Huraian Produk

Produk tuangan ketepatan bahagian motosikal kami adalah penjelmaan teknologi terbaik dan kepintaran yang muktamad. Kami menggunakan tuangan lilin hilang termaju, tuangan pelaburan dan proses lain untuk mengawal setiap perincian pada tahap mikron bagi memastikan bahagian itu tepat dari segi saiz dan permukaan licin, dan boleh memuatkan semua jenis motosikal dengan sempurna. Daripada komponen rangka utama hingga bahagian enjin teras, semuanya memberikan jaminan kukuh untuk prestasi tinggi dan kestabilan motosikal.

Parameter produk

| Dimensi | Dimensi Tersuai |

| Bahan | Keluli, loyang, tembaga, aluminium, dll. |

| Rawatan permukaan | Menggilap, letupan pasir, mengecat, salutan serbuk, megalvani, penyaduran krom, dll. |

| Permohonan | Motosikal |

Proses Suai

Keperluan komunikasi

Reka Bentuk Produk

Membuat acuan

Penyediaan bahan

Penentuan proses

Pengeluaran Foundry

Pemprosesan pasca

Pemeriksaan dan penghantaran

Jenis Proses

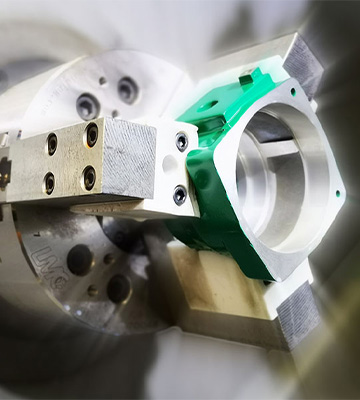

Teknik Keratan dengan Mesin Bubut

Memusing ialah proses pemesinan di mana bahan kerja berputar dan alat memusing bergerak dan memotong pada mesin pelarik. Ia boleh melakukan pelbagai operasi pusingan seperti bulatan luaran, lubang dalaman, benang dan muka hujung. Ia mempunyai ketepatan pemesinan yang tinggi dan kualiti permukaan yang baik, dan boleh memproses pelbagai bahan.

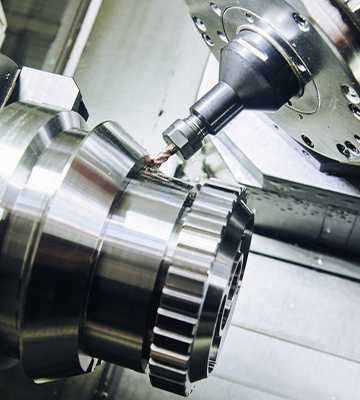

Proses pengilangan

Pengilangan adalah sejenis pemprosesan mekanikal, di mana putaran pemotong pengilangan adalah gerakan utama, dan pergerakan bahan kerja atau pemotong pengilangan adalah gerakan suapan. Ia boleh memproses pelbagai bentuk seperti satah, alur, dan permukaan membentuk. Ia mempunyai pelbagai alat, ketepatan dan kecekapan pemprosesan yang tinggi, dan digunakan secara meluas dalam bidang pembuatan mekanikal.

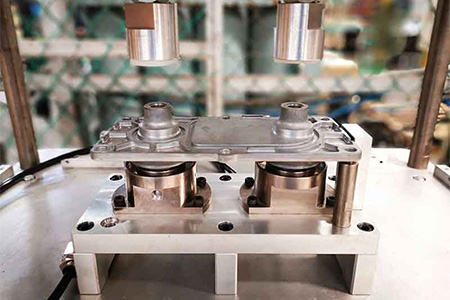

Tuangan die tekanan tinggi

Tuangan die tekanan tinggi ialah proses tuangan logam yang menggunakan tekanan tinggi untuk menyuntik logam cair dengan cepat ke dalam rongga acuan dan menyejukkannya sehingga terbentuk. Ia mempunyai kelebihan kecekapan pengeluaran yang tinggi, ketepatan tuangan yang baik, dan kualiti permukaan yang baik. Ia digunakan secara meluas dalam industri automotif, penerbangan dan lain-lain.

Material

Loyang

Keluli

Aluminium

Keluli

Kawalan Kualiti

- Kepakaran dan Pengalaman: Dengan pengalaman bertahun-tahun dalam industri, Sena Diecasting telah mengasah kemahiran dan kepakarannya, menjadikan kami nama yang dipercayai dalam diecasting.

- Teknologi Lanjutan: Kami menggunakan teknologi dan peralatan terkini untuk memastikan proses diecasting kami memenuhi standard kualiti dan kecekapan tertinggi.

- Perkhidmatan Komprehensif: Dari diecasting kepada kemasan dan penyaduran, Sena Diecasting menawarkan rangkaian penuh perkhidmatan untuk memenuhi semua keperluan anda.

Kemampuan proses

Kami menawarkan:

- Diecasting tekanan tinggi

- CNC ketepatan dan pemesinan konvensional

- Penyaduran krom dan kemasan permukaan lain

- Salutan serbuk automatik

- Impregnasi, jatuh, ujian kebocoran, pemasangan, dan jenis proses sekunder lain

- Salutan ED, pengecatan basah dan rawatan permukaan sumber luar yang lain

Proses tambahan

Proses menggilap

Penggilap mekanikal: Gunakan roda penggilap (diperbuat daripada kapas, bulu, kulit, dsb.) dan pes penggilap atau cecair penggilap (mengandungi bahan pelelas seperti aluminium oksida, silikon karbida, dsb. dan pelincir) untuk menggosok permukaan bahan kerja untuk mengeluarkan bonggol permukaan kecil dan menjadikan permukaan licin.