产品描述

SK - YPC - MX 全贴合工控一体机嵌入式工控工业平板无风扇电容电阻触摸电脑,是一款凝聚先进科技与匠心工艺的工业级智能设备,专为应对复杂多变的工业环境和严苛的应用需求而设计,为各行业自动化进程提供卓越的性能、可靠的稳定性和便捷的操作体验。

产品参数

| 可选 主机配置 | Intel 赛扬J1900、DDR4-8G、SSD-128G | |

| Intel 赛扬 J6412、DDR4-8G、SSD-128G | ||

| Intel 酷睿i3-3217U、DDR4-8G、SSD-128G | ||

| Intel 酷睿i5-3317U、DDR4-8G、SSD-128G | ||

| Intel 酷睿i3-7100U、DDR4-8G、SSD-128G | ||

| Intel 酷睿i5-7200U、DDR4-8G、SSD-128G | ||

| 安卓可选 主机配置 | 安卓A133/2G/16G | |

| 安卓RK3288/2G/16G | ||

| 安卓RK3568/2G/16G | ||

| 安卓3288 2G+64G | ||

| 安卓3399 4G+32G | ||

| 安卓配置主机PK | |||

|---|---|---|---|

| CPU型号 | RK3288 四核 | RK3568 四核 | RK3399 六核 |

| 架构 | CORTEX-A17 | CORTEX-A55 | 双核CORTEX-A72 + 四核CORTEX-A53 |

| 主频 | 1.8GHZ | 2.0GHZ | 1.8GHZ |

| 安卓系统 | 安卓 5.1/6.0/ 7.1/8.1 | 安卓11 | 安卓 7.1/8.1/9.0 |

| 跑分 | 75990分 | 128342分 | 97558分 |

| 新版7代(i3-7100u) | |||

|---|---|---|---|

| 名称 | 参数 | 名称 | 参数 |

| 运行系统 | Windows10 | 主频 | 2.40GHz |

| 最高睿频 | 2.40GHz | 内核数 | 2核 |

| 线程数 | 4-线程 | 核心代号 | Kaby Lake |

| GPU型号 | IntelHD Graphics 620 | CPU功耗 | 10W |

产品展示

极致显示效果

运用先进的全贴合工艺,将电容电阻触摸面板与高分辨率显示屏紧密融合,消除了层间空气间隙,极大地减少了光线反射与折射损耗。这使得屏幕透光率显著提升,呈现出前所未有的清晰、鲜艳、逼真的图像与文字。无论是精细的工业设计图纸、复杂的工艺流程监控画面,还是海量的生产数据图表,都能以最精准、生动的形式展现在操作人员眼前,确保在任何光线条件下,信息读取都毫无障碍,为工业生产决策提供了可靠的视觉依据。

超敏触控响应

全贴合设计优化了触控信号传输路径,电容与电阻触控技术相得益彰。电容触摸屏幕支持多点触控操作,能够敏锐捕捉手指的细微动作,如轻触、滑动、缩放等,实现与工业控制软件的无缝交互。而电阻触摸屏幕则凭借其独特的压力感应机制,在面对恶劣环境干扰(如灰尘、水滴、油污等)时,依然能稳定准确地响应触控指令。这种双触控技术的结合,为不同工业场景下的操作人员提供了多样化、精准化的交互选择,大大提高了操作效率和设备控制的精准度。

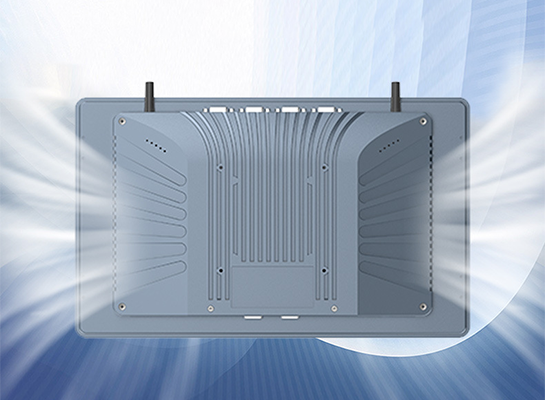

高效散热架构

摒弃传统风扇散热方式,采用独特的被动散热技术。以高品质铝合金打造的机身作为散热主体,内部精心布局大面积散热鳍片与优化的热传导通道。当设备运行产生热量时,热量通过金属机身迅速传导至散热鳍片,借助鳍片与周围空气的自然对流实现高效散热。这种无风扇设计不仅有效避免了因风扇磨损、积尘或故障导致的设备停机风险,还显著降低了运行噪音,为工业现场营造了宁静、稳定的工作环境,尤其适用于对噪音控制要求极高的精密制造、实验室检测等领域。

嵌入式安装:节省空间,美观集成

支持嵌入式安装方式,可完美嵌入工业控制柜、控制台等设备的面板中。这种安装方式不仅节省了宝贵的工业空间,使整体设备布局更加紧凑、美观,还能有效保护工控一体机免受外界碰撞与干扰。在自动化生产线的控制终端、电力配电室的监控设备等场景中广泛应用,为工业设备的集成化、智能化提供了理想的解决方案。

串口通信骨干

集成丰富的串口资源,包括 RS232、RS485 等标准串口,这些串口是工业自动化领域的经典通信接口。通过它们,SK - YPC - MX 能够与各类工业设备实现稳定可靠的连接,如可编程逻辑控制器(PLC)、传感器、仪表、变频器等。在工业生产线中,可实时采集设备运行数据,如温度、压力、流量、位置等参数,并精准地向设备发送控制指令,实现对整个生产流程的自动化监控与精准调控,确保生产过程高效、有序、稳定地进行。

IP65全面屏防尘防水

采用无缝隙全屏面板设计。四角圆弧和边框倒角处理,

形成与机柜整体相结合的美感,具有IP65防水防水防尘。

品控

工控一体机遵循严格品控体系。原材料筛选严苛,全铝机身材料纯度高、抗腐强,触控屏及电子元器件均来自优质供应商并经多重测试。生产工艺管控精密,全铝机身数控加工精度高,触控屏采用真空贴合技术确保无瑕疵,电子元器件焊接借助先进设备并精准设置参数,且产品历经多环节检测,包括性能、兼容性、稳定性及环境适应性检测,以保障在复杂工业场景下高效、稳定运行,为工业应用筑牢品质根基。

应用案例

汽车零部件生产工厂

在汽车零部件自动化生产线中,SK - YPC - MX 工控一体机发挥着核心控制作用。通过 RS485 接口与多个可编程逻辑控制器(PLC)相连,实时接收来自 PLC 的生产设备状态信息,如冲压机的压力、注塑机的温度和压力、焊接机器人的焊接参数等。

全贴合屏幕的高清显示功能让操作人员能够清晰地看到每个生产环节的实时数据和状态。例如,当冲压机的压力出现异常波动时,操作人员可以通过触摸屏幕上直观的监控界面,迅速定位问题所在,并通过一体机向 PLC 发送调整指令,精准控制冲压机的压力恢复正常。

其无风扇设计避免了在生产车间产生额外的噪音,同时也减少了因风扇故障导致的停机风险。而且,该一体机能够在车间的高温环境(可达 40℃以上)和一定程度的油污、灰尘环境下稳定运行,确保生产线的持续运转。

公司介绍

森克成立于 2012 年,是一家拥有自主品牌的国家级高新技术企业,在北京、上海、广州、佛山、深圳、杭州设有子公司,员工人数近 400 人。

经过十多年的发展与积累,森克已经形成了集研发设计、生产制造、系统集成、电子商务、销售服务等多元化经营模式,主营产品有工业三防终端、工控机、工业平板电脑、触摸教学一体机、液晶广告机、液晶拼接屏、LED 全彩屏等显示类产品。其产品应用广泛,覆盖工业互联网、物联网、人工智能、高端装备、商业显示、大数据等国家战略性新兴产业和重点领域,工业产品与商显产品在互联网市场的市场份额已连续多年位居同行业前列。

森克秉承 “ 创新为生命力 ” 的研发理念,建立占总员工人数 20% 的自主研发技术团队,具备成熟且前瞻性的研发体系,拥有 100 多项核心软硬件专利技术。2022 年,上海公司通过了专精特新小巨人的企业认证。森克以强劲的软硬件创新迭代能力,构建了坚实的技术壁垒,为森克赢得了国内外市场的高度认可与信赖,同时也让森克成长为国内商显领域内拥有自主核心技术的高新技术企业之一。

服务

质保服务

本公司为售出产品提供质保期为: 液晶显示屏保一年,线材电子料保三年 。

自您收到货签收之日起开始计算,保修期一年。保修期内,属产品本身质量问题或其他非人为因素造成的故障,可获得产品免费保修服务(三个月内返修,我司承担往返运费;超出三个月的,各自承担发出运费)。保修期外,我司收费维修,如需返厂维修由客户承担物流费用。

保修期内,我司免费维修因产品质量问题造成损坏的部件;保修期外更换部件或保修期内因客户使用不当人为造成的部件损坏,我司收取材料成本费和人工维修费。

属下述任何一种情况下,本公司均不提供免费保修服务,但可实行收费维修服务:

- 产品超出本公司所规定的保修期限的;

- 未按商品使用说明书要求使用,维护、保管而造成的故障及损坏;

- 使用指定以外的电源,电压所造成的损坏;

- 不能出示保修卡及有效购机凭证;

- 产品无本公司任何标识,或本公司的产品标签和 Logo 被撕毁、更换;

- 使用不当导致设备进水或其它溶液造成的损坏;

- 因自然灾害等不可抗力(如地震、火灾等)原因造成的故障及损坏;

- 买入后的搬运、挤压、磕碰、划伤、撞击、高温造成的故障及损坏。

- 长期使用导致产品外观磨损的不在保修范围内。