Mô tả sản phẩm

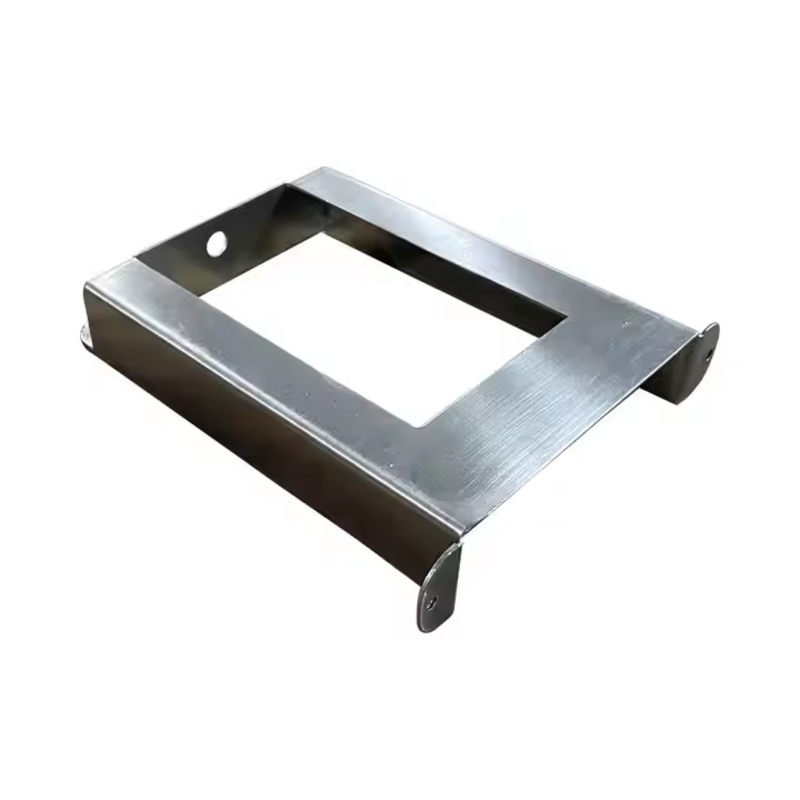

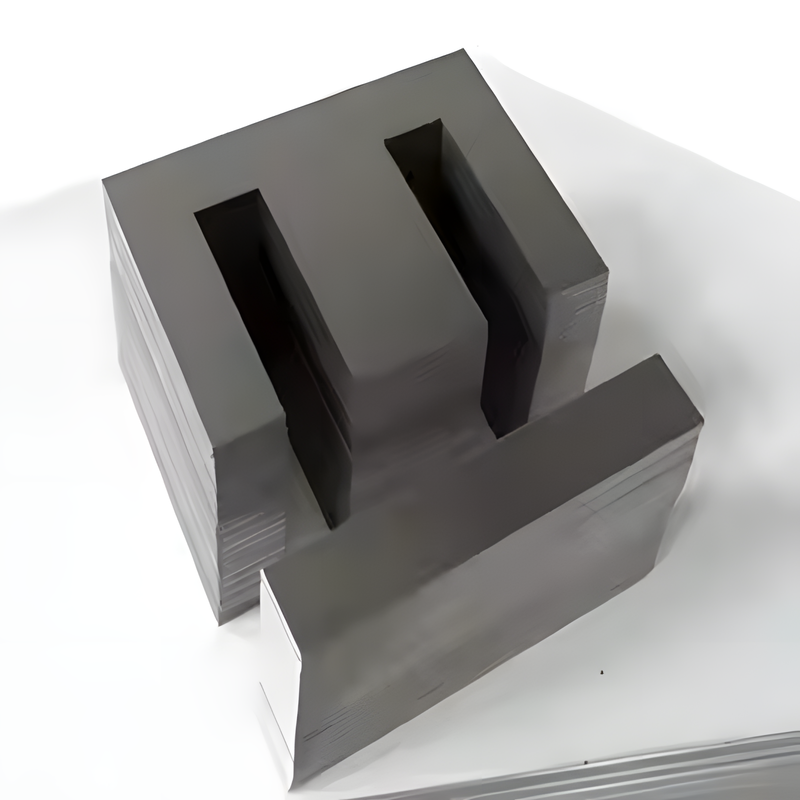

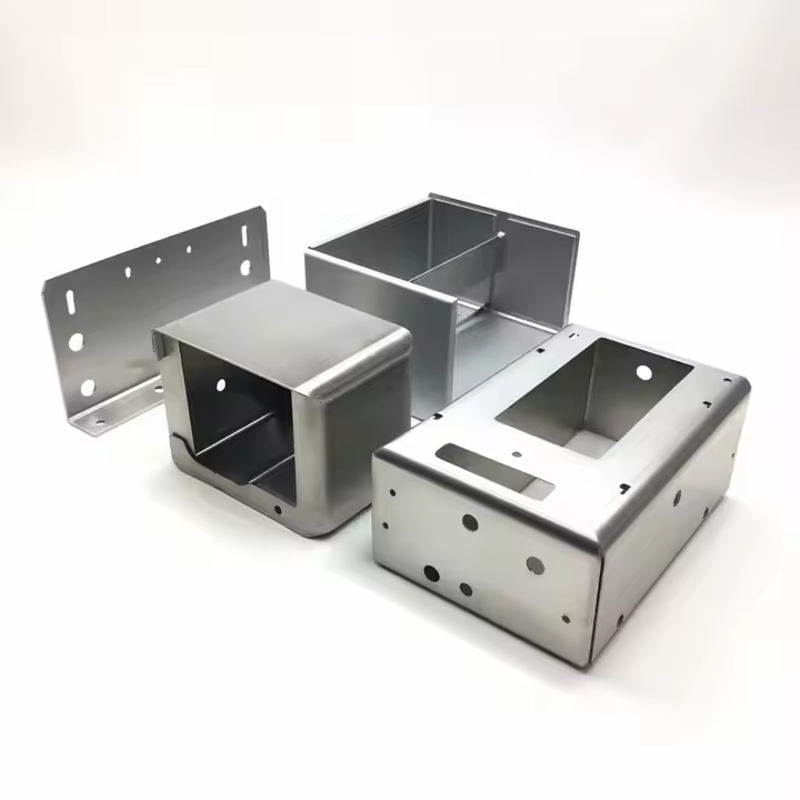

Thiết bị điện tử làm từ thép không gỉ mang lại độ bền và khả năng chống ăn mòn, đảm bảo hiệu suất lâu dài. Độ mạnh của thép không gỉ cung cấp tính toàn vẹn cấu trúc cho các linh kiện điện tử nhạy cảm. Nó cũng cung cấp khả năng tản nhiệt tuyệt vời, làm cho nó lý tưởng cho các thiết bị hiệu suất cao. Các tính chất không phản ứng của vật liệu bảo vệ thiết bị điện tử khỏi các tác động từ môi trường. Vỏ thép không gỉ thường được sử dụng trong các vỏ bọc, đầu nối và bộ tản nhiệt. Sự kết hợp giữa độ bền và tính năng này khiến thép không gỉ trở thành lựa chọn phổ biến cho các thiết bị điện tử trong nhiều ngành công nghiệp.

Thông số sản phẩm

| Danh mục | Chi tiết |

|---|---|

| Tên thương hiệu | Thiết bị điện tử thép không gỉ |

| Tên | Vỏ của thiết bị điện tử |

| Quy trình | Uốn, Dập kim loại |

| Độ chính xác | ISO9001:2008 |

| Chứng nhận | 0.1-0.3mm |

| Dịch vụ bảo hành | Dịch vụ sau bán hàng 7*24 giờ |

| Loại | Các bộ phận kim loại tấm |

| Dịch vụ | OEM\ODM |

Quy trình tùy chỉnh

1. ửi yêu cầu báo giá

2.Bản vẽ hoặc mẫu

3.Báo giá

4.Xác nhận của khách hàng

5.Đặt hàng và thanh toán

6.Sản xuất hàng loạt

7.Kiểm tra trước khi đóng gói

8.Vận chuyển & xác nhận

Loại quy trình

Tiện

Phay & Khoan

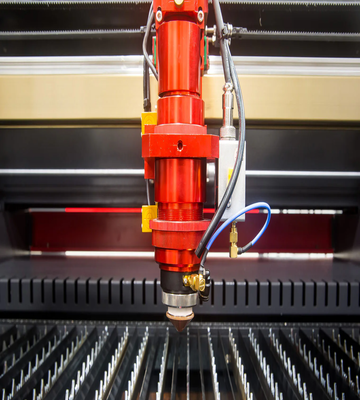

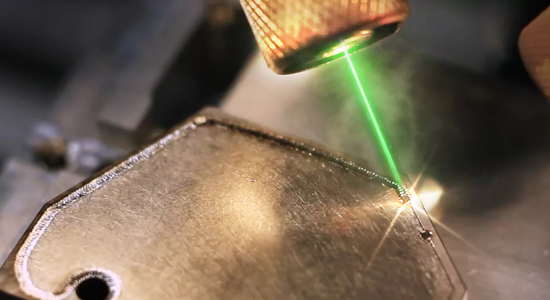

Cắt Laser

Chất liệu

Tấm nhôm

Tấm đồng thau

Tấm đồng

Kiểm soát chất lượng

Kiểm tra chất lượng của thiết bị điện tử làm từ thép không gỉ bao gồm việc kiểm tra nghiêm ngặt chất lượng vật liệu và bề mặt hoàn thiện. Các linh kiện thép không gỉ được kiểm tra khả năng chống ăn mòn và độ bền dưới các điều kiện môi trường khác nhau. Độ chính xác kích thước được kiểm tra để đảm bảo sự vừa vặn và chức năng đúng trong các thiết bị điện tử. Các hoàn thiện bề mặt, như độ mịn và sự vắng mặt của khuyết tật, được đánh giá cẩn thận. Kiểm tra chức năng đảm bảo rằng thiết bị điện tử hoạt động đúng trong vỏ thép không gỉ. Kiểm tra cuối cùng xác nhận sự tuân thủ các tiêu chuẩn ngành và yêu cầu của khách hàng.

Khả năng xử lý

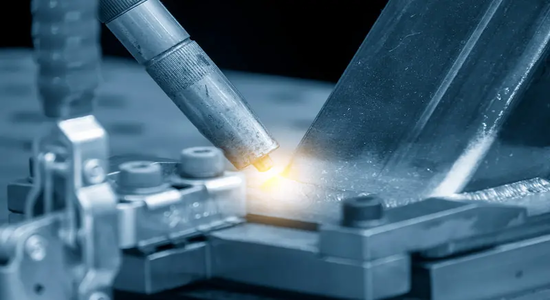

Khả năng gia công của thiết bị điện tử làm từ thép không gỉ bao gồm cắt chính xác, uốn và hàn để tạo ra các hình dạng và kích thước tùy chỉnh. Máy móc CNC tiên tiến đảm bảo kích thước chính xác và độ chính xác cao cho các linh kiện điện tử. Thép không gỉ có thể được cắt bằng laser để tạo ra các thiết kế tinh xảo, đảm bảo lãng phí vật liệu tối thiểu. Nó có thể được uốn thành các góc và bán kính khác nhau, mang lại sự linh hoạt trong thiết kế các vỏ bọc và chi tiết. Vật liệu này phù hợp cho việc hàn, tạo ra các mối nối chắc chắn và duy trì tính toàn vẹn cấu trúc. Thép không gỉ cũng có thể được đánh bóng hoặc chải để đạt được bề mặt hoàn thiện mong muốn.

Quy trình khác

Các kỹ thuật gia công tiên tiến cho phép sản xuất các chi tiết tinh xảo, cần thiết cho việc bao bọc các linh kiện điện tử nhạy cảm. Khả năng chống ăn mòn và nhiệt độ cao của vật liệu làm cho nó lý tưởng cho các linh kiện bền vững và đáng tin cậy. Nó có thể được xử lý bằng các lớp phủ hoặc quá trình passivation để nâng cao hiệu suất. Thép không gỉ cũng nhẹ, điều này mang lại lợi thế cho các thiết bị điện tử di động. Tính linh hoạt của vật liệu cho phép sản xuất từ các linh kiện nhỏ đến các vỏ bọc lớn. Tổng thể, gia công thép không gỉ cho thiết bị điện tử đảm bảo độ bền, tính năng và sự hấp dẫn về thẩm mỹ.