Product Description

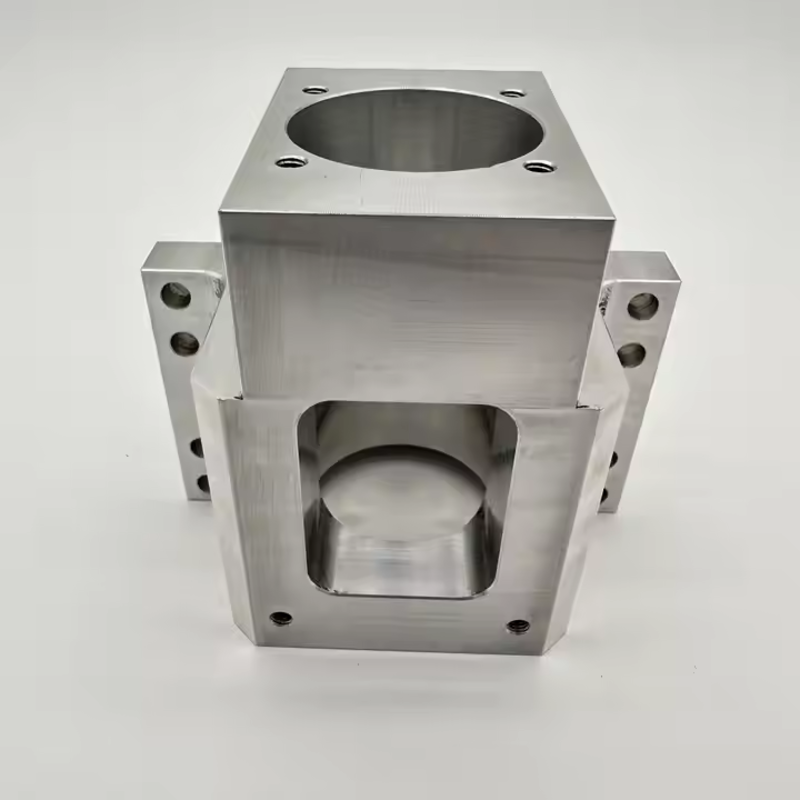

OEM Custom Precision Stainless Steel offers high-accuracy, customized stainless steel solutions for various applications. Manufactured to strict specifications, these products ensure superior performance and durability. Our advanced machining techniques guarantee tight tolerances and precise dimensions. The stainless steel is resistant to corrosion, making it ideal for harsh environments. We provide various surface finishes to meet aesthetic and functional requirements. Trusted by industries for its reliability, precision, and quality.

Product parameters

| List | Details |

|---|---|

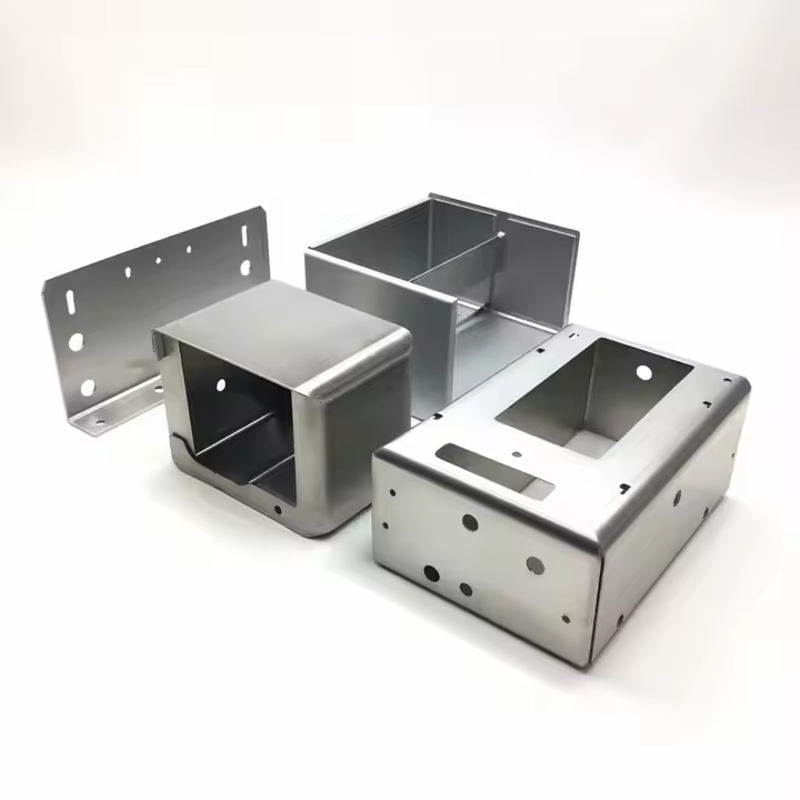

| Product name | Custom sheet metal fabrication Parts |

| Thickness | 0.1mm-12mm |

| Materials | Zinc, alunimum, copper, steel, powder coating, etc. |

| Surface treatment | Electric plating,powder coated,sand blasting,lacquer |

| Process | Punching, stamping, bending, riveting, etc. |

| Technology | Stamping |

| Service | Stainless steel part sheet metal stamping parts air conditioning parts |

| Testing | Salt spray |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Turning

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The QC process for OEM Custom Precision Stainless Steel ensures every product meets stringent quality standards. Detailed inspections are performed at each production stage, including material verification and dimensional checks. Advanced testing methods, such as tensile and hardness testing, ensure superior strength and durability. Surface finishes are thoroughly checked for consistency and precision. Any deviations from specifications are immediately addressed. Only products that pass comprehensive quality control are shipped to customers.

Processing capability

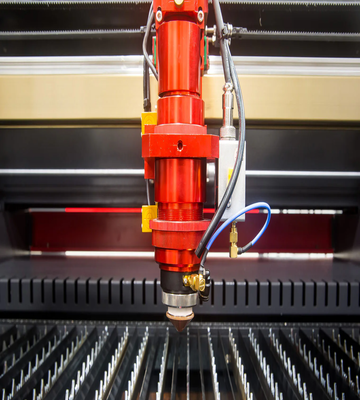

The processing capability of OEM Custom Precision Stainless Steel includes advanced CNC machining for high-precision milling, turning, and drilling. We offer tight tolerances and customized dimensions to meet specific client needs. Our facility is equipped with state-of-the-art equipment for various processes such as bending, welding, and laser cutting. Heat treatment is applied to enhance material strength and performance, ensuring long-lasting durability. We provide surface finishing options such as polishing, brushing, and coating for a refined appearance.

Additional processes

Our experienced team ensures every part meets exact specifications and quality standards. We handle both small and large batch production efficiently. With rapid prototyping capabilities, we offer quick turnaround times for custom projects. Our robust testing process includes checks for corrosion resistance and material strength. We offer flexibility in design and production to accommodate complex and intricate parts. All processes are designed to maintain high precision and quality throughout the manufacturing cycle. We ensure reliable and consistent output for diverse industries, including automotive, industrial, and electronics.