Huraian Produk

Sebagai tambahan kepada pemesinan CNC, Mangkuk Kon (Tiada Slot) Mesin CNC Tersuai boleh menjalani beberapa proses tambahan untuk meningkatkan prestasi dan fungsinya. Ini termasuk rawatan permukaan seperti anodisasi atau salutan untuk meningkatkan rintangan kakisan dan memanjangkan jangka hayat bahagian tersebut. Rawatan haba boleh digunakan untuk meningkatkan kekerasan dan rintangan haus, menjadikan mangkuk lebih tahan lama dalam persekitaran yang keras.

Parameter produk

| Saiz Produk | Diameter: 360 mm,Ketinggian: 360 mm, Ketebalan: 42 mm |

| Ciri-ciri | Hayat Perkhidmatan Lama, Ketepatan, Tahan Lama, Mesra Alam, Lestari |

| Perkhidmatan | OEM,Tersuai |

| Kelebihan | Teknologi Profesional, Kualiti Tinggi |

Proses Suai

1.menghantar pertanyaan

2.lukisan atau sampel

3. Sebutharga

4.pengesahan pelanggan

5. membuat pesanan dan membayar

6. Pengeluaran besar-besaran

7. Uji sebelum pembungkusan

8.Penghantaran & pengesahan

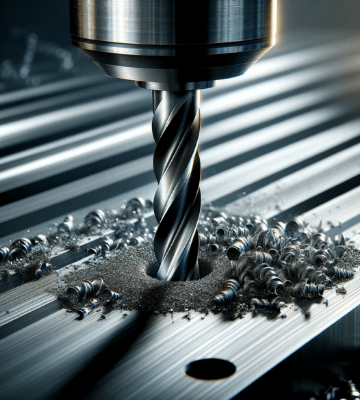

Jenis Proses

Mesin Pengilangan CNC

Pengeboran

Pengilapan

Material

Aloi Aluminium

Keluli Tahan Karat

Kawalan Kualiti

Kawalan kualiti kami untuk Bahagian Gland & Logam Ketepatan yang Diperbuat dengan CNC memastikan bahawa setiap komponen memenuhi piawaian tertinggi dari segi ketahanan dan ketepatan. Setiap bahagian menjalani proses pemeriksaan yang teliti semasa dan selepas pemesinan untuk menjamin dimensi yang tepat, permukaan yang licin, dan prestasi yang boleh dipercayai. Kami menggunakan alat pengukuran dan teknik canggih untuk mengesahkan toleransi yang ketat dan mengesan sebarang kecacatan yang berpotensi.

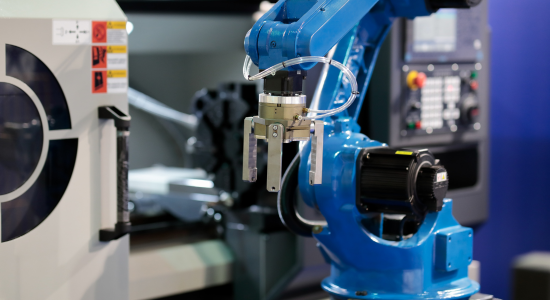

Kemampuan proses

Keupayaan pemprosesan untuk Bahagian Gland & Logam Ketepatan yang Diperbuat dengan CNC kami merangkumi teknik pemesinan CNC canggih yang membolehkan kami menghasilkan bahagian yang sangat tepat dan kompleks daripada pelbagai jenis bahan. Keupayaan kami meliputi toleransi yang ketat, permukaan licin, dan reka bentuk yang rumit, memastikan setiap komponen memenuhi spesifikasi yang diperlukan untuk ketahanan dan fungsi. Kami menggunakan peralatan dan teknologi terkini untuk mengendalikan kedua-dua pengeluaran kecil dan besar dengan cekap, memberikan fleksibiliti dan output berkualiti tinggi untuk pelbagai aplikasi industri.

Proses tambahan

Selain pemesinan CNC, Bahagian Gland & Logam Ketepatan yang Diperbuat dengan CNC kami menjalani pelbagai proses tambahan untuk memastikan prestasi dan kualiti yang dipertingkatkan. Ini termasuk rawatan permukaan seperti anodisasi, salutan, atau pengilapan untuk meningkatkan ketahanan terhadap kakisan dan penampilan. Kami juga menawarkan rawatan haba untuk meningkatkan kekerasan dan ketahanan bahagian logam. Di samping itu, operasi kedua seperti mengetuk, pemintalan, dan pemasangan boleh dilakukan untuk memenuhi keperluan pelanggan yang khusus.