Product Description

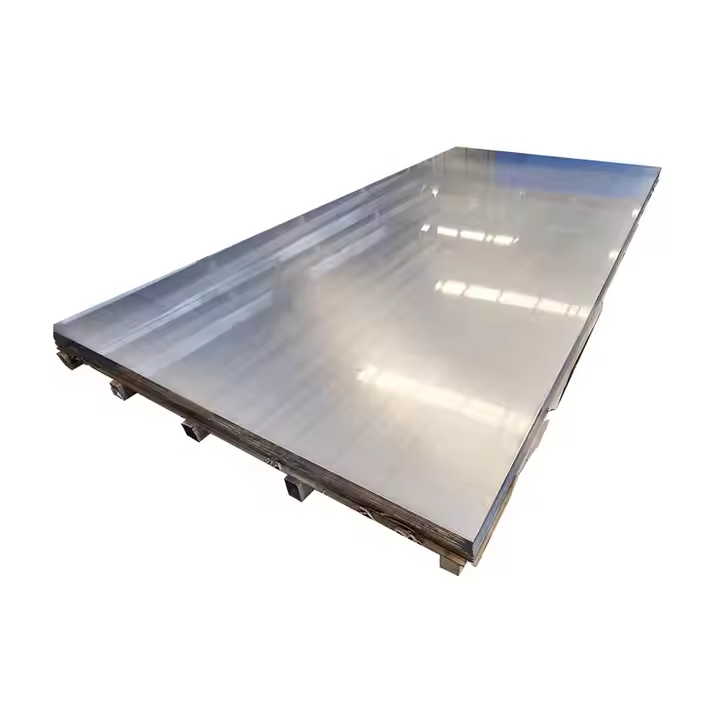

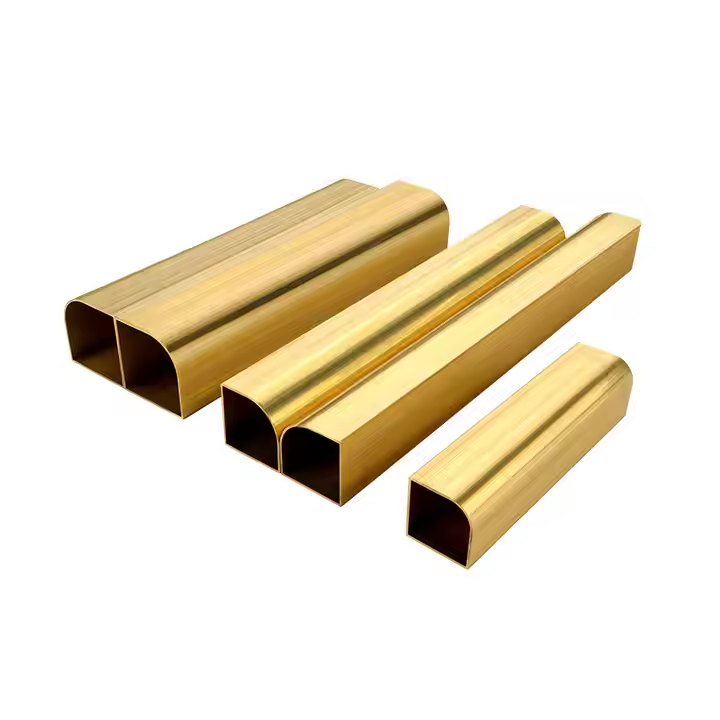

High-Quality Materials: We are committed to providing only the best materials for our castings, sourced from trusted suppliers. Our factory handles a broad range of metals and alloys, including but not limited to:

- Steel (carbon steel, stainless steel, alloy steel)

- Aluminum (casting alloys, heat-treated aluminum)

- Brass and Bronze (for corrosion-resistant applications)

- Iron (gray iron, ductile iron)

Whether you need lightweight, high-strength materials or corrosion-resistant options, we have the materials and expertise to meet your needs.

Product parameters

| Item | Parameters |

|---|---|

| Specification | Customized,customer required,customer's drawings |

| Material | Carbon steel,Stainless steel,Alloy steel,Heat resistant steel,Brass,Copper, etc. |

| Application | Automobile, agricultural machinery, furniture, construction, home appliances, electronics. |

| Process | Forging |

| Machining | Punch, Press, Spinning lathe, Precision punch |

| Heat treatment | Quench and tempering,Carburizing,Nitriding,Induction hardening,Normalizing, |

| Unit weight | 5g-300kg |

| Certificate | KQA-Q172962 KQA-TS150225 KQA-E23907 |

| Finish | Polishing,Powder coating,Painting,Nickel plating,Chrome plating,Hot galvanize,Galvanizing, Electrophoresis,Anodizing |

| Service | Weekly report,Key node report,Any questions will be answered within 24 hours. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Material

Aluminum

Brass

Special steel

Steel

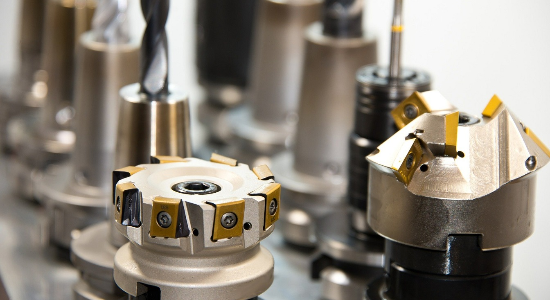

Processing capability

Multi-Process Manufacturing Capabilities: BAC Company has integrated several key processes into our production workflow, allowing us to produce fully finished parts ready for use in your final product. This integrated approach enhances our production capacity, enabling us to offer a one-stop solution for all your manufacturing needs.

- Casting: With a wide range of casting techniques including sand casting, die casting, investment casting, and gravity casting, we are able to create highly detailed, durable parts for diverse applications.

- Secondary Processes: We also provide essential secondary processes, including CNC machining, heat treatment, surface finishing (such as polishing, coating, and sandblasting), welding, and assembly. This allows us to produce parts that are not only accurate but also meet your specific functional and aesthetic requirements.

- Customization: Our in-house design team works with clients to adapt and refine their designs, ensuring that every part is produced to exact specifications, regardless of complexity.

Material Handling Capacity: We have the capacity to handle a wide range of materials, from traditional metals like cast iron and steel to high-performance alloys such as aluminum and brass. We are equipped to work with both ferrous and non-ferrous metals, and we ensure that each material is processed according to its specific characteristics and requirements.

- Wide Range of Materials: Our capabilities include working with different grades of steel, aluminum, brass, bronze, and cast iron, among others. We can provide materials with specific properties such as corrosion resistance, heat resistance, and high tensile strength.

- Custom Alloys: We also specialize in producing parts with custom alloy compositions, ensuring that the material properties are perfectly suited to your application.

Additional processes

At BAC Company, we understand that precision casting is just the beginning of creating high-quality components. To ensure your parts meet the exact functional, aesthetic, and durability standards, we offer a comprehensive range of additional processes. These services provide finishing, strengthening, and customization options that enhance the quality, performance, and appearance of the cast parts.

1. CNC Machining: After the casting process, our advanced CNC machining capabilities ensure that your parts achieve the necessary tolerances and finishes. CNC milling, turning, drilling, and tapping are performed to refine your castings into perfectly finished products, with precise dimensions and smooth surfaces.

- Precision Tolerances: Achieve tight tolerances and fine surface finishes, ideal for parts that require exact dimensions and functionality.

- Complex Geometries: Our CNC machining can handle even the most intricate geometries and details that casting alone cannot achieve.

2. Non-Destructive Testing (NDT): To ensure the integrity of your castings, we offer various non-destructive testing methods that help identify internal or surface defects without damaging the parts. These tests are essential for ensuring the reliability and quality of the final product.

- Ultrasonic Testing: Detects internal flaws, such as voids or cracks, ensuring that parts are structurally sound.

- X-Ray Inspection: Provides detailed insight into the internal structure of the casting, identifying issues such as air pockets or inclusions.

- Magnetic Particle Testing (MPT): Ideal for detecting surface and near-surface cracks in ferrous materials.

3. Heat Treatment: To enhance the mechanical properties of your castings, we offer heat treatment services that improve hardness, strength, and durability. Heat treatment is ideal for parts that will undergo significant stress or need improved wear resistance.

- Annealing: Reduces internal stresses and softens the material for improved machinability.

- Quenching & Tempering: Increases the hardness and toughness of the metal, providing improved wear resistance and strength.

- Normalizing: Ensures uniform hardness and eliminates inconsistencies in the material structure.