Product Description

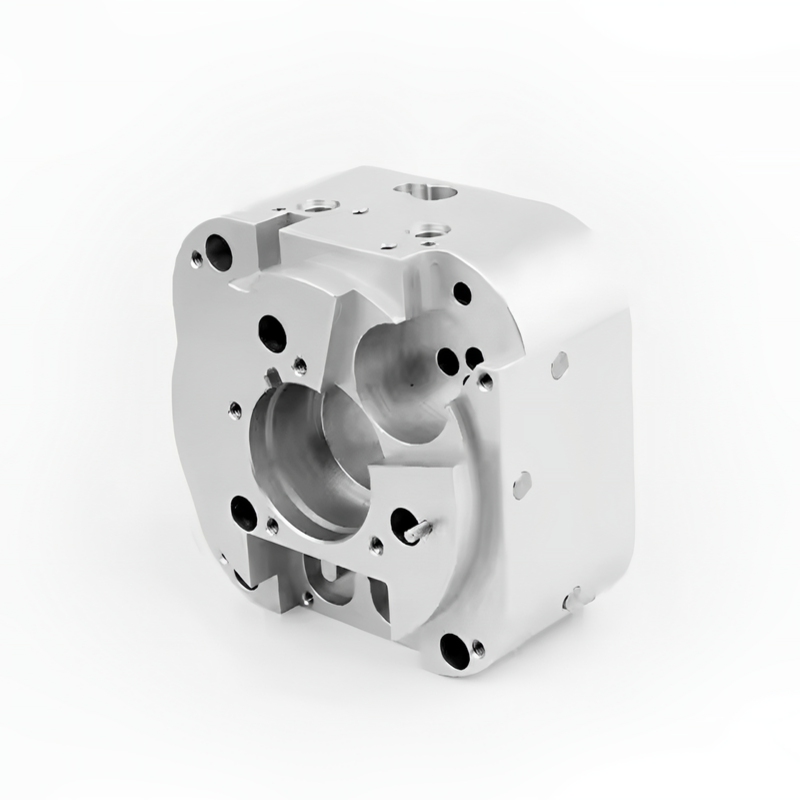

Precise, strong, and durable machined forged parts, manufactured to order for CNC and lathe machines, suitable for industries that require high precision and standard quality. These custom-forged components are crafted with advanced forging techniques, ensuring exceptional strength, reliability, and performance in demanding applications. Ideal for automotive, aerospace, and industrial machinery, our forged parts offer superior resistance to wear and fatigue, providing long-lasting durability and optimal functionality.

Product parameters

Materials Available

| Alloy steel | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

| Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416, 17-4PH,etc. |

| Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, 1012#,etc. |

| Brass | C35600, C36000, C37700, C37000, C37100, C28000, C26000 etc. |

| Copper | C11000, C12000, C12200, C10100, etc. |

| Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic | POM, PEEK, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, PETF(Telflon) etc |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Robotic Equipment

Electric Vehicles

Industrial Machinery

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control of Precision Forged Flange ensures that each component meets the highest standards of strength, durability, and accuracy. From the initial material selection to the final inspection, every stage of the manufacturing process is carefully monitored. Our rigorous testing procedures, including dimensional checks, material hardness, and stress resistance evaluations, guarantee the product’s performance in demanding applications.

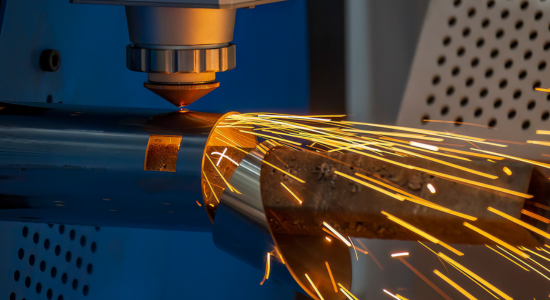

Processing capability

The processing capability of Precision Forged Flange includes advanced forging techniques that allow for the production of high-quality, custom-made components tailored to specific requirements. Using state-of-the-art machinery and skilled craftsmanship, we can handle various materials and sizes, ensuring precise and consistent results. The forging process ensures superior strength and durability, while CNC and lathe machining capabilities allow for intricate and accurate shaping of the flanges to meet tight tolerances.

Additional processes

Additional processes for Precision Forged Flange include heat treatment, surface finishing, and post-forging machining to enhance the strength, durability, and appearance of the components. Heat treatment processes such as annealing and quenching are applied to improve the material’s hardness and resistance to wear. Surface finishing techniques, such as polishing or coating, ensure a smooth, corrosion-resistant surface that meets industry standards. Post-forging machining is performed to achieve precise dimensions and tolerances, ensuring the flanges fit seamlessly into the required applications.