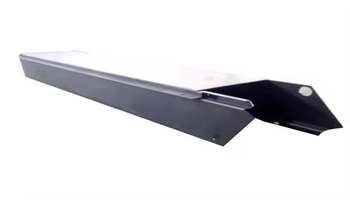

Mô tả sản phẩm

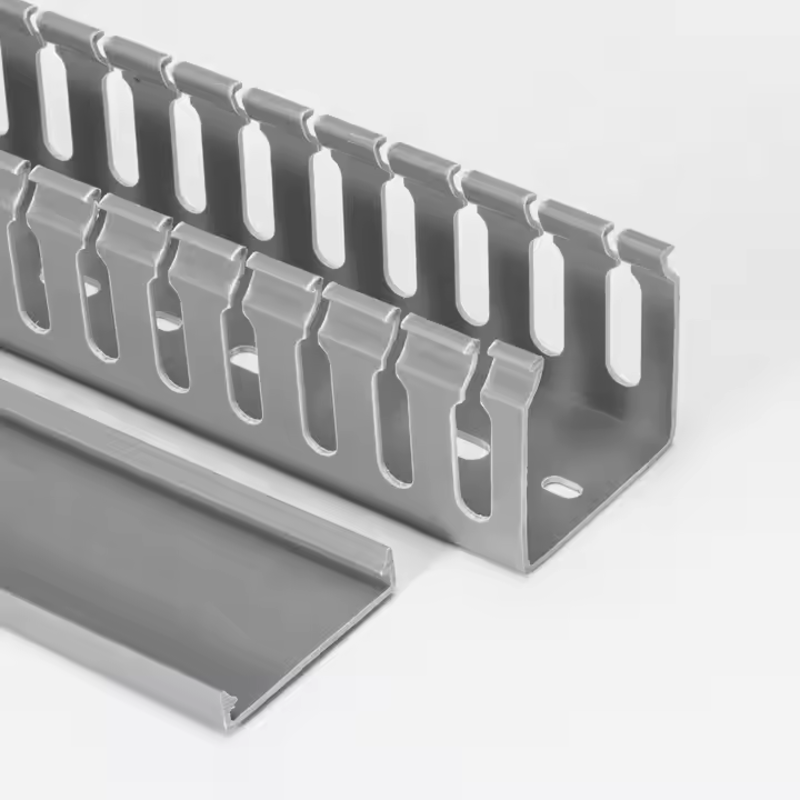

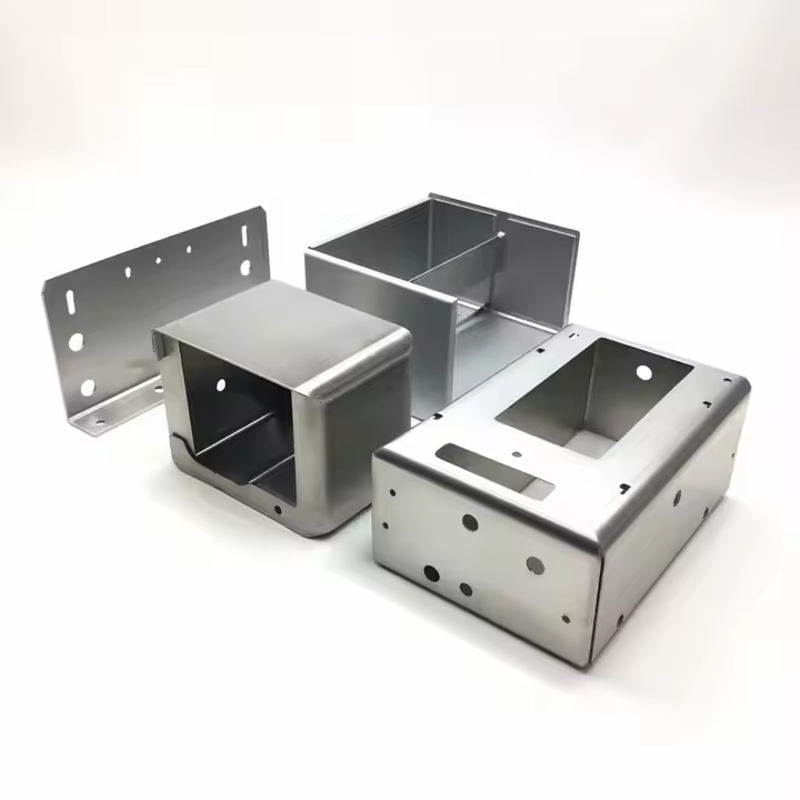

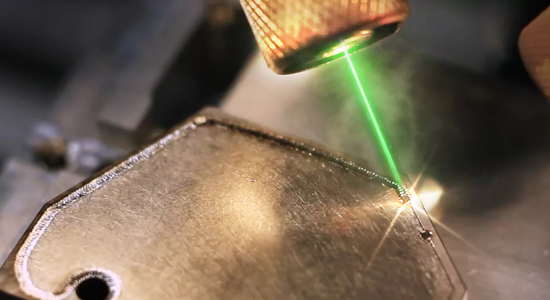

Phay CNC kim loại chính xác cao là một quá trình gia công tạo ra các chi tiết phức tạp với độ chính xác chặt chẽ từ nhiều loại kim loại khác nhau. Nó sử dụng thiết bị điều khiển bằng máy tính để loại bỏ vật liệu, đảm bảo độ chính xác và tính lặp lại. Phương pháp này lý tưởng cho các hình học phức tạp, sản xuất bề mặt mịn và chi tiết sắc nét. Nó hỗ trợ nhiều loại kim loại, bao gồm nhôm, thép và titan. Phay CNC mang lại kết quả chất lượng cao cho các ngành công nghiệp như hàng không, ô tô và y tế. Quá trình này đảm bảo lãng phí vật liệu tối thiểu và thời gian sản xuất nhanh chóng.

Thông số sản phẩm

| Danh mục | Chi tiết |

|---|---|

| Tên thương hiệu | Phay CNC Kim Loại Chính Xác Cao |

| Vật liệu | Thép không gỉ / Thép carbon / Nhôm |

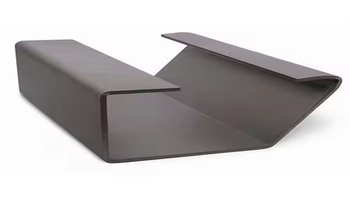

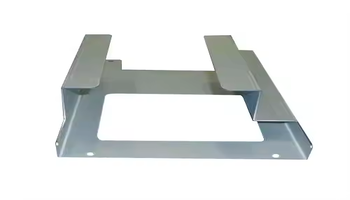

| Quy trình | Đột lỗ CNC, Uốn, Hàn |

| Độ chính xác | 0.1-0.3mm |

| Chứng nhận | ISO-9001 |

| Số lượng tối thiểu | 5 chiếc |

| Loại | Phủ bột |

| Xử lý bề mặt | Các bộ phận kim loại tấm chế tạo cho máy |

Quy trình tùy chỉnh

1. ửi yêu cầu báo giá

2.Bản vẽ hoặc mẫu

3.Báo giá

4.Xác nhận của khách hàng

5.Đặt hàng và thanh toán

6.Sản xuất hàng loạt

7.Kiểm tra trước khi đóng gói

8.Vận chuyển & xác nhận

Loại quy trình

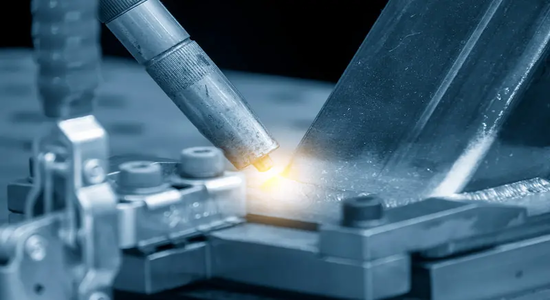

Tiện

Phay & Khoan

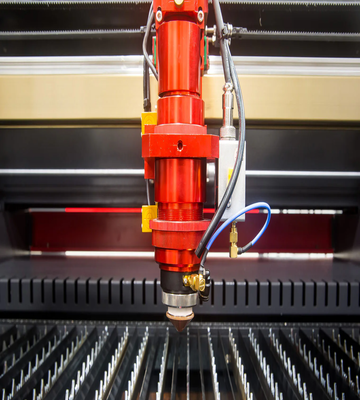

Cắt Laser

Chất liệu

Tấm nhôm

Tấm đồng thau

Tấm đồng

Kiểm soát chất lượng

Kiểm tra chất lượng phay CNC kim loại chính xác cao bao gồm việc kiểm tra nghiêm ngặt kích thước của các chi tiết bằng các công cụ đo lường tiên tiến. Độ chính xác được xác minh để đảm bảo chúng đáp ứng các yêu cầu thiết kế. Các hoàn thiện bề mặt được kiểm tra độ mịn và sự nhất quán. Tính toàn vẹn của vật liệu được kiểm tra để phát hiện các khuyết tật hoặc sai sót. Mỗi chi tiết đều trải qua thử nghiệm chức năng để đảm bảo chúng hoạt động như mong muốn. Kiểm tra cuối cùng xác nhận rằng chi tiết đáp ứng tất cả các tiêu chuẩn ngành và yêu cầu của khách hàng.

Khả năng xử lý

Phay CNC kim loại chính xác cao mang lại độ chính xác tuyệt vời cho việc sản xuất các hình học phức tạp và các chi tiết tinh xảo. Quá trình này có thể xử lý nhiều loại kim loại, bao gồm nhôm, thép không gỉ, titan và hợp kim, đảm bảo tính linh hoạt. Quá trình cho phép độ chính xác chặt chẽ, thường chỉ trong vài micron, làm cho nó lý tưởng cho các ứng dụng yêu cầu cao. Máy phay CNC có thể làm việc với cả thiết kế 2D và 3D, cho phép sản xuất các chi tiết tỉ mỉ. Khả năng phay đa trục cho phép tạo ra các chi tiết có hình dạng và góc phức tạp. Các hoàn thiện bề mặt luôn mịn màng, giảm thiểu nhu cầu gia công thêm. Quá trình này có thể tạo ra các lỗ, khe, ren và các đường viền với độ chính xác cao.

Quy trình khác

Phay CNC có khả năng cắt tốc độ cao, cải thiện hiệu quả trong cả sản xuất nhỏ và sản xuất quy mô lớn. Nó cũng cung cấp khả năng mở rộng, làm cho nó phù hợp cho cả việc tạo mẫu và sản xuất quy mô lớn. Khả năng sử dụng công cụ tiên tiến mang lại sự linh hoạt tuyệt vời cho sự thay đổi về vật liệu và thiết kế. Phay CNC giảm thiểu lãng phí vật liệu, tối ưu hóa cả chi phí và thời gian sản xuất. Tổng thể, nó mang lại các chi tiết đáng tin cậy, chất lượng cao cho các ngành công nghiệp như hàng không, ô tô và công nghệ y tế.