Product Description

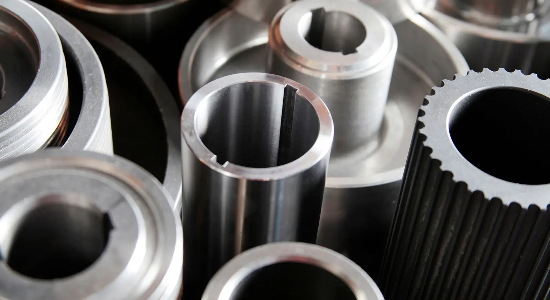

Our Custom Investment Casting services deliver high-precision metal parts with exceptional detail and surface finish. Using the lost-wax method, we can cast complex geometries in a variety of metals, including stainless steel, aluminum, and alloys. This process allows for intricate designs, reducing the need for extensive machining. We offer rapid prototyping, low to high-volume production, and custom alloy formulations. Our strict quality control ensures that every part meets industry standards for strength and durability. The smooth finish minimizes the need for secondary operations, saving time and cost. We provide casting solutions for industries such as aerospace, automotive, and medical devices. Our team works closely with clients to meet specific design and material requirements. With quick lead times and cost-effective solutions, we deliver high-quality results. Trust us for reliable, precise, and durable investment casting solutions tailored to your needs.

Product parameters

| List | Details |

|---|---|

| Service | CNC Turning, CNC Milling, Laser Cutting, Bending Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Die Casting |

| Materials | Aluminum / Stainless steel / Steel / Brass / Titanium |

| Size or shape | According to customer drawings or requests |

| Tolerance | Highest = +/-0.005mm or +/- 0.0002 inch |

| Drawing accepted | Stp, step, igs, iges, x_t, sat, stl, sldxml, prt, ipt, dxf, dwg, PDF, jpg, jpeg, png, etc. |

| Surface Treatment | Anodizing, Bead blasting, Si6%creen, PVD Plating,Zinc/Nickel/Chrome/ Titanium Plating,Brushing, Painting,Powder Coating,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave Etc. |

| Delivery | DHL, FedEx, EMS, UPS, or customer's requirements |

| Package | Inner pearl button,wooden case,or customized. |

Custom Process

Upload your design

Design analysis

Start production

Receive your parts

Process Type

Sheet Metal Fabrication

The process of transforming flat sheets of metal into various shapes and structures through techniques such as cutting, bending, punching, and welding. This method is widely used in the manufacturing of components for industries like automotive, construction, aerospace, and electronics. By utilizing machines like laser cutters, CNC presses, and brake presses, sheet metal fabrication offers high precision and flexibility in producing both simple and complex designs. It can be performed on a range of metals, including steel, aluminum, copper, and stainless steel, making it ideal for a variety of applications such as chassis, enclosures, and structural supports. The process is valued for its efficiency, cost-effectiveness, and ability to produce durable, lightweight parts. Sheet metal fabrication plays a critical role in modern manufacturing, allowing for the mass production of functional and aesthetically pleasing products.

Surface Treatment

Refers to a variety of processes used to modify the surface of materials, particularly metals, to enhance their properties and performance. These processes are designed to improve qualities such as corrosion resistance, wear resistance, hardness, adhesion, and aesthetic appeal. Common surface treatments include plating (e.g., zinc, nickel, or chrome), anodizing, powder coating, painting, polishing, and laser surface hardening. Surface treatment is essential in industries like automotive, aerospace, electronics, and medical devices, where components must withstand harsh environments or have a specific appearance. These treatments can also improve the durability and lifespan of parts, reduce friction, and prevent oxidation, which is crucial for maintaining the functionality of products over time. By modifying the surface at a microscopic level, surface treatment can also promote better bonding of coatings or adhesives, contributing to the overall performance and longevity of the material or component.

CNC Machining

Highly precise manufacturing process that uses computerized systems to control machine tools such as mills, lathes, and routers. By converting digital designs into detailed mechanical instructions, CNC machining allows for the creation of complex parts and components with high accuracy and repeatability. This technology is widely used in industries such as aerospace, automotive, medical devices, and electronics, offering significant advantages in terms of speed, precision, and the ability to produce intricate parts with minimal human intervention. The process can handle a variety of materials, including metals, plastics, and composites, making it versatile for various applications. CNC machining has revolutionized manufacturing by increasing efficiency, reducing waste, and allowing for consistent production of high-quality parts.

Material

Stainless steel

Aluminum

Titanium

Brass

Additional processes

Our Custom Investment Casting capabilities offer high-precision metal parts with complex geometries and excellent surface finishes. We handle a wide range of materials, including stainless steel, aluminum, brass, and special alloys. The lost-wax casting process allows for intricate designs with minimal material waste. We offer rapid prototyping, low-volume, and high-volume production runs. Our advanced techniques ensure tight tolerances and dimensional accuracy, often without the need for additional machining. Post-casting processes like heat treatment, surface finishing, and coating are available to enhance durability and performance. We support a variety of industries, including aerospace, automotive, and medical. Our team uses cutting-edge CAD/CAM software to optimize the design and manufacturing process. With quick turnaround times and strict quality control, we deliver reliable, cost-effective solutions. We ensure high-quality results, from design to final product, tailored to customer specifications.