คำอธิบายผลิตภัณฑ์

บริการงานกลึง CNC แบบกำหนดเองที่ให้บริการการกลึง การกัด และการเจาะที่มีความแม่นยำ เพื่อสร้างชิ้นส่วนคุณภาพสูงที่ออกแบบมาเฉพาะจากวัสดุหลากหลายประเภท รวมถึงโลหะ พลาสติก และวัสดุผสม เรามีความเชี่ยวชาญในการผลิตชิ้นส่วนที่มีค่าความคลาดเคลื่อนต่ำและมีรูปทรงที่ซับซ้อนสำหรับอุตสาหกรรมต่างๆ เช่น อวกาศ ยานยนต์ การแพทย์ และอิเล็กทรอนิกส์

พารามิเตอร์ผลิตภัณฑ์

| ชื่อผลิตภัณฑ์ | งานกลึง CNC แบบกำหนดเอง |

| คำสำคัญ | การกลึง CNC ที่มีความแม่นยำสูง |

| วัสดุ | อลูมิเนียม/ทองเหลือง/พลาสติก/ทองแดง/โลหะผสมไทเทเนียม/เหล็ก/โลหะผสมเหล็ก |

| อุปกรณ์ | ศูนย์เครื่องจักรกลสามแกน, สี่แกน, ห้าแกน |

| กระบวนการ | การกลึง CNC; การมิลลิ่ง CNC |

| การใช้งาน | อุปกรณ์อุตสาหกรรม |

| รูปแบบแผ่นงาน | 2D/(PDF/DWG) 3D(IGES/STEP) |

| การบำบัดพื้นผิว | การอโนไดซ์, การชุบโลหะ |

| การบริการ | การปรับแต่งตามคำสั่ง OEM |

กระบวนการที่กำหนดเอง

1. การสอบถามลูกค้า

2.ส่งแบบ/ตัวอย่าง

3. การทำแม่พิมพ์

4. การประมวลผลของเครื่องจักร

5. การควบคุมคุณภาพ

6. การบรรจุหีบห่อ

7. การขนส่ง

8. การสนับสนุนหลังการขาย

ประเภทกระบวนการ

การลบคม

การหล่อแบบไดคาสติ้ง

การขัดเงา

วัสดุ

โลหะผสมอลูมิเนียม

โลหะผสมสังกะสี

เหล็กอัลลอยด์

สแตนเลส

การควบคุมคุณภาพ

การควบคุมคุณภาพสำหรับเครื่องจักร CNC แบบกำหนดเองถูกบูรณาการตลอดกระบวนการผลิตทั้งหมดเพื่อให้มั่นใจถึงมาตรฐานสูงสุดของความแม่นยำและความน่าเชื่อถือ โดยใช้เครื่องมือตรวจสอบขั้นสูง เช่น เครื่องวัดพิกัด (CMM) เครื่องสแกนแบบออปติคัล และเกจวัดความแม่นยำ เราทำการตรวจสอบอย่างละเอียดเกี่ยวกับขนาดที่สำคัญ การตกแต่งพื้นผิว และความสมบูรณ์ของวัสดุ

ความสามารถในการประมวลผล

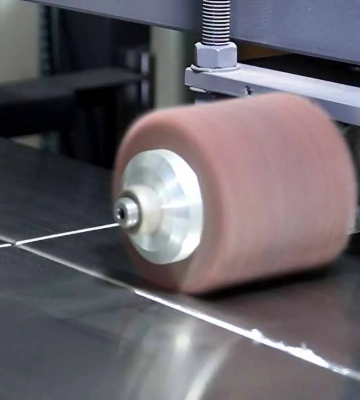

ความสามารถในการประมวลผลของเราสำหรับงานกลึง CNC แบบกำหนดเอง ได้แก่ การกลึง การกัด และการเจาะที่มีความแม่นยำสูง ทำให้เราทำงานกับวัสดุได้หลากหลายประเภท เช่น โลหะ พลาสติก และวัสดุผสม เราเชี่ยวชาญในการสร้างรูปทรงเรขาคณิตที่ซับซ้อนโดยมีค่าความคลาดเคลื่อนต่ำ เพื่อให้แน่ใจว่ามีความแม่นยำถึงระดับไมครอน เครื่องจักร CNC ขั้นสูงของเรารองรับการทำงานแบบหลายแกน ทำให้เราผลิตชิ้นส่วนที่ซับซ้อนด้วยรายละเอียดและพื้นผิวที่เรียบเนียนเป็นพิเศษ

กระบวนการอื่น ๆ

นอกเหนือจากการกลึง การกัด และการเจาะ บริการงานกลึง CNC แบบกำหนดเองของเรายังรวมถึงกระบวนการรองที่หลากหลายเพื่อเพิ่มประสิทธิภาพการใช้งานและการตกแต่งชิ้นส่วนของคุณ กระบวนการเหล่านี้ได้แก่ การทำเกลียว การต๊าป และการเจียรพื้นผิวเพื่อให้แน่ใจว่ามีความแม่นยำและพื้นผิวเรียบ นอกจากนี้ เรายังเสนอบริการหลังการกลึง เช่น การลบครีบ การขัด และการอบชุบด้วยความร้อนเพื่อปรับปรุงประสิทธิภาพและความทนทานของชิ้นส่วน