Deskripsi Produk

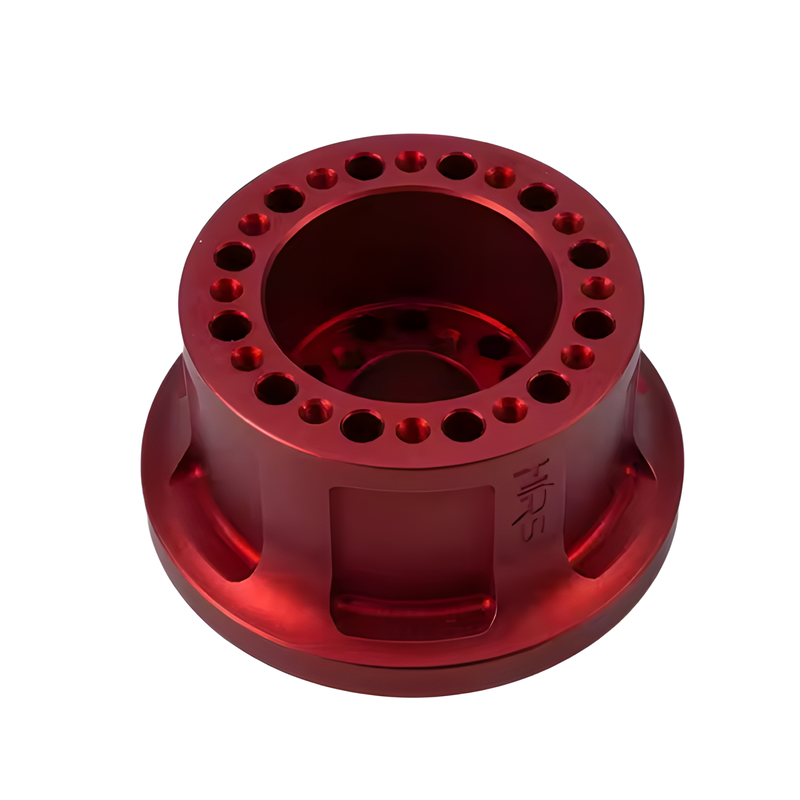

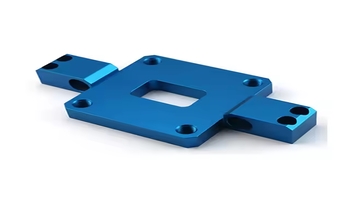

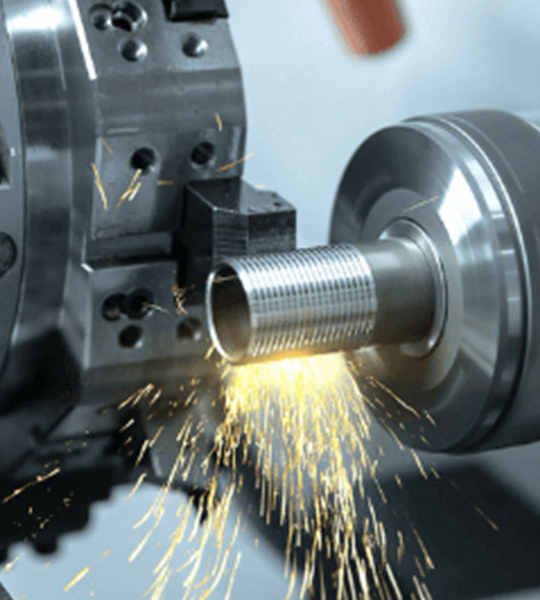

CNC Kustom Presisi Tinggi menawarkan solusi pemesinan yang disesuaikan dengan akurasi luar biasa dan toleransi ketat. Layanan ini melayani berbagai industri, termasuk dirgantara, otomotif, dan medis. Dengan memanfaatkan teknologi CNC canggih, proses ini memastikan desain rumit dan hasil akhir yang superior. Proses ini mendukung berbagai bahan seperti logam, plastik, dan komposit. Ini ideal untuk produksi dalam jumlah kecil maupun besar. Terpercaya dan hemat biaya, layanan ini menghasilkan bagian kustom yang memenuhi kebutuhan spesifik.

Parameter produk

| Daftar | Rincian |

|---|---|

| Nama Produk | Bagian Kustom |

| Kemampuan Material | Aluminium, Kuningan, Perunggu, Tembaga, Logam Keras, Logam Mulia, Baja Tahan Karat, Paduan Baja |

| Tipe | Broaching, PENGBORAN, Ukiran / Pemesinan Kimia, Pemesinan Laser, Pemesinan, Layanan Pemesinan Lainnya, Pembubutan, Wire EDM, Prototipe Cepat |

| Material | Logam/Tembaga/Aluminium/Baja Tahan Karat/Kuningan dll. |

| Aplikasi | Peralatan Industri |

| Proses | Lembar logam + deburring + pembengkokan |

| Perawatan Permukaan | Pelapisan Seng/Nikel/Krom/Plating Tembaga, Pelapisan Hitam, Anodisasi |

| Peralatan | Pusat Pemesinan 3/4/5 Axis |

Proses kustomisasi

Unggah desain Anda

Analisis desain

Mulai produksi

Terima bagian Anda

Jenis Proses

Pengerjaan CNC

Fabrikasi logam lembaran

Perlakuan permukaan

Bahan

Aluminium

Kuningan

Tembaga

Proses tambahan

CNC Kustom Presisi Tinggi mampu menghasilkan bagian rumit dengan toleransi yang sangat ketat, sering kali dalam skala mikron. Proses ini dapat menangani berbagai bahan, termasuk logam, plastik, dan komposit. Mendukung geometri kompleks, memastikan hasil akhir permukaan berkualitas tinggi. Teknologi CNC menjamin repetibilitas dan konsistensi dalam berbagai run produksi. Ini ideal untuk prototyping maupun manufaktur skala besar. Kemampuan ini juga mencakup berbagai operasi pemesinan seperti frais, bubut, bor, dan ukir.