Product Description

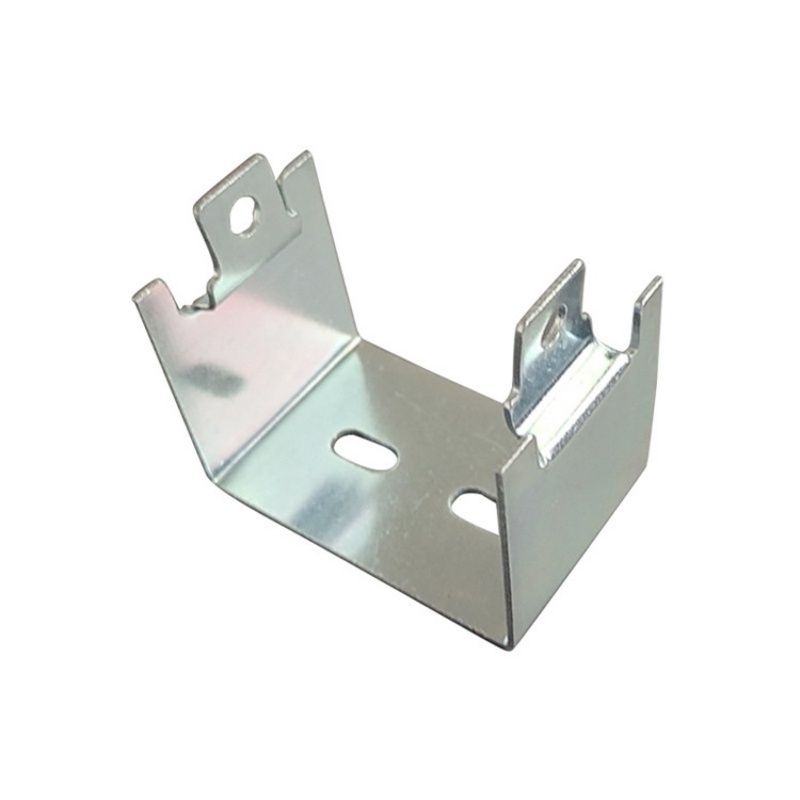

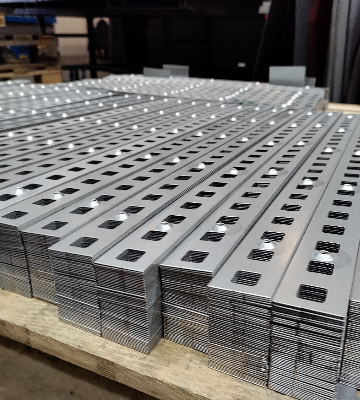

High-quality metal stamping parts, made from durable powder-coated steel to withstand harsh environments and heavy-duty applications. Designed for strength, precision, and long-lasting performance, these parts are suitable for use in various industries, including automotive, heavy machinery, construction, and industrial equipment.

Product parameters

| item | value |

| Feature | High crystallinity (HCPP), High flow, low temperature resistance, High sliding, standard grade |

| Application | automotive parts |

| color | OEM |

| Function | Waist |

| Product Name | Hand Dynamometer Grip Strength Trainer |

| Material | Silicone |

| Color | As shown in the picture or customized |

| Size | Unisex |

| Keywords | Hand Exerciser |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Process Type

Punching

Involves creating holes or cutouts in the workpiece using a punch and die set. The punch forces the material into the die to create the desired hole shape.

Flanging

Involves creating a flange or raised edge along the perimeter of a workpiece. It’s often used to strengthen or reinforce edges, or to make it easier to attach the stamped part to other components.

Trimming

Involves removing excess material from the edges of a stamped part, typically to refine its shape or size. This process is often performed after the initial stamping operations.

Material

Brass

Aluminum

Steel

Stainless steel

Quality Control

Our powder-coated stamped metal parts are subjected to stringent quality control procedures to ensure they meet exacting industry standards. From raw material selection to final inspection, we carefully monitor each stage of production using advanced measurement tools and testing equipment. The stamping process is checked for precision, ensuring consistent shapes and dimensions, while the powder coating is inspected for uniform coverage, adhesion, and durability to enhance corrosion resistance and appearance.

Processing capability

Our processing capability for powder-coated stamped metal parts includes high-precision stamping, cutting, bending, and deep drawing, allowing us to create components with complex geometries and tight tolerances. We can work with various metals, including steel, aluminum, and stainless steel, in different thicknesses, to accommodate a wide range of applications. The powder coating process provides a durable, corrosion-resistant finish available in various colors and textures, enhancing both functionality and aesthetics.

Additional processes

In addition to stamping and powder coating, we offer a variety of additional processes to enhance the functionality and appearance of our metal parts. These include machining, welding, threading, perforating, and heat treatment to improve strength and durability. We also provide surface finishing options such as grinding, polishing, and deburring to ensure smooth edges and high-quality finishes.