Product Description

Choosing ERIK as your stamping custom service provider is the best decision you can make. With hundreds of international partners, we can offer the most competitive prices and the highest quality products tailored to your needs. If you require custom robot parts, our professional team is ready to provide you with the optimal solutions and products to meet your specifications.

Our R&D team works closely with clients to ensure that the products we provide are not only of the highest quality but also incorporate the latest technological advancements. From initial design to final production, we collaborate with you at every step to ensure the end product exceeds your expectations.

Contact us, let ERIK be your trusted partner in stamping solutions. Whether you're looking for custom robot parts or other specialized components, we are here to provide the best products and solutions for your business. Let us help you turn your vision into reality with our high-quality, cost-effective stamping services.

Product parameters

| SHEET METAL FABRICATION | |

|---|---|

| Available Materials | Aluminum,steel,stainless Steel,brass,copper,iron, Etc |

| Surface treatment | All kinds of surface treatments are available, polishing, zinc plating, nickel plating, chrome plating, powder coating, and phosphate coating. |

| Processings | Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding, etc. |

| Tolerance | DIN ISO 2768, 100% QC quality inspection before delivery, can provide quality inspection form. |

| Drawing Accepted | IGS、STP、X_T、DXF、DWG、Pro/E、PDF |

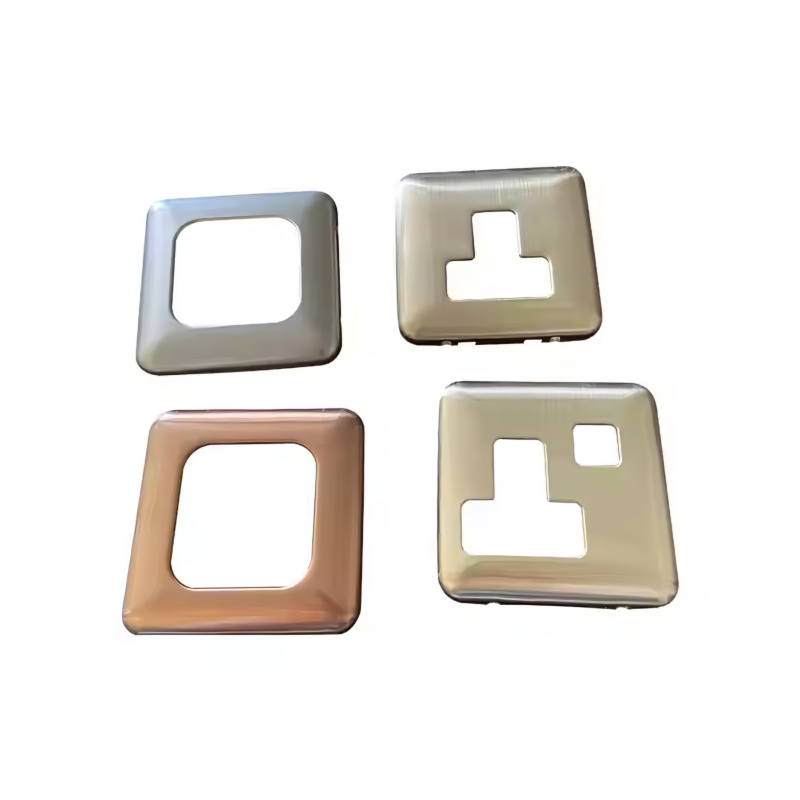

| Sheet Metal Product | Brackets / Enclosures / Sheet metal parts / Frames/ Decorative screen / Stamping parts / Panels / Covers |

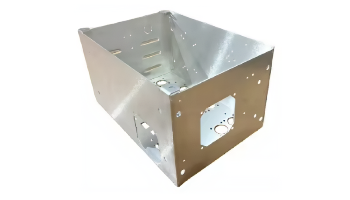

| Enclosures | Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures of all styles, including rackmounts, “U” and “L” shapes, as well as consoles and consolets. |

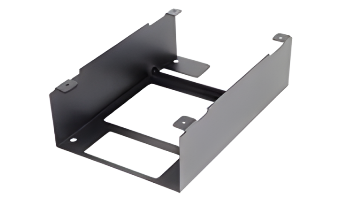

| Chassis | The chassis we fabricate are typically used to house electromechanical controls, from small handheld devices to large industrial testing equipment. All chassis are built to critical dimensions to ensure hole pattern alignment between different parts. |

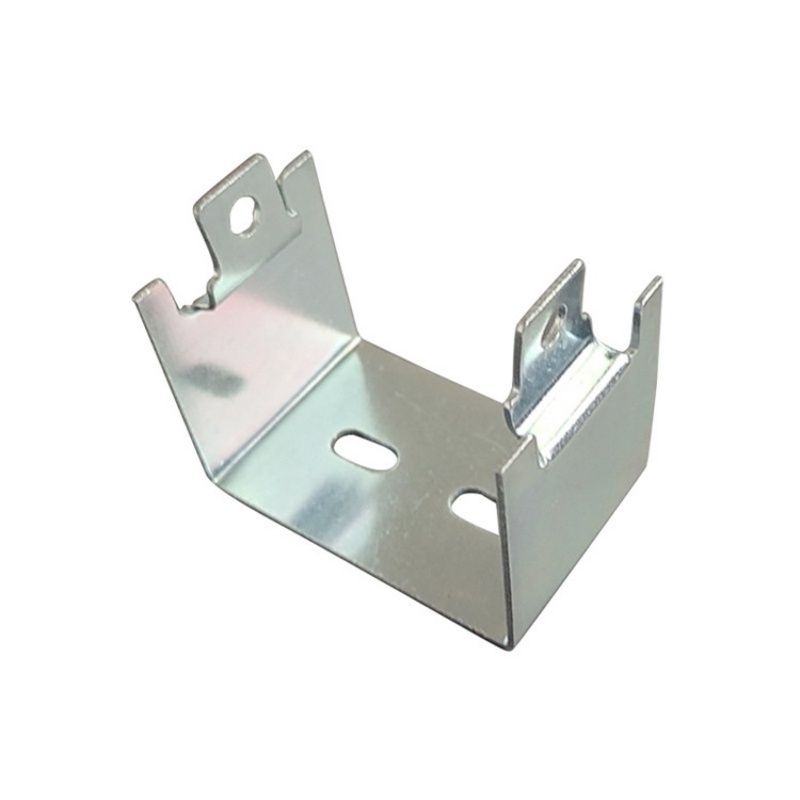

| Brackets | Baijinxin builds custom brackets and miscellaneous sheet metal components, well-suited for either lightweight applications or when a high degree of corrosion-resistance is needed. All hardware and fasteners that are needed can be fully built in. |

| Sample Cost | Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order. |

| Delivery Time | 1-25 days after order with prepayment based on products structure and quantity |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Process Type

Blanking

The process of cutting out a piece from a larger sheet of metal. The cut piece, called a "blank," is separated from the rest of the material. This is often the first step in the production of parts and is used to produce flat, simple shapes.

Embossing

The process of creating raised or recessed designs on the surface of a metal sheet. This is typically done for decorative purposes or for adding features such as logos or patterns.

Notching

The process of cutting small sections from the edge of a metal sheet to produce a notch or indentation. This is often done to create space for subsequent operations or to reduce weight.

Material

Brass

Aluminum

Steel

Stainless steel

Processing capability

Our production facility is designed to handle both simple and highly complex metal parts, offering the flexibility to meet a wide array of customer specifications. With the integration of advanced technologies, we can efficiently produce intricate shapes, deep-drawn components, and parts with exacting dimensional requirements. Whether it’s high-volume production or customized, low-volume runs, we can tailor our processes to meet your specific needs.

We are committed to providing precise and high-quality stamped products by leveraging our extensive expertise in metal forming. Our flexible production processes ensure that we can create parts with complex designs and tight tolerances while maintaining cost-effectiveness and efficiency. The combination of cutting-edge machinery and skilled craftsmanship makes us a reliable partner for producing parts that demand the highest standards of precision.

Additional processes

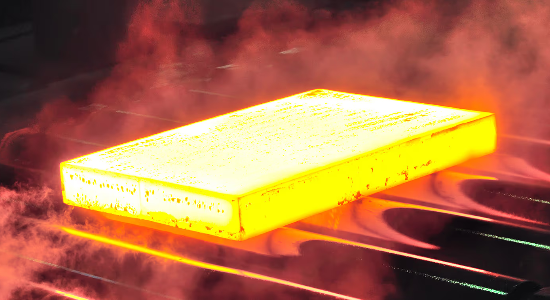

- Heat Treatment: For parts that need enhanced durability, strength, or hardness, heat treatment processes like annealing or tempering can be applied to the stamped metal.

The additional processes allow us to deliver fully customized, high-quality stamped products tailored to meet the exact needs of our customers across a variety of industries.