Mô tả sản phẩm

Tập trung vào lĩnh vực tùy chỉnh đúc, chúng tôi có thể cung cấp cho bạn hợp kim nhôm phi tiêu chuẩn chất lượng cao, đúc áp lực thép không gỉ và đúc chính xác thép cacbon. Dựa vào thiết bị tiên tiến và công nghệ tinh xảo, cho dù là tùy chỉnh hợp kim nhôm phi tiêu chuẩn phức tạp hay đúc áp lực thép không gỉ và đúc chính xác thép cacbon với yêu cầu độ chính xác cực cao, chúng tôi có thể kiểm soát chặt chẽ từng quy trình để đảm bảo kích thước sản phẩm chính xác, hiệu suất ổn định và chất lượng đáng tin cậy, đáp ứng nhu cầu công nghiệp đa dạng của bạn và sử dụng sức mạnh để tạo ra các sản phẩm đúc đáng tin cậy.

Thông số sản phẩm

| Màu sắc | Màu tùy chỉnh |

| Kích cỡ | Bản vẽ 3D của khách hàng |

| Vật liệu | Thép, đồng, nhôm, sắt, hợp kim, v.v. |

| Đặc điểm | Mạnh mẽ, bền bỉ, tuổi thọ cao |

Quy trình tùy chỉnh

1.Liên hệ với dịch vụ khách hàng

2.Xác nhận thông số kỹ thuật

3.Thanh toán tiền đặt cọc

4.Sắp xếp sản xuất

5.Kiểm tra chất lượng

6.Thanh toán khoản thanh toán cuối cùng

7.Sắp xếp giao hàng

8.Xác nhận đã nhận hàng

Loại quy trình

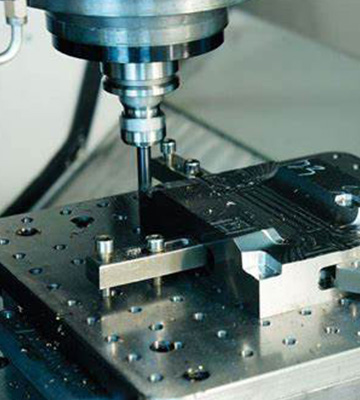

Quá trình phay

Dao phay quay và phôi được đưa vào để cắt vật liệu. Nó có thể gia công nhiều hình dạng khác nhau như mặt phẳng và rãnh với độ chính xác cao. Nó thường được sử dụng trong sản xuất máy móc, gia công khuôn mẫu và các ngành công nghiệp khác.

Quá trình tiện

Máy tiện dẫn động phôi quay, dao thực hiện chuyển động đưa phôi vào, chủ yếu gia công các chi tiết quay có độ chính xác cao, độ nhám thấp, được sử dụng rộng rãi trong gia công các chi tiết trục và đĩa.

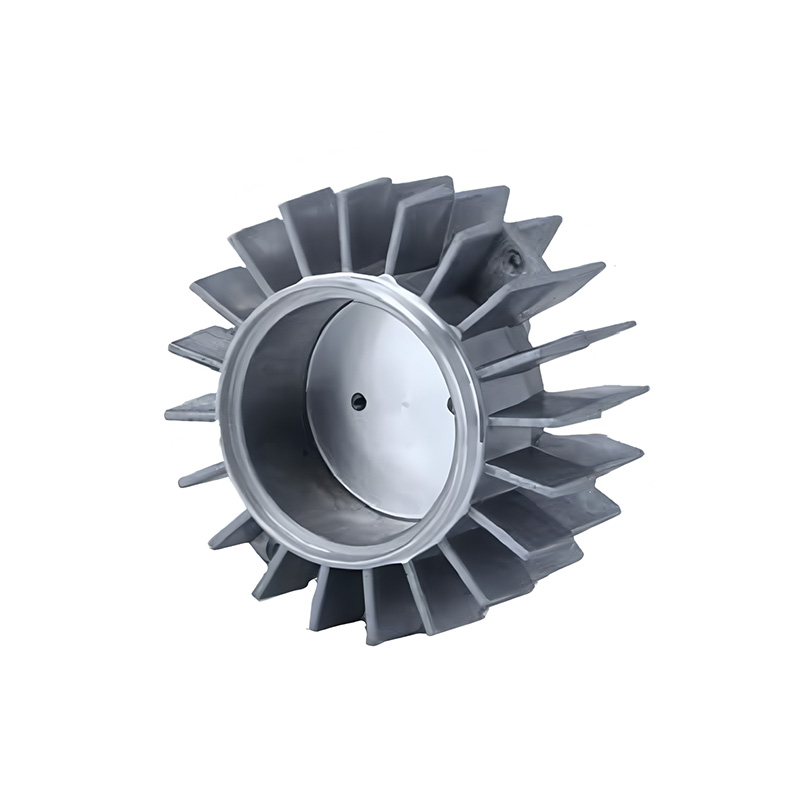

Đúc áp lực

Kim loại lỏng hoặc bán lỏng được ép vào khoang khuôn ở tốc độ cao dưới áp suất cao và đúc sau khi làm nguội và đông đặc. Nó có thể sản xuất đúc có hình dạng phức tạp, hiệu quả cao và được sử dụng trong nhiều ngành công nghiệp để chế tạo các bộ phận phức tạp

Chất liệu

Sắt

Nhôm

Thép không gỉ

Hợp kim nhôm

Kiểm soát chất lượng

Chất lượng là ưu tiên hàng đầu của chúng tôi, đó là niềm tin mà chúng tôi luôn tuân thủ. Chúng tôi bắt đầu từ nguồn và lựa chọn nguyên liệu thô chất lượng cao để đảm bảo chất lượng cơ bản của sản phẩm. Chúng tôi áp dụng công nghệ đúc áp lực tiên tiến và kết hợp với thiết bị sản xuất thông minh để đạt được sự quản lý tinh tế của quy trình sản xuất. Đồng thời, chúng tôi được trang bị đội ngũ kiểm tra chất lượng chuyên nghiệp và sử dụng các phương pháp thử nghiệm khoa học để tiến hành kiểm tra chất lượng nghiêm ngặt đối với sản phẩm, không bỏ sót bất kỳ sai sót nào. Chúng tôi tạo ra giá trị lớn hơn cho khách hàng của mình bằng các sản phẩm chất lượng cao.

Khả năng xử lý

TBD có khả năng gia công tuyệt vời. Về mặt kiểm soát độ chính xác, với thiết bị tiên tiến và tay nghề thủ công tinh xảo, độ chính xác về kích thước có thể đạt đến cấp độ micron và dung sai về hình dạng và vị trí cực kỳ nhỏ, đảm bảo sản phẩm hoàn toàn phù hợp với thiết kế. Cũng có thể đạt được các cấu trúc phức tạp và có thể chế tạo được các bộ phận có khoang mịn và thành siêu mỏng. Về mặt vật liệu, nó bao gồm tất cả các loại kim loại để đáp ứng các nhu cầu đa dạng. Từ các bộ phận chính xác nhỏ đến các thành phần công nghiệp lớn, phạm vi kích thước gia công là lớn. Có thể điều chỉnh tùy chỉnh lô nhỏ một cách linh hoạt và sản xuất quy mô lớn cũng có thể được hoàn thành hiệu quả, cung cấp các sản phẩm đúc chính xác chất lượng cao cho nhiều ngành công nghiệp khác nhau.