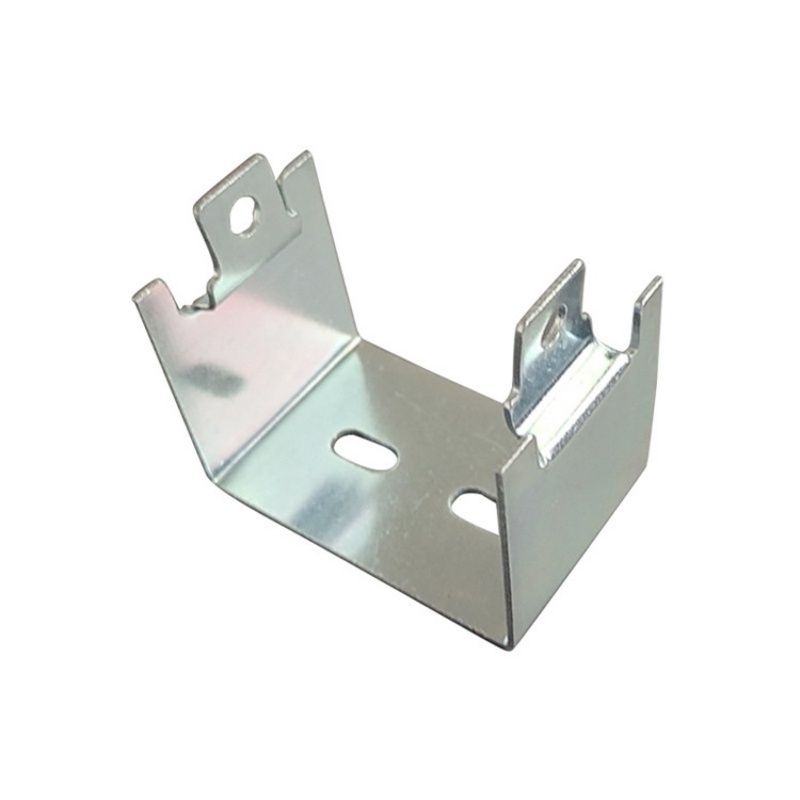

คำอธิบายผลิตภัณฑ์

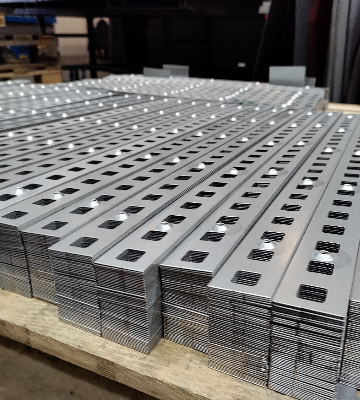

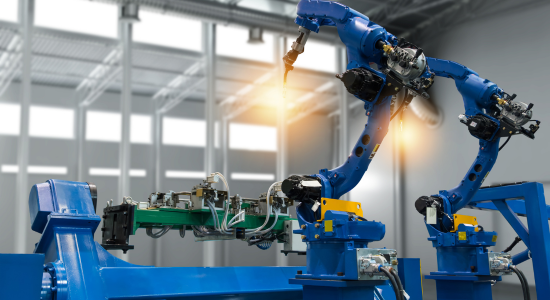

บริการปั๊มโลหะคุณภาพสูง รองรับขนาดต่างๆ และรูปแบบที่ซับซ้อน พร้อมบริการประกอบชิ้นส่วนทั้งหมด เราใช้เครื่องจักรขั้นสูงและช่างเทคนิคที่มีทักษะเพื่อให้มั่นใจถึงความแม่นยำและความทนทาน บริการของเราเหมาะอย่างยิ่งสำหรับอุตสาหกรรมยานยนต์ เครื่องจักร และอิเล็กทรอนิกส์ โดยมอบโซลูชันที่ปรับแต่งได้ตามความต้องการซึ่งตรงตามข้อกำหนดที่แน่นอน

พารามิเตอร์ผลิตภัณฑ์

| หมายเลขรุ่น | ตามแบบลูกค้า |

| คำสำคัญ (Keywords) | การดัดแผ่นเหล็กสเตนเลส |

| ขนาด | รับทำตามขนาดที่ลูกค้าต้องการ |

| ขั้นต่ำ (MOQ) | 1 ชิ้น |

| สี | สีที่กำหนดเองได้ |

| บรรจุภัณฑ์ | กล่องไม้ |

| เทคโนโลยี | การดัด, การเชื่อม, การเจาะ, การทำรู |

| คุณสมบัติเด่น | ทนต่อการกัดกร่อน |

| พื้นผิว | ขัดเงาและขัดเรียบ |

| ตัวอย่าง | มีบริการตัวอย่าง |

| ข้อดี | 1. บริการ OEM 2. ราคาแข่งขันได้ 3. คุณภาพดี |

กระบวนการที่กำหนดเอง

1. การสอบถาม

2. การออกแบบแม่พิมพ์

3. การทำแม่พิมพ์

4. การประทับตรา

5. การตรวจสอบมิติ

6. การตรวจสอบด้วยสายตา

7. แพ็คเกจ

8. การขนส่ง

ประเภทกระบวนการ

การต่อย

เกี่ยวข้องกับการเจาะรูหรือตัดชิ้นงานโดยใช้ชุดหัวเจาะและแม่พิมพ์ หัวเจาะจะดันวัสดุเข้าไปในแม่พิมพ์เพื่อสร้างรูปทรงรูที่ต้องการ

การจับเจ่า

เกี่ยวข้องกับการสร้างหน้าแปลนหรือขอบยกขึ้นตามขอบของชิ้นงาน มักใช้เพื่อเสริมความแข็งแรงหรือเสริมความแข็งแกร่งให้กับขอบ หรือเพื่อให้ติดชิ้นส่วนที่ปั๊มเข้ากับส่วนประกอบอื่นได้ง่ายขึ้น

การตัดแต่ง

เกี่ยวข้องกับการกำจัดวัสดุส่วนเกินออกจากขอบของชิ้นส่วนที่ปั๊ม โดยทั่วไปแล้วเพื่อปรับแต่งรูปร่างหรือขนาด กระบวนการนี้มักดำเนินการหลังจากการดำเนินการปั๊มเริ่มต้น

วัสดุ

ทองเหลือง

อลูมิเนียม

สตีล

สแตนเลส

การควบคุมคุณภาพ

บริการปั๊มและประกอบแผ่นโลหะที่มีความแม่นยำของเราช่วยให้ควบคุมคุณภาพได้ในระดับสูงสุดในทุกขั้นตอน เราใช้เครื่องมือและเทคนิคการตรวจสอบขั้นสูงเพื่อรับประกันความแม่นยำของขนาด ความสม่ำเสมอ และความทนทานของส่วนประกอบทั้งหมด ผลิตภัณฑ์แต่ละชิ้นต้องผ่านการทดสอบอย่างเข้มงวด รวมถึงการตรวจสอบด้วยสายตา การตรวจสอบพื้นผิว และการวัดที่แม่นยำเพื่อให้ตรงตามข้อกำหนดของลูกค้า

ความสามารถในการประมวลผล

บริการปั๊มและประกอบแผ่นโลหะที่มีความแม่นยำของเรามีความสามารถในการประมวลผลที่ครอบคลุม รวมถึงการดึงลึก การดัด การเจาะ การเจาะ และการเชื่อม เราจัดการกับวัสดุหลากหลายประเภท เช่น สแตนเลส อะลูมิเนียม และเหล็กกล้าคาร์บอน รองรับทั้งการออกแบบมาตรฐานและแบบกำหนดเอง ด้วยเครื่องจักรขั้นสูงและผู้ปฏิบัติงานที่มีทักษะ เราสามารถผลิตชิ้นส่วนที่ซับซ้อนที่มีค่าความคลาดเคลื่อนต่ำ ความหนาที่แตกต่างกัน และรูปทรงเรขาคณิตที่ซับซ้อน

กระบวนการอื่น ๆ

นอกจากการปั๊มและการประกอบแล้ว เรายังมีกระบวนการเพิ่มเติมอีกมากมายเพื่อเพิ่มประสิทธิภาพของผลิตภัณฑ์และตอบสนองความต้องการเฉพาะ ซึ่งได้แก่ การชุบผิว เช่น การเจียร การขัด การเคลือบผง และการชุบอะโนไดซ์ เพื่อปรับปรุงรูปลักษณ์และทนต่อการกัดกร่อน นอกจากนี้ เรายังให้บริการเครื่องจักรกลที่มีความแม่นยำ การทำเกลียว การลบคม และการชุบด้วยความร้อน เพื่อให้แน่ใจว่าส่วนประกอบแต่ละชิ้นตรงตามมาตรฐานการทำงานที่แน่นอน