Product Description

Stainless Steel Flat Head Rivet Screws, corrosion-resistant and durable, perfect for leatherwork like belts, wallets, handbags, and other accessories. These screws are designed for easy installation, providing a secure and strong connection for a variety of leather products. The flat head ensures a smooth, flush finish, giving a clean and professional appearance to your creations. Made from high-quality stainless steel, they offer excellent resistance to wear and tear, making them ideal for both everyday use and high-demand applications.

Product parameters

| Material | Stainless Steel Brass |

| Finish | Polished |

| Type | Chicago Screw |

| Product Name | Stainless Steel Flat Head Chicago Screws |

| Technology | CNC |

| OEM | Accept |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

Die Casting

Deburring

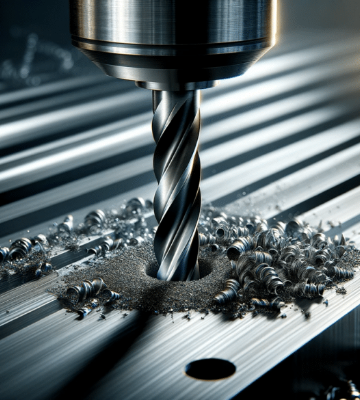

Drilling

Material

Aluminum Alloy

Zinc Alloy

Alloy Steel

Stainless Steel

Quality Control

Quality control of Stainless Steel Flat Head Rivet Screws ensures that each component meets strict standards of durability, precision, and functionality. Every screw undergoes a series of inspections throughout the manufacturing process, including dimensional accuracy checks, surface quality assessments, and material integrity tests. The stainless steel material is examined for resistance to corrosion and strength to ensure long-lasting performance in various environments.

Processing capability

The processing capability of Stainless Steel Flat Head Rivet Screws includes a wide range of advanced manufacturing techniques to achieve high precision and quality. Using CNC technology, the screws are produced with tight tolerances and a smooth finish. The stainless steel material is carefully selected and machined to ensure durability and resistance to corrosion. Additional processes such as polishing are applied to achieve a smooth, professional surface.

Additional processes

Additional processes for Stainless Steel Flat Head Rivet Screws include surface treatments such as polishing, electroplating, and anodizing to enhance their corrosion resistance, durability, and aesthetic appearance. These processes ensure a smooth, polished finish and improve the screws' resistance to wear and environmental factors, making them suitable for use in demanding applications. Furthermore, any necessary laser marking or engraving is applied for identification purposes or branding.