Product Description

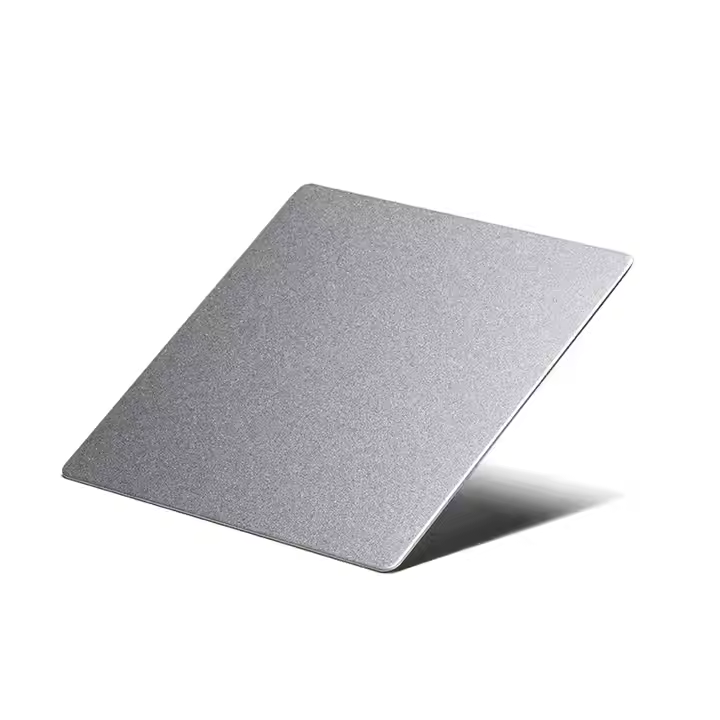

High-precision 5-axis CNC machined parts crafted from stainless steel, brass, aluminum, and titanium. These components are engineered with exceptional accuracy and designed to meet the most demanding specifications across various industries, ensuring long-lasting durability, reliability, and optimal performance in every application.

Product parameters

| List | Details |

|---|---|

| Product name | Brass or Copper CNC Milling Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Model Number | CNC Milling Parts |

| Material | Brass H59, Copper |

| Surface treatment | Chrome Plating, Gold Plating, Polishing, Mirror Polished, Brushed |

| LOGO | Laser engraved or CNC Machined |

| Drawing Format | 2D(PDF/CAD)/3D(IGS/STEP) |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Drilling

Milling

Turning

Material

Silver

Brass

Copper

Quality Control

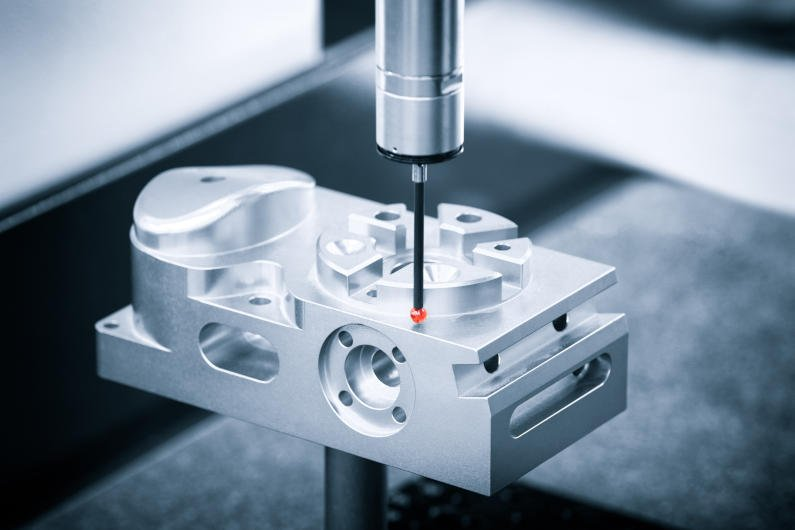

Quality control for 5-Axis CNC Metal Parts ensures precision and consistency at every stage of production. Each component undergoes rigorous inspection using advanced measuring tools like coordinate measuring machines (CMM) to verify dimensions and tolerances. Surface finish, material integrity, and functionality are thoroughly tested to meet strict industry standards. The process includes pre-production material verification, in-process monitoring, and post-production checks to deliver flawless and reliable parts for various applications.

Processing capability

The processing capability of 5-Axis CNC Metal Parts includes advanced machining for complex geometries, tight tolerances, and intricate details. With the ability to machine stainless steel, brass, aluminum, and titanium, it ensures versatility across various materials. The 5-axis technology allows simultaneous movement along multiple axes, enabling precise shaping of contoured surfaces and intricate designs. It supports high-speed operations, reduces manual intervention, and ensures consistent quality for both prototype and large-scale production. This capability meets the demands of industries requiring high precision and exceptional performance.

Additional processes

Additional processes for 5-Axis CNC Metal Parts include surface treatments such as anodizing, powder coating, and polishing to enhance durability and aesthetics. Heat treatment is available to improve material hardness and mechanical properties, while precision grinding and lapping refine surface finishes for optimal functionality. Threading, drilling, and tapping services can be integrated into the machining process for complex assemblies. Additional inspections, such as X-ray or ultrasonic testing, ensure internal integrity. Custom labeling and packaging options are also provided to meet specific client requirements.