Huraian Produk

Komponen CNC logam tersuai berketepatan tinggi, direka khas untuk keperluan industri, dihasilkan menggunakan teknologi dan teknik CNC terkini untuk memastikan ketepatan dan ketahanan yang terbaik. Perkhidmatan kami memenuhi pelbagai industri, termasuk automotif, aeroangkasa, robotik dan perubatan, menyediakan penyelesaian yang disesuaikan yang memenuhi keperluan prestasi dan reka bentuk khusus. Daripada geometri kompleks kepada toleransi halus, kami pakar dalam menghasilkan bahagian yang memerlukan ketukangan yang teliti dan piawaian yang tepat.

Parameter produk

| Type | Stainless Steel or Iron CNC Turning Parts |

| Material | Steel Alloy: 1020, AISI5135 |

| Surface Treatment | Oxide, Electric Polishing, Plating, Powder Coating, Painting |

| Feature | Custom service |

| Sample | Samples Offered |

Proses Suai

1.menghantar pertanyaan

2.lukisan atau sampel

3. Sebutharga

4.pengesahan pelanggan

5. membuat pesanan dan membayar

6. Pengeluaran besar-besaran

7. Uji sebelum pembungkusan

8.Penghantaran & pengesahan

Jenis Proses

Die casting

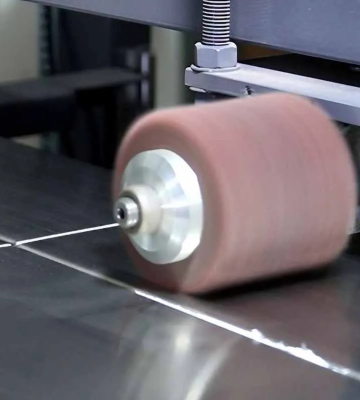

Menggilap

Pemesinan CNC

Material

Aloi Aluminium

Keluli Tahan Karat

Kawalan Kualiti

Kawalan kualiti untuk komponen tersuai CNC profesional adalah bahagian penting dalam proses pembuatan, memastikan setiap bahagian memenuhi piawaian ketepatan dan prestasi tertinggi. Setiap komponen menjalani beberapa siri pemeriksaan ketat sepanjang pengeluaran, termasuk pengesahan dimensi menggunakan alat ukuran lanjutan seperti mesin pengukur koordinat (CMM) dan pengimbas laser.

Kemampuan proses

Keupayaan pemprosesan komponen tersuai CNC profesional merangkumi rangkaian luas teknik pemesinan termaju yang memastikan ketepatan tinggi, fleksibiliti dan serba boleh dalam pengeluaran. Menggunakan mesin CNC yang canggih, kami dapat melakukan pengilangan berbilang paksi, memusing, menggerudi dan mengisar dengan ketepatan yang luar biasa, menghasilkan bahagian dengan toleransi yang ketat dan geometri yang kompleks. Kepelbagaian mesin ini membolehkan kami bekerja dengan pelbagai jenis bahan, termasuk logam, plastik dan komposit, menyediakan penyelesaian yang disesuaikan dengan keperluan khusus setiap pelanggan.

Proses tambahan

Proses tambahan untuk komponen tersuai CNC profesional dilaksanakan untuk meningkatkan kefungsian, estetika dan prestasi bahagian tersebut. Proses ini termasuk rawatan permukaan seperti anodisasi, salutan dan penggilap, yang meningkatkan rintangan kakisan, kekerasan permukaan dan kemasan keseluruhan. Untuk komponen yang memerlukan peningkatan ketahanan, proses seperti rawatan haba atau pemprosesan haba digunakan untuk meningkatkan sifat mekanikal seperti kekuatan tegangan dan kekerasan. Bergantung pada aplikasi, bahagian mungkin mengalami deburring dan pembersihan untuk membuang tepi tajam dan bahan cemar, memastikan operasi lancar dan keselamatan.