Product Description

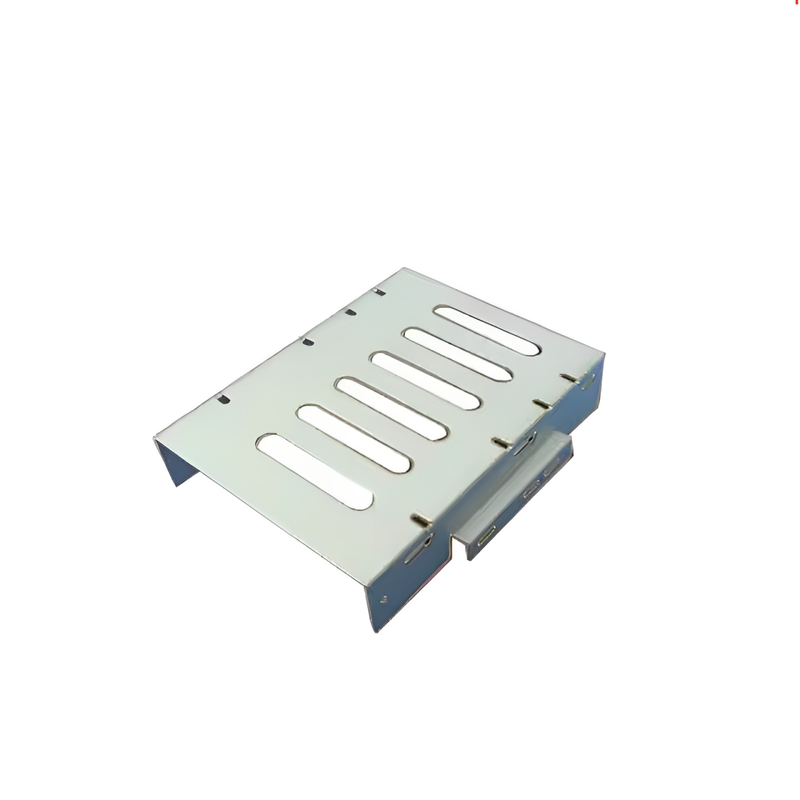

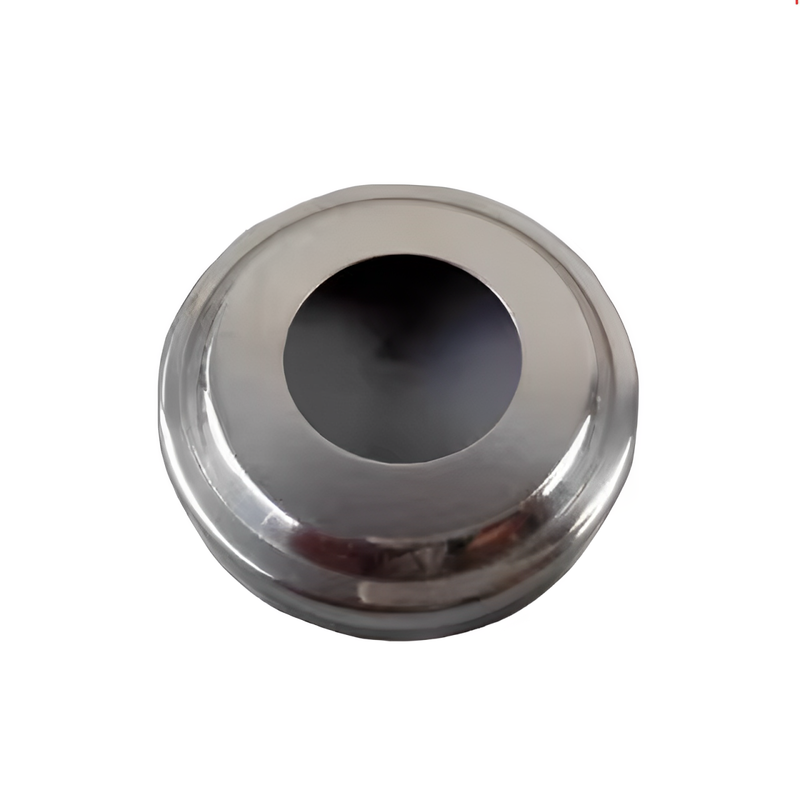

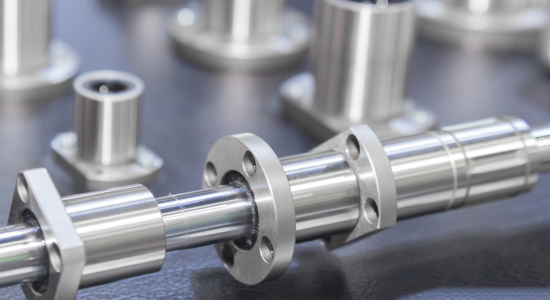

Premium stainless steel stamping parts with excellent corrosion resistance and durability, making them ideal for demanding environments. These parts are designed with precision to meet strict tolerances, ensuring consistent performance in industrial, medical, and automotive applications. Manufactured using high-quality stainless steel,

Product parameters

| Material | Steel, stainless steel, aluminum, copper, brass, alloy, etc. |

| Thickness | 0.1mm to 12mm, as your request |

| Size | As your request |

| Tolerance | 0.01mm |

| Logo service | Provided |

| Surface treatment | Zinc, nickle, chrome plating, powder coating, painting, etc. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

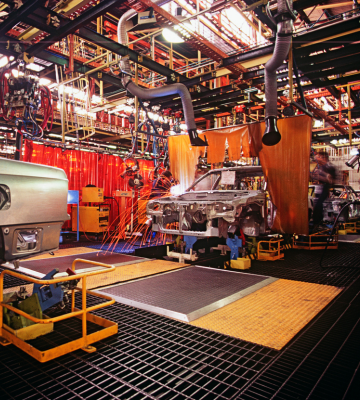

Automobiles

- Reason: Stamped metal parts such as car doors and seat frames require high strength and durability to withstand impacts and vibrations in harsh environments.

- Advantage: The stamping process produces precise and durable parts, which is crucial in the automotive industry

Car Doors

• Reason: Car doors require strength and durability to protect passengers in the event of an accident. The stamping die process ensures parts with precision and a shape that fits perfectly with the car body.

Communication Devices and Antennas

- Reason: Antenna frames and parts in communication devices require precision and durability for use in outdoor conditions. Metal bending and stamping produce sturdy, easy-to-assemble components.

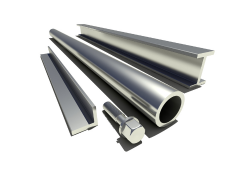

Material

Iron

Stainless Steel

Aluminum Alloy

Quality Control

Quality control for stainless steel stamping parts involves thorough inspections at every stage of the manufacturing process to ensure precision, durability, and compliance with industry standards. This includes dimensional checks, surface quality assessments, and material testing to confirm the parts meet required specifications. Advanced inspection tools such as coordinate measuring machines (CMM) and visual inspections are used to detect any defects or inconsistencies.

Processing capability

The processing capability of stainless steel stamping parts includes precise cutting, bending, and forming to produce complex shapes and designs with tight tolerances. Advanced stamping equipment is used to handle various grades and thicknesses of stainless steel, ensuring consistent quality and accuracy across large production runs. The process also supports additional operations such as punching, embossing, and piercing, allowing for versatility in creating parts for a wide range of industrial, medical, and automotive applications.

Additional processes

Additional processes for stainless steel stamping parts include surface treatments such as polishing, coating, and anodizing to enhance corrosion resistance, appearance, and durability. Secondary operations like welding, threading, assembly, and laser cutting are performed to meet specific functional and design requirements.