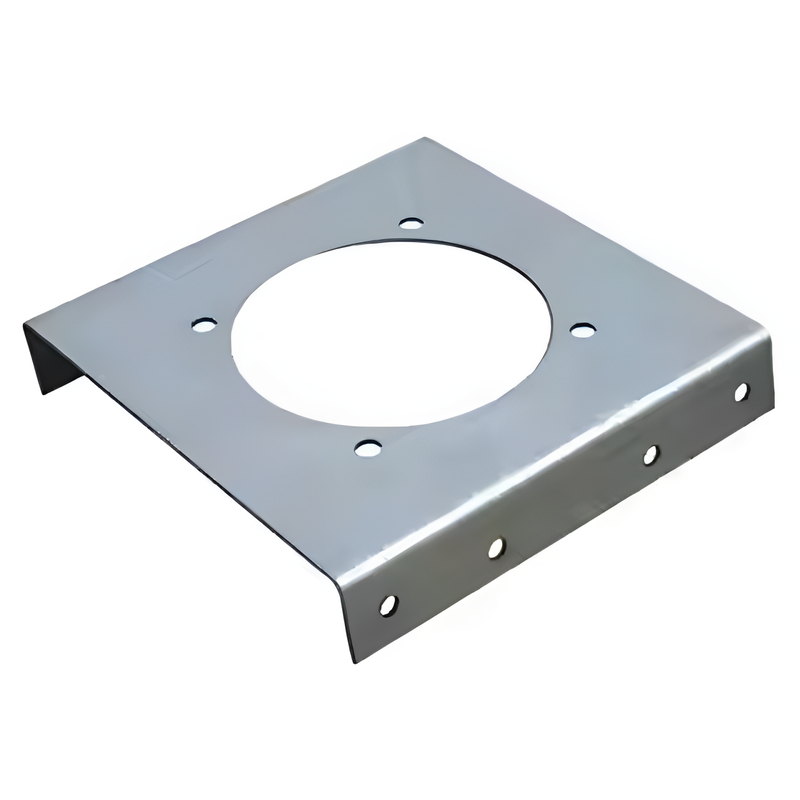

Product Description

AlumiShield CNC Enclosures: Rugged, precision-engineered aluminum housings, offering superior protection and durability for electronic and industrial applications. Designed to withstand harsh environments, these enclosures provide excellent resistance to corrosion, impact, and extreme temperatures. Manufactured with advanced CNC machining techniques, each enclosure is tailored to fit specific components, ensuring a precise fit and easy installation.

Product parameters

| Machining Services | CNC turning, CNC milling, reaming, drilling, tapping, laser cutting, bending, rotation, wire cutting, stamping, electrical discharge machining (EDM) |

| Molding services | Injection molding, overmolding, insert molding |

| Materials used | Metal: Aluminum, stainless steel, steel, brass, copper, plastic, titanium |

| Plastic: ABS, PP, PEEK, PA6, TEFLON, PVDF | |

| Surface treatment | Anodizing, bead spraying, wire mesh, PVD electroplating, zinc/nickel/chromium/titanium electroplating, brushing, painting, powder coating |

| Product assembly | Mechanical assembly, Electronic products assembly, programming, testing, traceability |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Outdoor Electronics

Reason: AlumiShield CNC Enclosures are used to protect outdoor electronic devices such as smart lighting systems or temperature measurement sensors, as the aluminum material is resistant to weather conditions and corrosion.

Telecommunication Equipment

Reason: In communication equipment, such as network switches or servers, AlumiShield CNC Enclosures provide effective protection from heat and impact, which is essential for stable performance.

Industrial Control Panels

Reason: Used in industrial control panels to protect electrical circuits and components from environmental damage, such as moisture or dust. AlumiShield CNC Enclosures ensure safety and long-lasting performance.

Material

Aluminum Alloy

Stainless Stee

Copper

Quality Control

Quality control of AlumiShield CNC Enclosures involves a rigorous process to ensure each enclosure meets the highest standards of durability, precision, and functionality. It begins with the inspection of raw materials, ensuring the aluminum used is of premium quality and suitable for the intended application. During manufacturing, advanced CNC machining techniques are employed to achieve precise dimensions and smooth finishes.

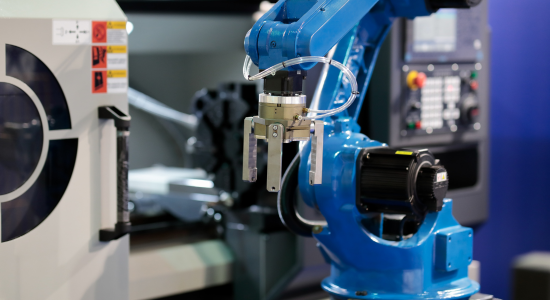

Processing capability

The processing capability of AlumiShield CNC Enclosures includes a wide range of advanced manufacturing techniques designed to produce high-precision, durable aluminum housings. Using state-of-the-art CNC machining, each enclosure is precisely crafted to meet specific design requirements, ensuring tight tolerances and smooth finishes. The process involves cutting, milling, drilling, and tapping to create custom shapes and features for different applications. Additionally, the enclosures can undergo secondary processes such as anodizing or powder coating to enhance corrosion resistance and surface durability.

Additional processes

Additional processes for AlumiShield CNC Enclosures include secondary operations designed to enhance the functionality and performance of the enclosures. After the initial CNC machining, these enclosures can undergo processes such as anodizing to improve corrosion resistance and provide a durable, aesthetically pleasing finish. Powder coating may also be applied to further protect the surface from wear and environmental elements.