Product Description

Lead screw diameter: The "40" in the model indicates that the lead screw diameter is 40mm. This size indicates the overall size and strength of the ball screw, and its compatibility with other components needs to be considered when installed in the equipment, and it also determines the range of loads that the ball screw can withstand.

Lead: 05 indicates that the lead is 5mm. Lead refers to the screw rotation once, the nut along the screw axis to move the distance. The smaller lead makes the ball screw suitable for applications where high precision positioning is required, enabling finer displacement control.

Product parameters

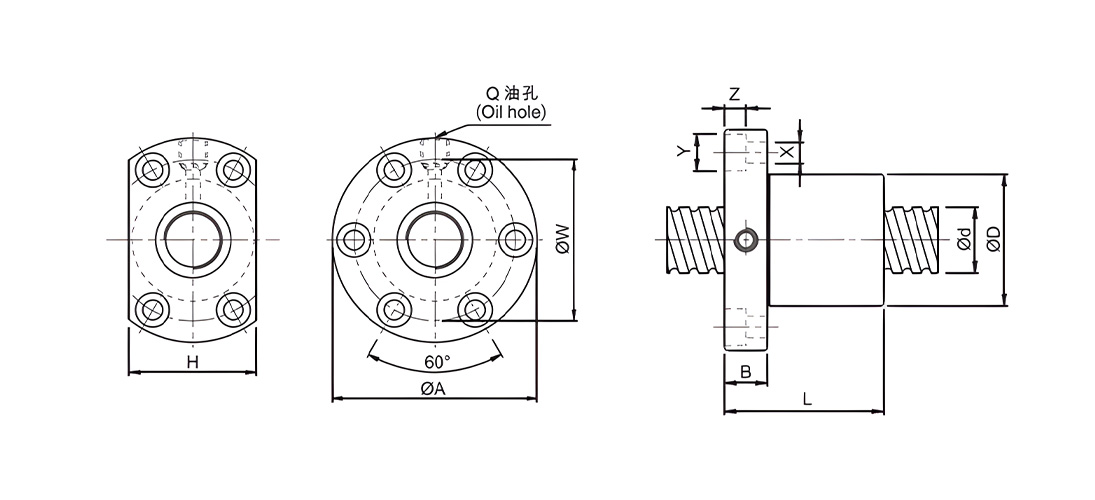

| Nominal type | Shaft diameter | lead | Pearl diameter | Nut size | Dynamic rated load | Static rated load | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d | l | Da | D | A | E | B | L | W | H | X | Q | n | Ca | Coa | |

| SFE01616-3.6 | 16 | 16 | 2.778 | 32 | 53 | 10.1 | 10 | 45 | 42 | 34 | 4.5 | M6x1 | 1.8x2 | 1073 | 2551 |

| SFE02020-3.6 | 20 | 20 | 3.175 | 39 | 62 | 11.5 | 10 | 55 | 50 | 41 | 5.5 | M6x1 | 1.8x2 | 1387 | 3515 |

| SFE02525-3.6 | 25 | 25 | 3.969 | 47 | 74 | 13 | 12 | 57 | 60 | 49 | 6.6 | M6x1 | 1.8x2 | 2074 | 5494 |

| SFE03232-3.6 | 40 | 32 | 4.762 | 58 | 92 | 16 | 12 | 82 | 74 | 60 | 9 | M6x1 | 1.8x2 | 3021 | 8690 |

| SFE04040-3.6 | 32 | 40 | 6.35 | 73 | 114 | 19 | 15 | 100 | 93 | 75 | 11 | M6x1 | 1.8x2 | 4831 | 14062 |

| SFE05050-3.6 | 50 | 50 | 7.938 | 90 | 135 | 21.5 | 20 | 125 | 112 | 92 | 14 | M6x1 | 1.8x2 | 7220 | 21974 |

Product Display

Positioning accuracy:

SFIR4005 ball screw has high positioning accuracy. Through precision machining processes such as grinding and grinding, positioning accuracy can be controlled in the micron level. In the application of precision machine tools, such as CNC milling machines, it can precisely control the position of the tool, so as to process high-precision parts, such as aerospace parts, precision molds, etc.

Repeated positioning accuracy:

The ball screw also maintains good accuracy during repeated movements. For automated equipment, such as automated assembly lines, it can repeatedly place parts precisely in the designated position, ensuring the stability of the production process and the consistency of product quality.

Directional load capacity:

It has a strong axial load capacity. This is because the ball rolls between the raceway of the lead screw and the nut, which can effectively disperse the axial force. In practical applications, it can be used to drive parts that need to withstand large axial forces, such as the workbench of large machine tools, lifting devices of heavy machinery, etc.

Dynamic and static load capacity:

In terms of dynamic load, it can adapt to changes in load to ensure stable transmission of power during movement. Its static load capacity can also ensure that the load is reliably supported in the static state to prevent subsidence or displacement.

Motion smoothness:

The ball screw movement is very smooth. This is because the rolling friction coefficient between the ball and the raceway is small, and the circular motion design of the ball is reasonable, which avoids the crawling phenomenon of the traditional lead screw. In precision equipment, this smooth movement can reduce vibration and noise, which is conducive to improving the service life and working accuracy of the equipment.

SFI series specification size

Quality Control

Ball screw production adhere to strict quality control system. In terms of raw materials, we select global quality suppliers, and strictly inspect alloy steel, ball and other materials with the help of spectral analyzer and hardness tester. In the production, the use of advanced automation equipment and technology, CNC grinding machine to ensure the processing accuracy, through real-time data monitoring and optimization of process parameters, and multi-node "self-check, mutual check, special inspection". When testing the finished product, a comprehensive performance test such as lead accuracy, positioning and repeated positioning accuracy, rated load, rigidity, etc. is carried out on a professional platform, and appearance and packaging are also checked. Follow international standards such as ISO 9001 certification, establish quality feedback mechanism, collect customer opinions, analyze quality data, continuous improvement, win market reputation with excellent quality, and provide reliable transmission solutions for precision machinery industry.

Application Cases

Automation equipment: used in linear modules, robotic arms and other equipment for automated production lines. It can realize the functions of accurate assembly of parts and accurate conveying of materials, and improve the work efficiency and accuracy of automation equipment.

Precision instruments: In optical instruments, electron microscopes, precision measuring equipment and other precision instruments, as a fine-tuning mechanism or displacement driving components, to ensure the high-precision operation of the instrument.

Company Introduction

Zhejiang Jianzhuang Transmission Technology Co., Ltd.

The company focuses on the industry for more than ten years, specializing in the production of ball screw, grinding screw, nut, linear guide, roller guide, slider, module support base and other products manufacturers, is a research and development, production, sales, trade as one of the modern enterprise, with a complete and scientific quality management system.

The company's products are widely used in various high-tech industries: CNC machine tools, automation, laser, medical equipment, textile woodworking and electronic products.

Zhejiang Robust transmission is the second production base of SHAC, the brand comes from quality, integrity to win trust,17 years of craftsmanship only for the screw and guide rail more durable, more precise and more professional, to meet the needs of the market. Welcome friends at home and abroad to visit, guidance and business negotiations!

Service

Precision ball screw manufacturer service: the whole intimate companionship, professional casting excellence

Before sales, senior experts customize the selection scheme and application blueprint according to your needs, and in-depth consultation helps decision-making. During the sale, the dedicated ambassador follows up the order throughout the process, and works with top logistics for efficient delivery, with detailed installation and commissioning guidelines and remote guidance. After sale, 24-hour hotline response, or remote quick problem solving, regular return visit to optimize service. Provide systematic technical training, integrating theory and practice. Value-added services cover custom design, product upgrading and overall equipment optimization, and join hands to create industrial brilliance.