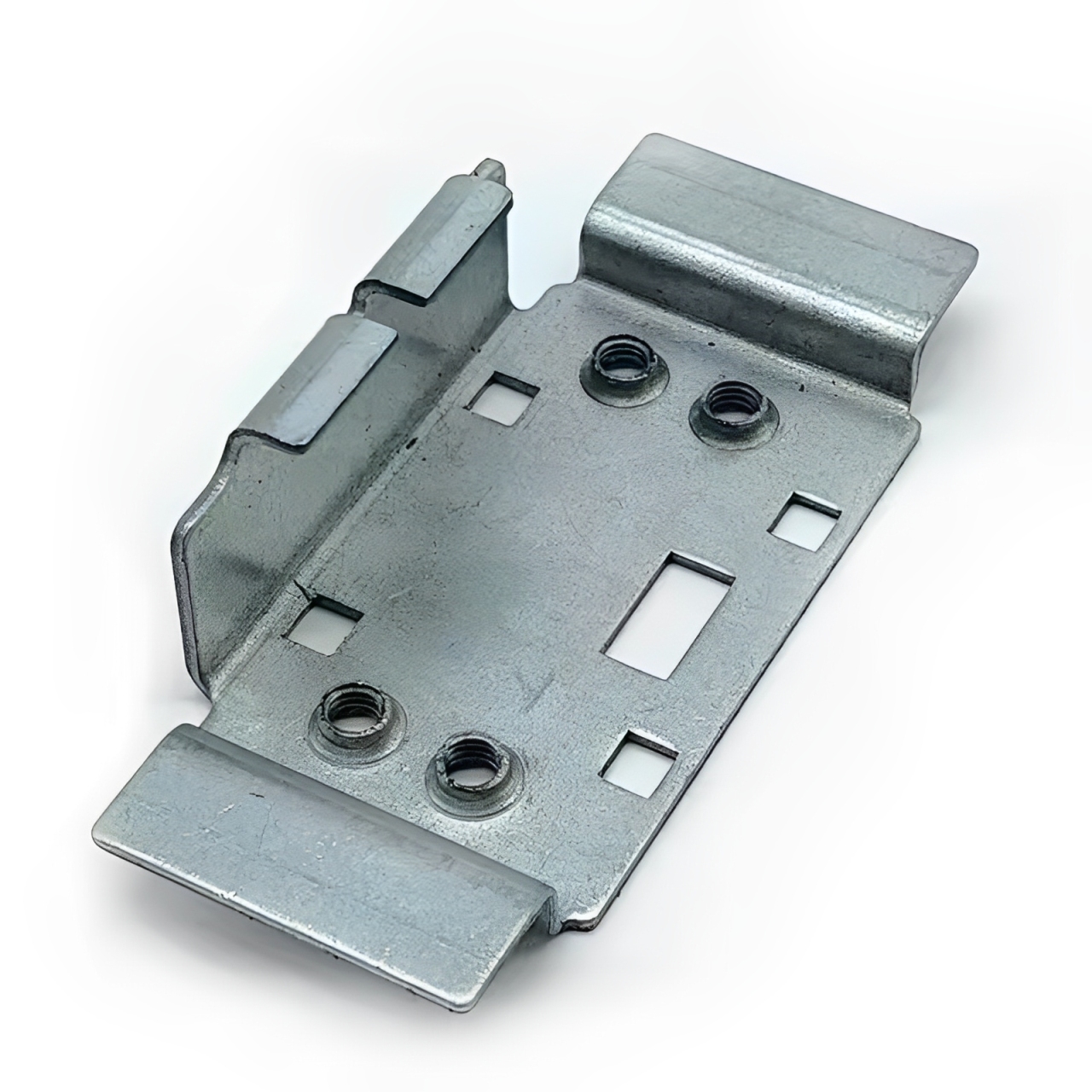

Paglalarawan ng Produkto

Makabagong cylindrical bowl na may mataas na precision machining, dalubhasang ginawa nang walang slotting upang matiyak ang pinakamainam na integridad ng istruktura at maayos na functionality. Dinisenyo para sa tibay, ang produktong ito ay ginawa upang mapaglabanan ang kahirapan ng mga pang-industriyang aplikasyon habang naghahatid ng tumpak at pare-parehong pagganap. Ang makinis na disenyo at walang kamali-mali na pagtatapos nito ay nagbabawas sa panganib ng pagkasira, na tinitiyak ang mahabang buhay at pagiging maaasahan. Angkop para sa malawak na hanay ng makinarya, ang cylindrical na mangkok na ito ay nag-aalok ng pambihirang dimensional na katumpakan at mga pagpipilian sa pagpapasadya upang matugunan ang mga partikular na pangangailangan sa pagpapatakbo.

Mga parameter ng produkto

| Laki ng Produkto (Diameter * Taas) | ¢394*217.4 |

| Katangian | Mahabang Buhay ng Serbisyo, Precision, Matibay, Eco-friendly, Sustainable |

| Serbisyo | OEM na Pasadyang Pag-customize |

| Bentahe | Propesyonal na Teknolohiya, Mataas na Kalidad |

Custom na Proseso

1.magpadala ng mga katanungan

2.mga guhit o sample

3. Sipi

4.pagkumpirma ng customer

5. naglalagay ng order at nagbabayad

6.Mass production

7. Subukan bago ang packaging

8. Pagpapadala at pagkumpirma

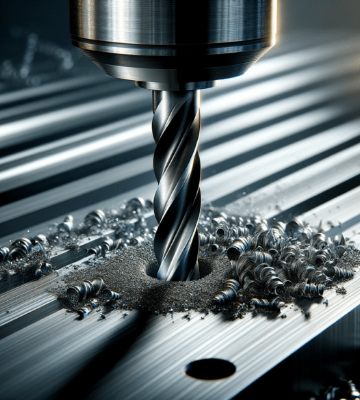

Uri ng Proseso

Deburring

Pagbabarena

Die Casting

Materyal

Aluminum Alloy

Hindi kinakalawang na asero

tanso

tanso

Kontrol sa Kalidad

Ang kontrol sa kalidad ng High Precision Machined Cylindrical Bowl ay isang komprehensibong proseso na nagsisiguro na ang bawat produkto ay nakakatugon sa mga eksaktong pamantayan. Nagsisimula ito sa pagpili ng mga premium-grade na materyales, na sinusundan ng precision machining sa ilalim ng mahigpit na pangangasiwa upang makamit ang walang kamali-mali na katumpakan ng dimensyon at makinis na pagtatapos. Ang mga advanced na tool sa inspeksyon, tulad ng mga coordinate measuring machine (CMM), ay ginagamit upang i-verify ang mga tolerance at kalidad ng ibabaw.

Kakayahan sa pagproseso

The processing capability of the High Precision Machined Cylindrical Bowl includes advanced CNC machining techniques that allow for the production of highly accurate and complex shapes. This capability ensures tight tolerances and a high-quality finish, even for intricate designs. The use of high-precision milling and turning allows for the precise shaping of the cylindrical bowl, while maintaining consistency across both small and large production runs.

Mga karagdagang proseso

Ang mga karagdagang proseso para sa High Precision Machined Cylindrical Bowl ay nagpapahusay sa functionality at tibay nito. Pagkatapos ng pangunahing machining, ang mga surface treatment gaya ng anodizing o coating ay inilalapat upang pahusayin ang corrosion resistance at wear resistance, na tinitiyak ang pangmatagalang performance sa malupit na kapaligiran. Maaaring gamitin ang heat treatment upang higit na palakasin ang materyal, pataasin ang katigasan nito at kapasidad na nagdadala ng pagkarga.