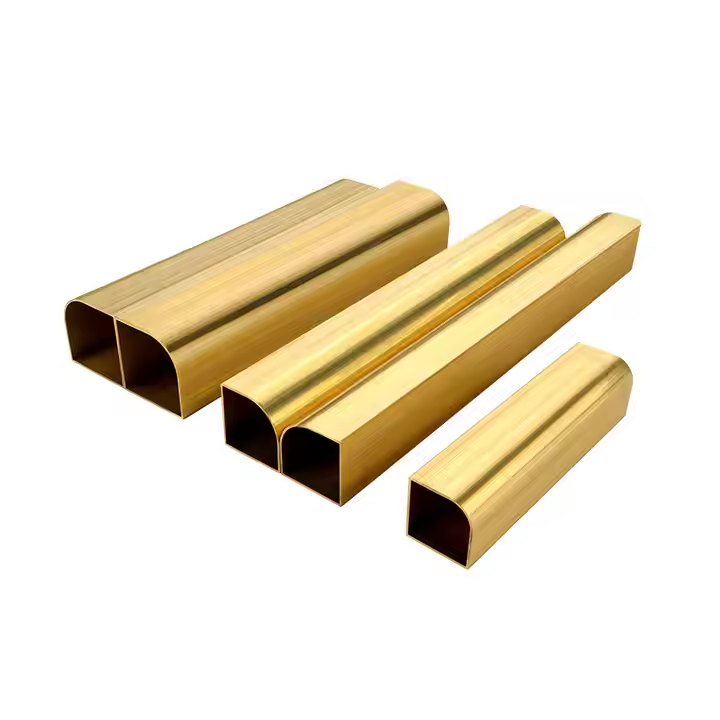

Brass

Copper

Aluminum

Special steel

Processing capability

At BAC Company, we pride ourselves on our robust production capacity, which allows us to efficiently handle a wide range of manufacturing needs, from small custom orders to large-scale industrial production. With 11 years of experience in the casting industry, we have developed the expertise, technology, and infrastructure to meet diverse client demands, ensuring consistent quality and timely delivery.

Flexibility in Small Batch and Custom Orders: While we excel in large-scale production, we also understand the importance of flexibility when it comes to small batch and custom manufacturing. BAC Company specializes in producing non-standard, custom-designed parts for clients in need of unique components or prototypes.

- Extensive Capacity: From high-volume orders to custom, low-volume production, we have the flexibility and capacity to meet a wide range of manufacturing needs.

- Advanced Technology: Our state-of-the-art equipment ensures high-precision casting and machining, while our multi-process capabilities streamline production and reduce lead times.

- Expert Team: With over a decade of experience, our skilled engineers and technicians work closely with you to ensure that every part meets your specifications, regardless of complexity.

- Quality Assurance: We maintain the highest standards of quality control throughout the entire production process, ensuring that every part meets your exact requirements.

Additional processes

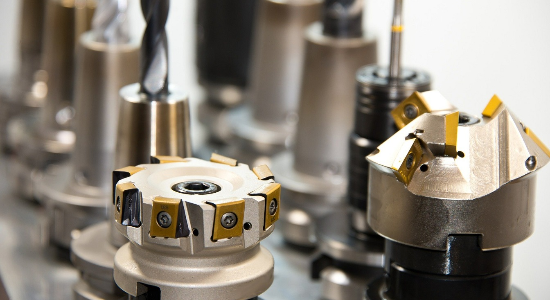

1. CNC Machining: After the casting process, our advanced CNC machining capabilities ensure that your parts achieve the necessary tolerances and finishes. CNC milling, turning, drilling, and tapping are performed to refine your castings into perfectly finished products, with precise dimensions and smooth surfaces.

- Precision Tolerances: Achieve tight tolerances and fine surface finishes, ideal for parts that require exact dimensions and functionality.

- Complex Geometries: Our CNC machining can handle even the most intricate geometries and details that casting alone cannot achieve.

2. Heat Treatment: To enhance the mechanical properties of your castings, we offer heat treatment services that improve hardness, strength, and durability. Heat treatment is ideal for parts that will undergo significant stress or need improved wear resistance.

- Annealing: Reduces internal stresses and softens the material for improved machinability.

- Quenching & Tempering: Increases the hardness and toughness of the metal, providing improved wear resistance and strength.

- Normalizing: Ensures uniform hardness and eliminates inconsistencies in the material structure.

3. Packaging and Shipping Services: To ensure that your parts arrive at their destination in perfect condition, we provide customized packaging solutions. Depending on your needs, we offer:

- Protective Wrapping: To prevent scratches, dents, or damage during transportation.

- Crating & Palletizing: For larger or bulk orders, we use custom crates and pallets to securely ship parts to your location.

- Global Shipping: With our logistics network, we can deliver parts on time, anywhere in the world.